Seamless underwear machine valve group distributed drive control system and control method

A seamless underwear machine, drive control technology, applied in general control system, control/adjustment system, computer control, etc., can solve problems such as poor scalability and anti-interference, complex control lines, and affecting working characteristics, etc., to achieve Improve real-time performance and stability, reduce operating current, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

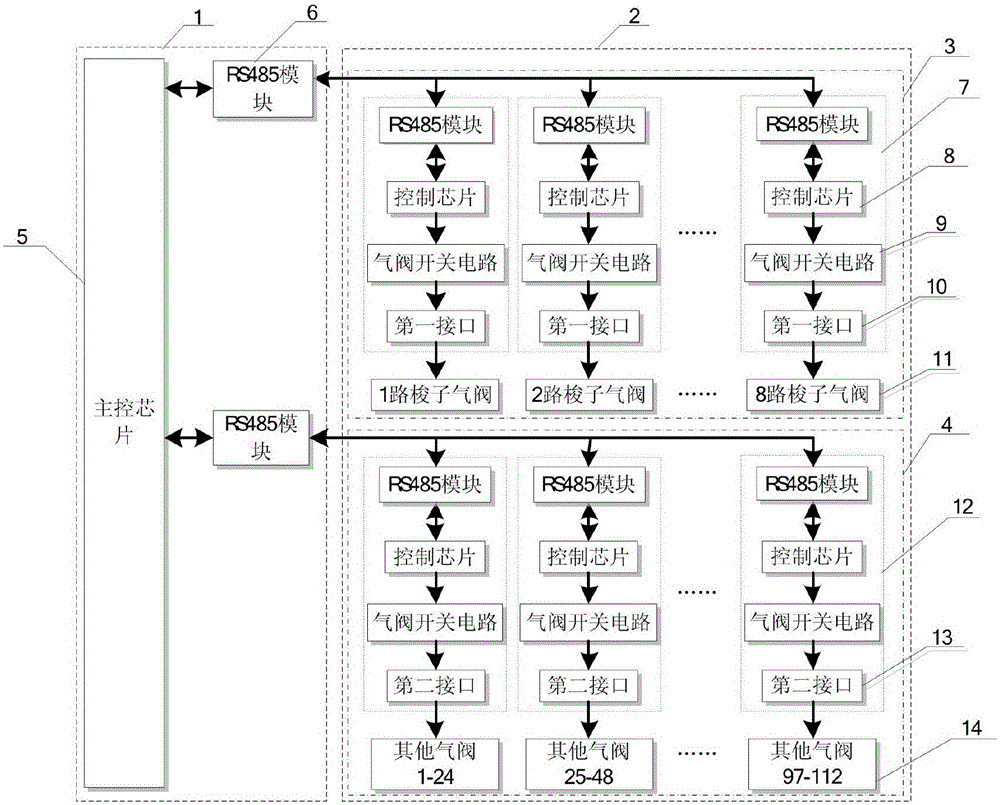

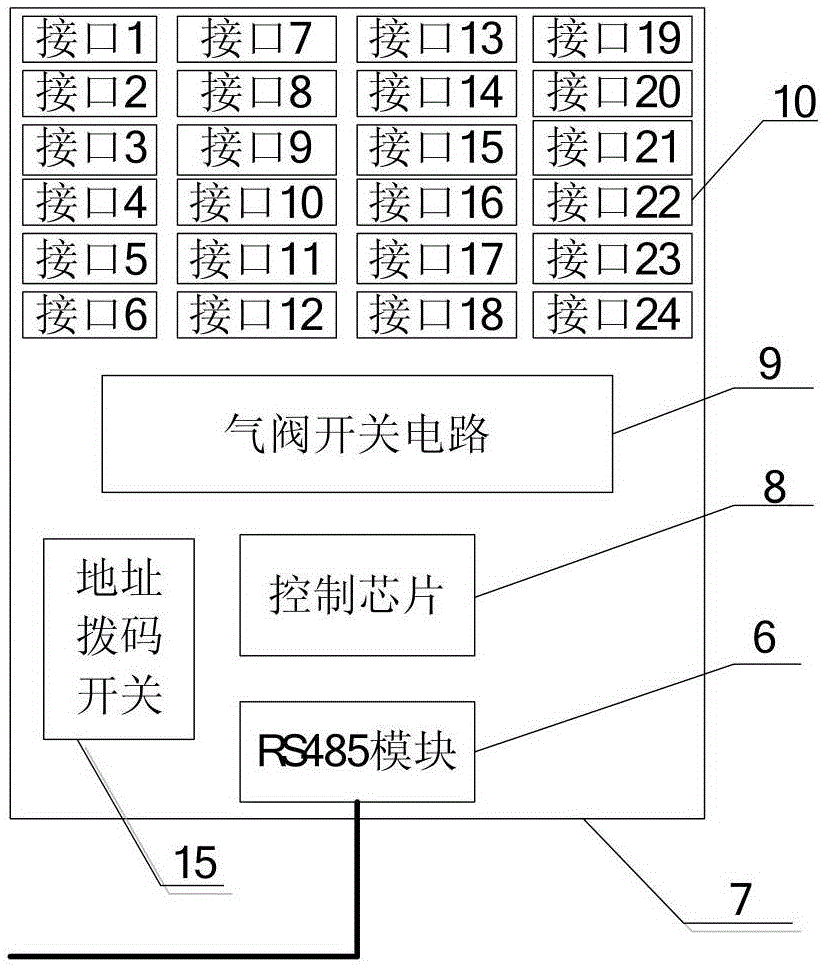

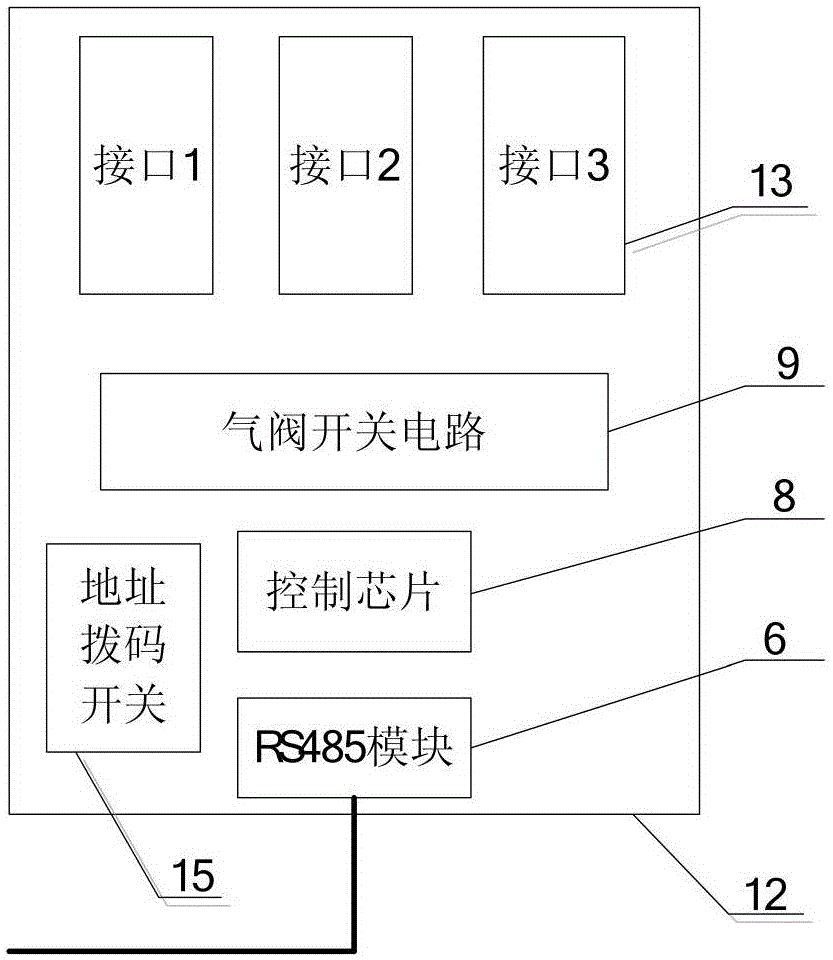

[0027] A distributed drive control system for the air valve group of a seamless underwear machine in this embodiment, such as figure 1 , 2 , 3, including main control layer 1 and execution layer 2; said main control layer 1 and execution layer 2 are respectively connected by 2-way RS485 buses; said main control layer 1 includes main control chip 5, and main control chip 5 2 RS485 modules 6 connected by lines respectively, the main control chip 5 model used in this embodiment is STM32F407; the execution layer 2 includes 8 groups of shuttle gas valve groups 3 and 5 groups of other gas valve groups 4, wherein the shuttle gas valve groups The valve group 3 and other gas valve groups 4 are respectively connected to an RS485 module 6 on the main control layer 1 through an RS485 bus; the 8 groups of shuttle gas valve groups 3 in this embodiment include 8 shuttle gas valve plates 7, 120 shuttle air valves 11 connected with the shuttle air valve plate 7; said 5 groups of other air val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com