A kind of pcb board and its manufacturing method

A technology of PCB board and board body is applied in the field of PCB board and its manufacturing to achieve the effect of increasing the heat dissipation area, preventing instantaneous temperature rise, and increasing the thermal conductivity efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

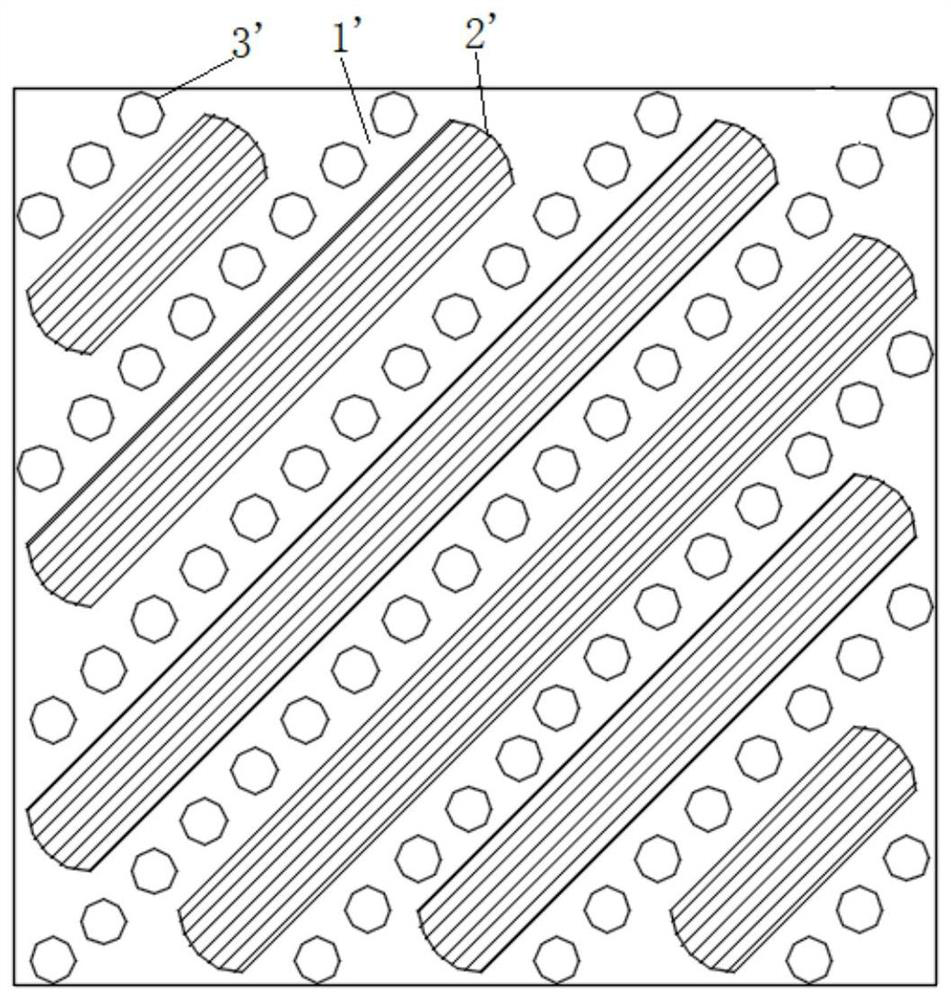

[0031] refer to figure 1 , a PCB board, including a PCB body, the PCB body has a TOP surface and a BOT surface opposite to the TOP surface, the components installed on the TOP surface are more than the BOT surface, and the BOT surface is mainly used for heat dissipation. The PCB The board body is provided with more than one via area 1', and the via area 1' is provided with a plurality of via holes 3', and the inner wall of each via hole 3' is covered with copper, wherein,

[0032] The TOP surface of the PCB body forms a first window by removing solder resist oil at the via area 1', so as to solder components after applying solder paste at the first window;

[0033] The BOT surface of the PCB body is covered with solder resist oil at the via hole area 1', and the BOT surface of the PCB body is formed by removing solder resist oil at a position adjacent to the via hole area 1' More than one second opening 2', so that the heat at the via area 1' can be conducted to the second op...

