Fast charge and discharge type power battery safety cap

A power battery and fast-discharging technology, which is applied in the direction of battery box/jacket, battery pack components, circuits, etc., can solve the problems of explosion-proof membranes that are easy to deform and rupture, easy to burn, and battery explosion, so as to improve safety explosion-proof performance and meet Fast charging and fast discharging, the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

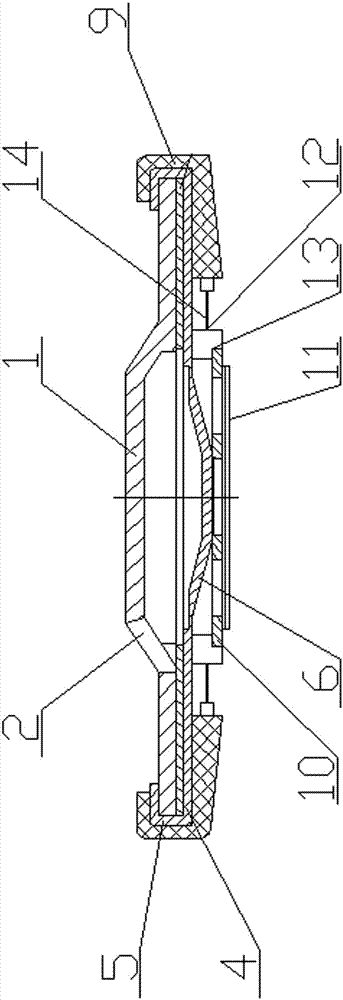

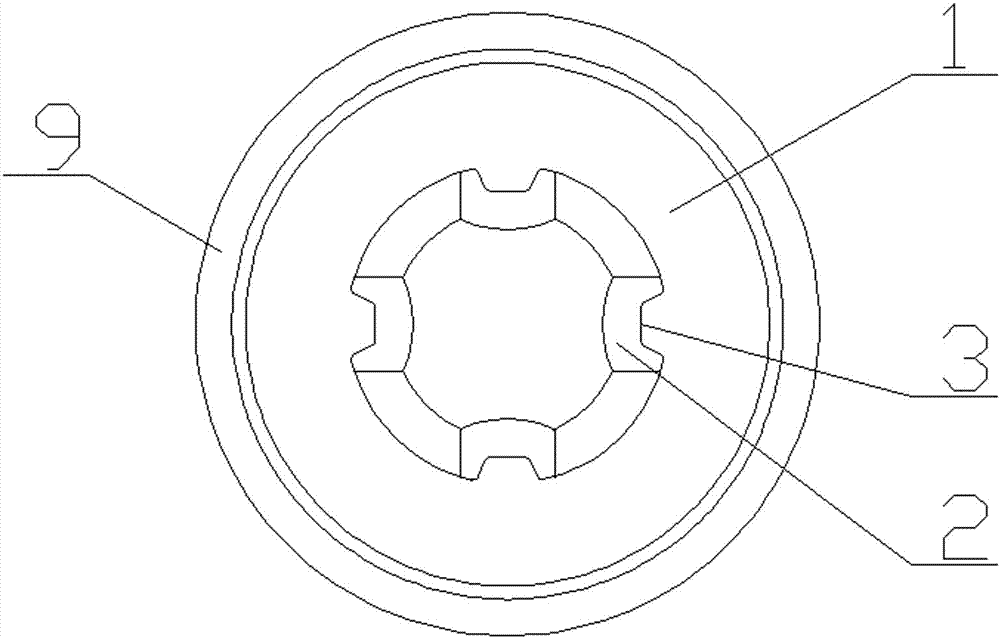

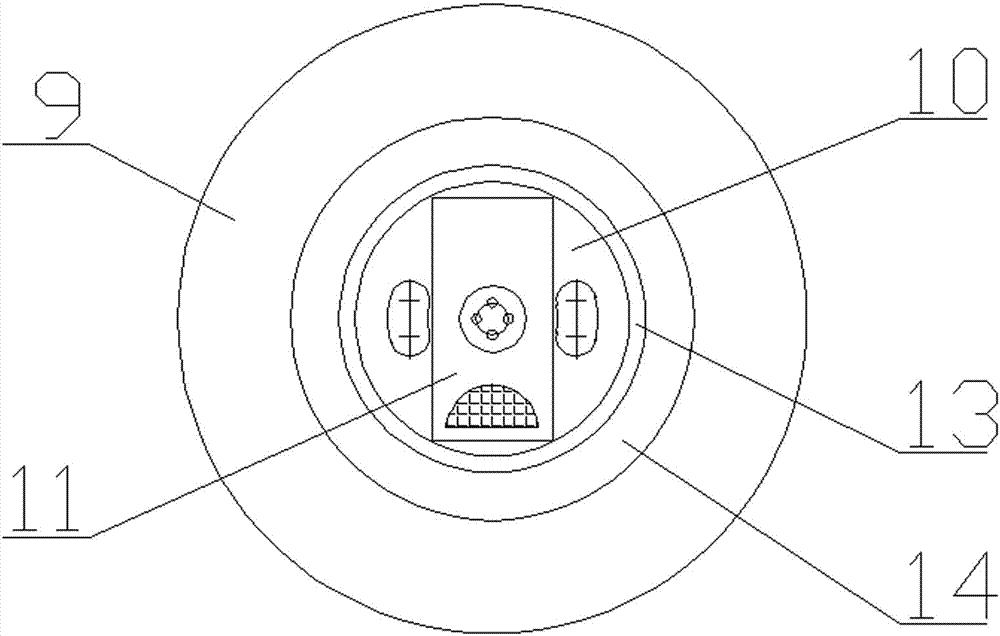

[0026] Figure 1-5 Shown: a fast-charging and fast-discharging power battery safety cap includes an upper cap 1, an explosion-proof membrane 4 with a wall 5, an orifice plate 10, a transition tab 11, an inner sealing ring 12 and an outer sealing ring 9, the upper cap 1 It is arranged on the upper end surface of the explosion-proof membrane 4 in a state of being bent and pressed inward by the wall body 5 and ultrasonically welded on the upper end surface of the upper cap 1 at multiple points. The upper cap 1 is evenly distributed with a plurality of air holes 2, and each air hole 2 There is an overturned pre-stressed pressure relief buckle 3 connected to the upper cap 1, the center of the lower end face of the explosion-proof membrane 4 is convex in the shape of a steamed bun-loading bulge structure 6, and the steamed bun-loading bulge structure 6 is a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com