Gigohm-level anti-explosion and combustion-proof cover cap of power battery

A power battery, geo-level technology, applied in the field of European-level explosion-proof and anti-combustion caps, can solve the problems of easy deformation and rupture of explosion-proof film, easy combustion of batteries, short service life, etc., to improve safety and anti-explosion performance, without explosion and combustion hazards , the effect of reducing the overall internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment to this invention for further clarification.

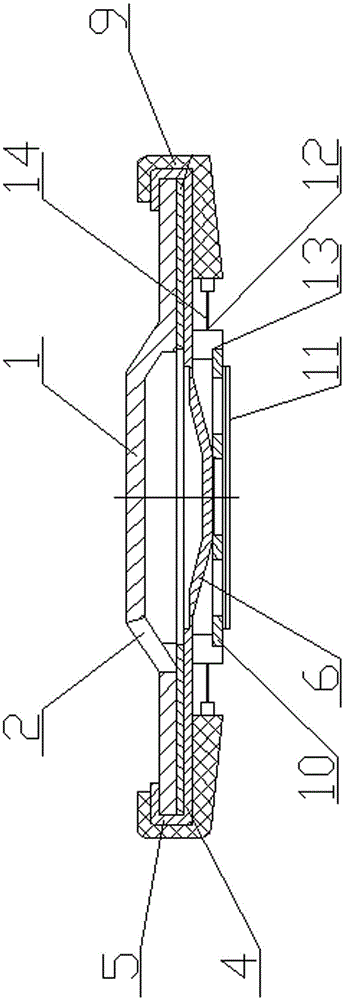

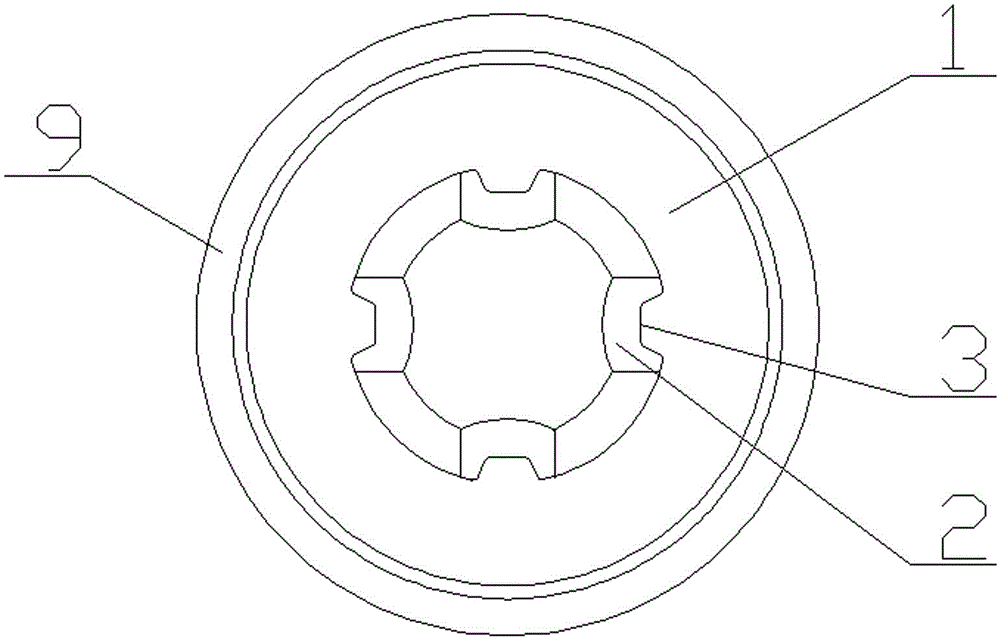

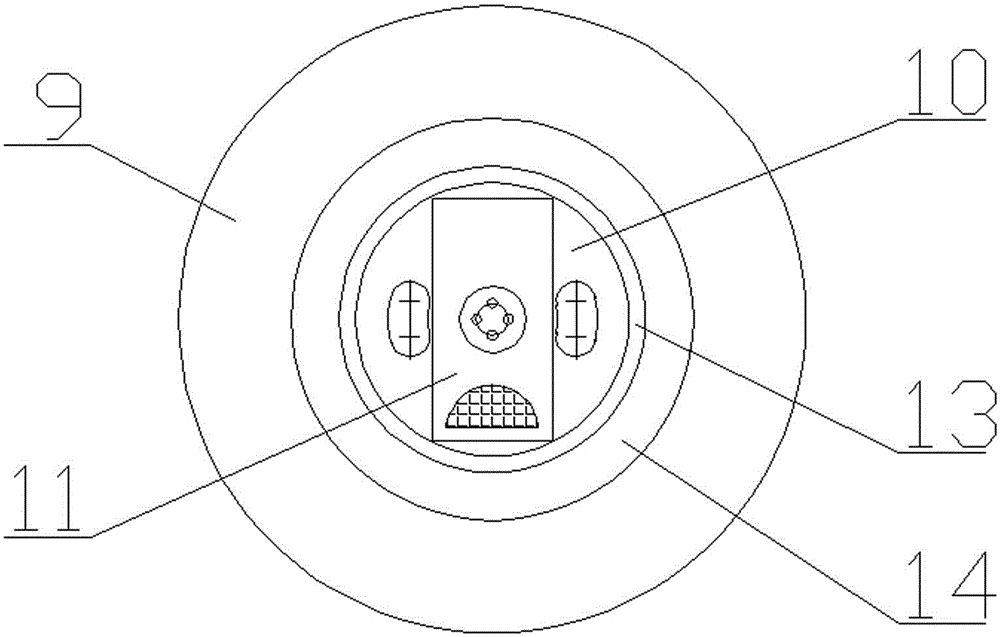

[0027] Figure 1-4 Shown: a Geo-level explosion-proof and combustion-proof cap for a power battery includes an upper cap 1, an explosion-proof membrane 4 with a wall 5, an orifice plate 10, a transition tab 11, an inner sealing ring 12, an outer sealing ring 9, and an upper cap 1 It is arranged on the upper end surface of the explosion-proof membrane 4 in a state of being bent and pressed inward by the wall body 5 and ultrasonically multi-point welded on the upper end surface of the upper cap 1. The upper cap 1 is evenly distributed with a plurality of air holes 2, and each air hole 2 is There is an overturning prestressed pressure relief buckle 3 connected to the upper cap 1, and the center of the lower end surface of the explosion-proof membrane 4 protrudes downwards to form a bun-packed raised structure 6, which is platform-shaped and multi-point laser spot w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com