Back cover displacement type torque amplifier

A torque amplifier and displacement technology, applied in the direction of fluid pressure actuating device, servo motor, servo motor assembly, etc., can solve the problems of single connection method, limited application scope, and inability to install flexibly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

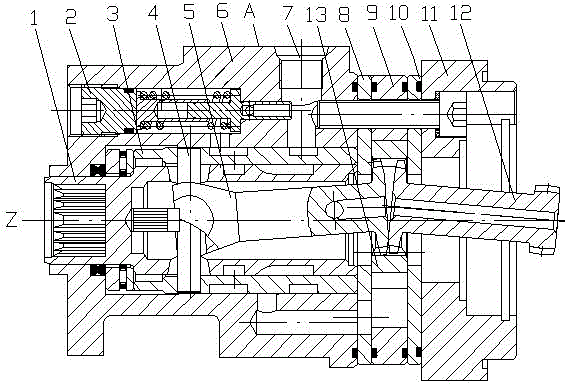

[0015] The rear cover displacement type torque amplifier of the present embodiment is as figure 1 with figure 2 As shown, the base plane A of the housing 6 has an oil inlet and an oil return port 7, and the housing 6 is fixed along the main axis Z direction with the stator 9 and the rear cover 11 clamped by the front partition 9 and the rear partition 10 connect. A valve core sleeve 3 supporting the valve core 1 is housed in the housing 6, and a rotor 13 forming a cycloidal pin-wheel pair is housed in the stator 9. The inner hole of the rotor 13 is meshed with the opposite ends of the input linkage shaft 5 and the output linkage shaft 12 through an inner spline. The other end of the input linkage shaft 5 is connected to the valve core sleeve 3 through the dial pin 4 , and the other end of the output linkage shaft 12 passes through the rear cover 11 . Figure 2 is a safety overflow valve installed on one side of the housing.

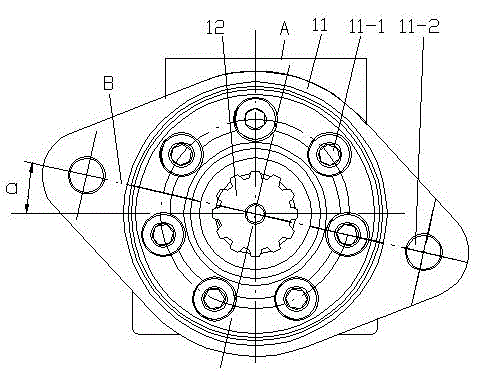

[0016] The rear cover 11 has seven perforations...

Embodiment 2

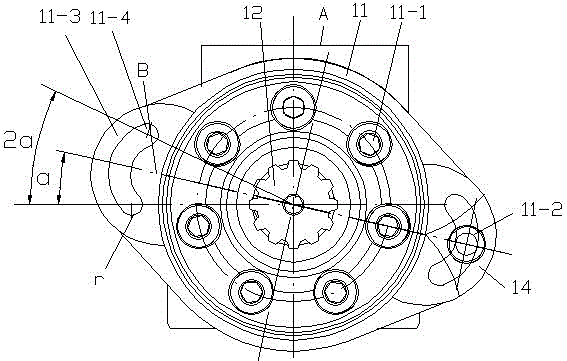

[0018] The basic structure of the rear cover displacement type torque amplifier of this embodiment is the same as that of Embodiment 1, the differences are as follows image 3 , 4 , 5, the back cover 11 is respectively formed with a base circle depression 11-3 corresponding to the two installation holes, and the base circle depression 11-3 is formed with an arc groove 11-4 adapted to the position of the installation hole, and the arc groove 11- The center line of symmetry of 4 passes through the center of one of the through holes 11-1 and forms an included angle a=(360°÷7) / 2 with the radial direction of the main axis parallel to the reference plane. Both ends of the arc groove 11-4 are transitional semicircles r, and the center angle of the center of the transitional semicircle at both ends corresponding to the main axis is 2a. The base circle recess 11-3 is embedded with an insert 14 whose outer contour matches the base circle and has a mounting hole 11-2.

[0019] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com