Quick-charging battery safety cap

A rechargeable battery and cap technology, which is applied in the field of fast-charge battery safety caps, can solve the problems of explosion-proof membranes that are easily deformed and broken, easy to burn, and battery explosions, and achieve the effects of improving safety and explosion-proof performance, satisfying fast charging and fast discharging, and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

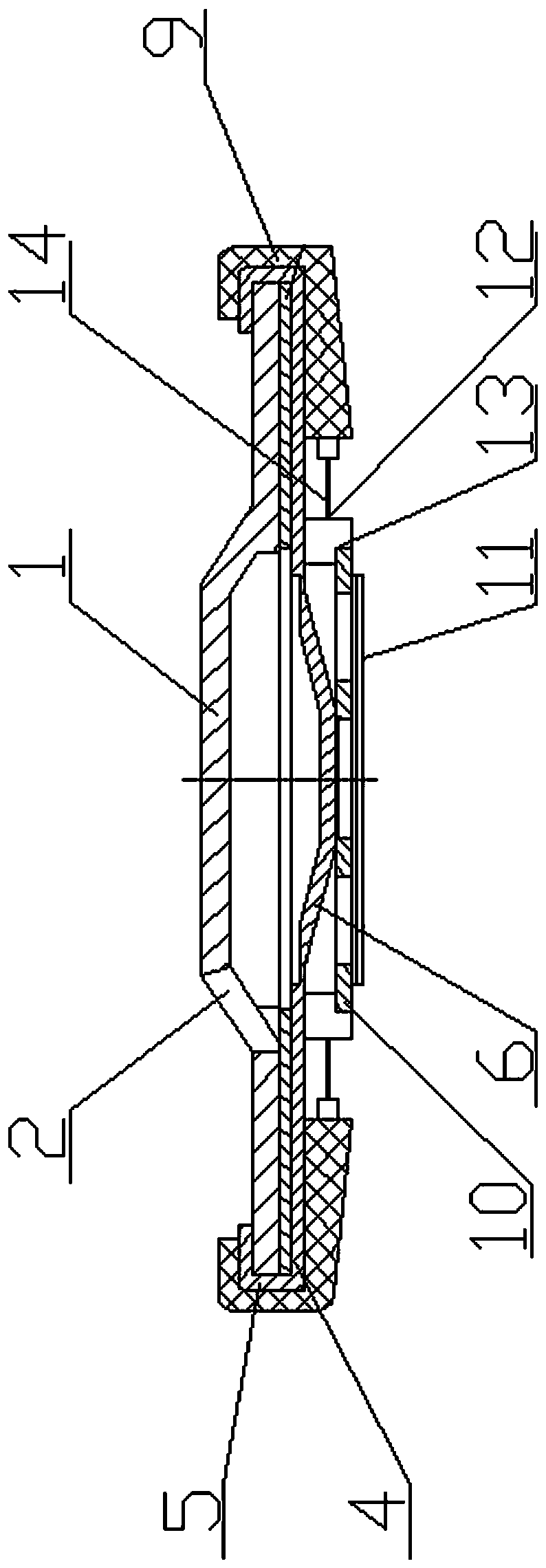

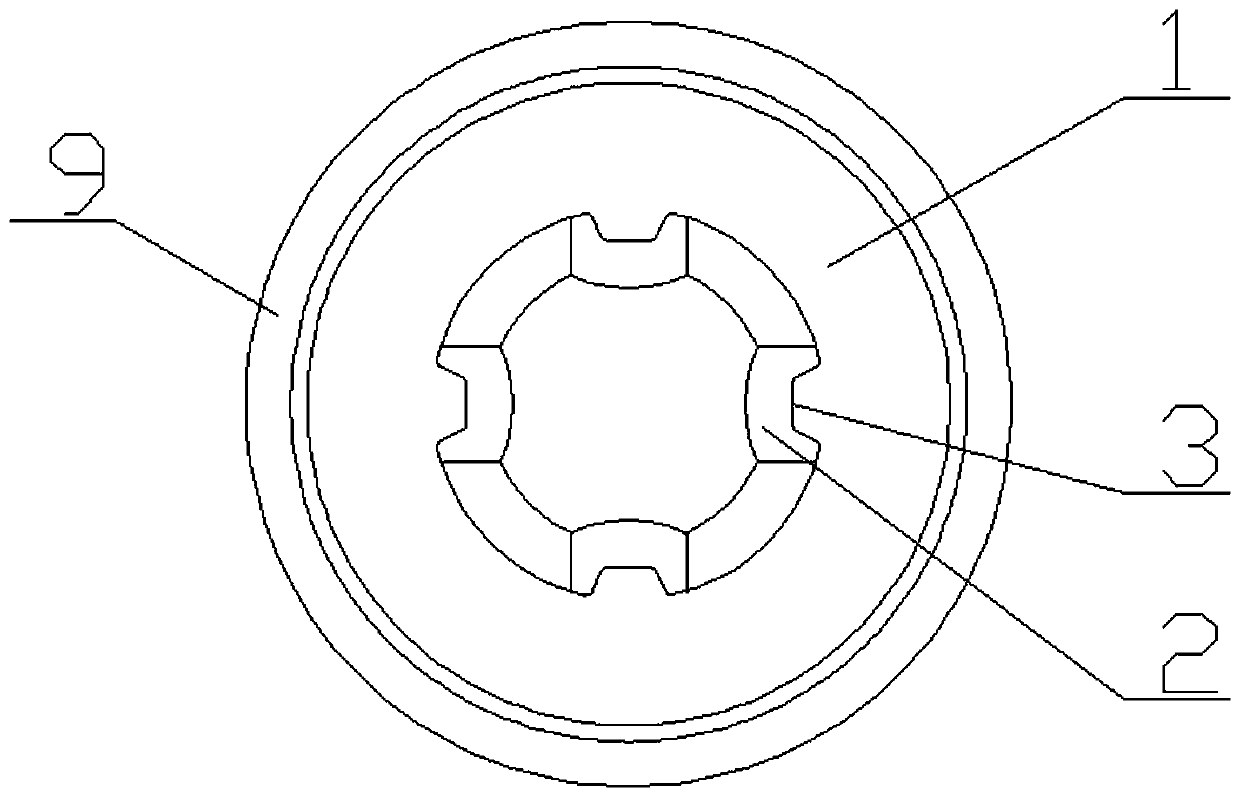

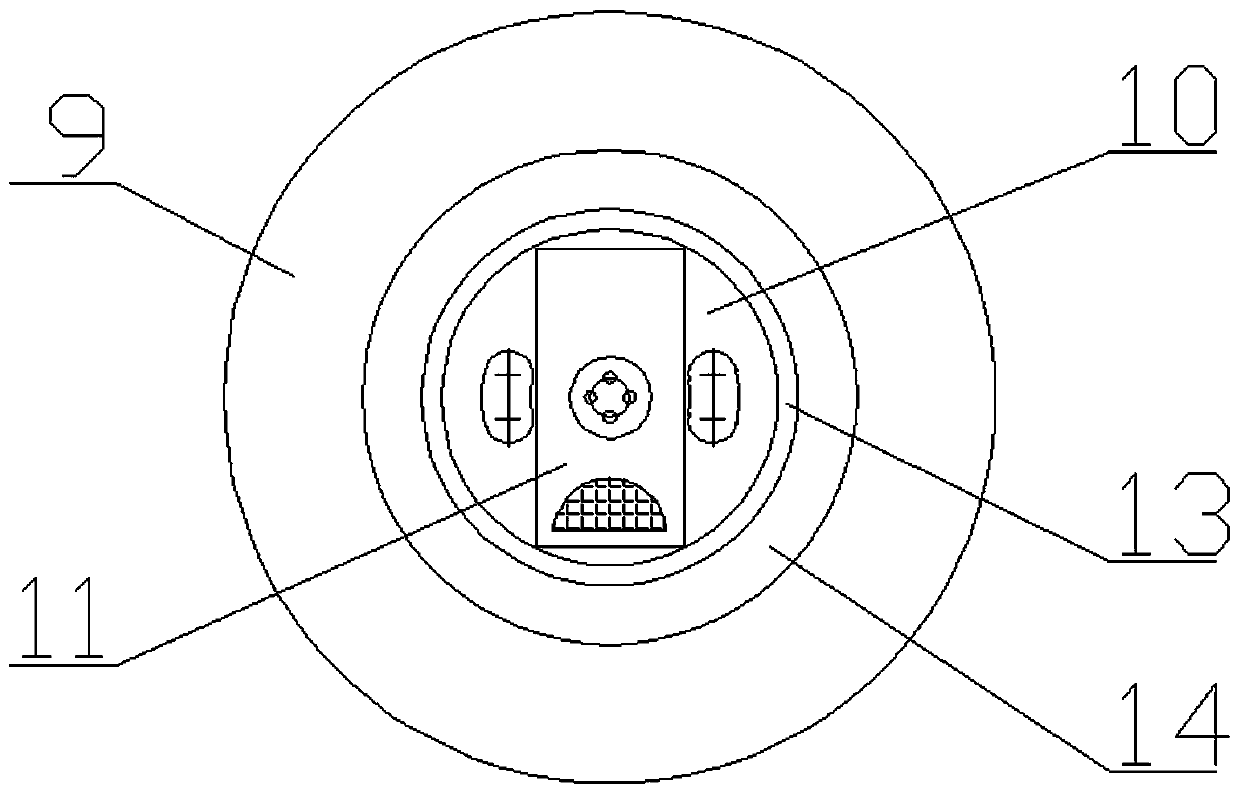

[0026] Figure 1-5 As shown: a fast charging battery safety cap includes an upper cap 1, an explosion-proof membrane 4 with a wall 5, an orifice plate 10, a transition tab 11, an inner sealing ring 12 and an outer sealing ring 9, and the upper cap 1 is arranged on the explosion-proof membrane 4. The upper end face is in a state of being bent and pressed inward by the wall body 5 and ultrasonically multi-point welded on the upper end face of the upper cap 1. The upper cap 1 is evenly distributed with a plurality of air holes 2, and each air hole 2 is equipped with a connection The reverse prestressed pressure relief button 3 on the upper cap 1, the center of the lower end surface of the explosion-proof membrane 4 protrudes downwards to form a raised structure 6 for the steamed buns, the raised structure 6 for the steamed buns is platform-shaped and multi-point laser spot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com