Touch screen and LCD (liquid crystal display) module attaching jig group and attaching method

A technology for liquid crystal modules and lamination fixtures, applied in optics, instruments, electrical and digital data processing, etc., can solve the problems of inability to guarantee the size of the backlight module, and the inconsistent size of the border around the display area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

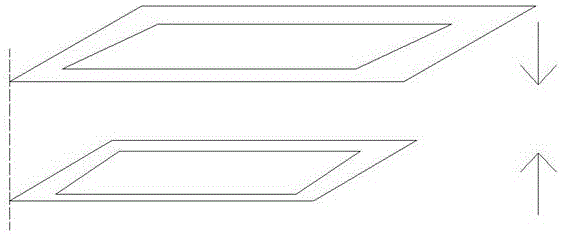

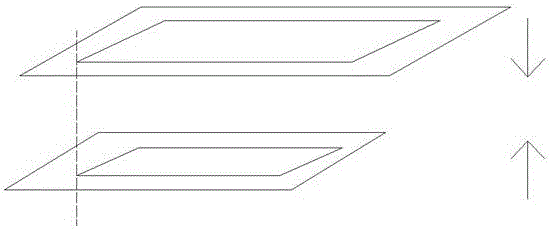

[0036] see Figure 5 to Figure 8 , the present invention provides a touch screen and liquid crystal module bonding jig set, which can well solve the problems in the prior art that the size of the borders around the display area of the liquid crystal module is inconsistent and the overall size of the backlight module cannot be guaranteed. . The jig set includes: a first jig 20 for bonding the liquid crystal panel and the touch screen that have not yet been assembled with the backlight module, and a whole body and the backlight module for bonding the liquid crystal panel and the touch screen together The second jig 40 bonded together.

[0037] Specifically, the first jig 20 includes: a first bottom plate 22, and four first positioning blocks 24 respectively connected to the four corners of the first bottom plate 22, and the first positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com