Full-automatic detection pin cutter for capacitors

A capacitor, fully automatic technology, used in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as eye fatigue, a lot of manpower and equipment, and achieve the effect of reducing human misjudgments, eliminating errors, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

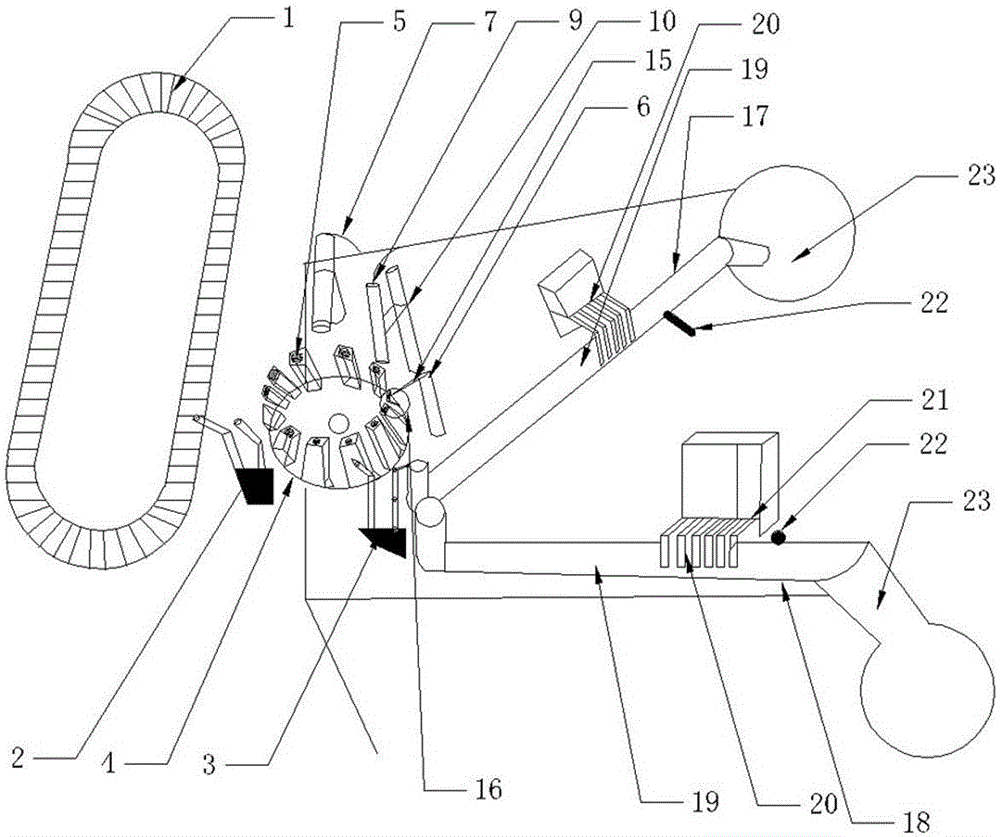

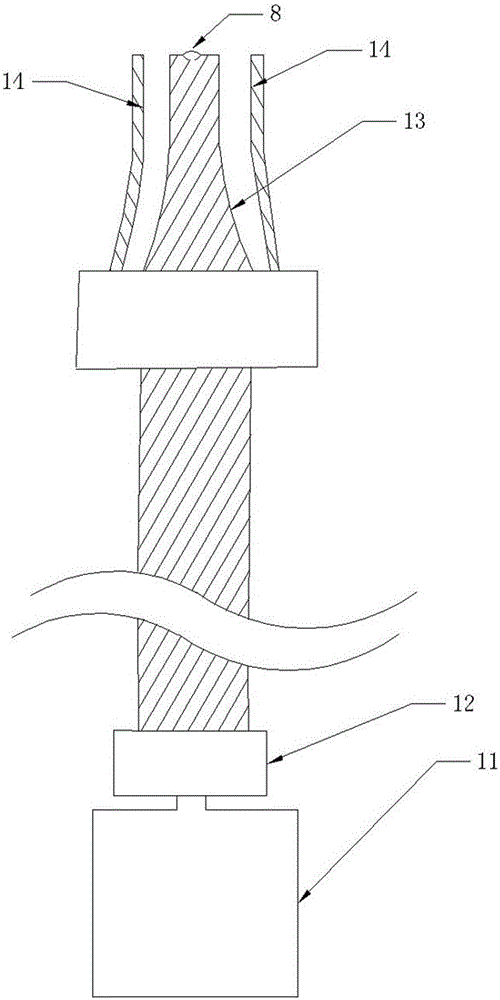

[0022] like figure 1 and figure 2 A fully automatic detection and cutting machine for capacitors is shown, including a ring-shaped aging output chain 1 provided with electrical performance detection, a feeding manipulator 2, an appearance inspection device, a material unloading manipulator 3, a cutting foot conveying device, and a feeding device connected in sequence. The manipulator 2 packs the capacitor after the aging electrical performance test into the appearance detection device, and the unloading manipulator 3 packs the capacitor after the appearance test into the foot cutting conveying device for cutting. The appearance inspection device includes a rotating chassis 4, a capacitor rotating assembly 5 arranged on the rotating chassis 4, a rejecting device 6 arranged above the rotating chassis, a side detector 7, a bottom detector 8 and an upper detector 9; the feeding manipulator 2 will The CP line of the capacitor after the aging electrical performance test is transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com