Embodiment 2

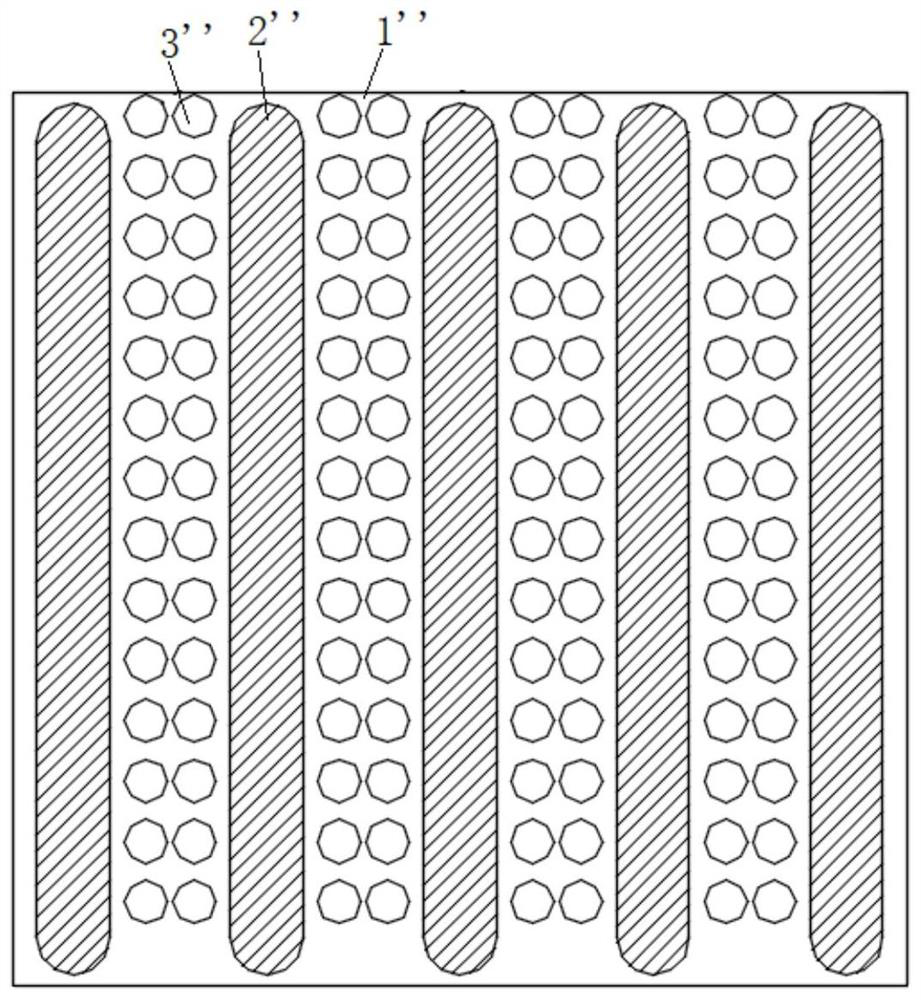

[0046] refer to figure 2 , a PCB board, including a PCB body, the PCB body has a TOP surface and a BOT surface opposite to the TOP surface, the components installed on the TOP surface are more than the BOT surface, and the BOT surface is mainly used for heat dissipation. The PCB The board body is provided with more than one via area 1", and the via area 1" is provided with a plurality of via holes 3", and the inner wall of each via hole 3" is covered with copper, wherein,

[0047] The TOP surface of the PCB body forms a first window by removing the solder resist oil at the via area 1", which is used for soldering components after applying solder paste at the first window;

[0048] The BOT surface of the PCB body is covered with solder resist oil at the via hole area 1", and the BOT surface of the PCB body is formed by removing solder resist oil at a position adjacent to the via hole area 1". More than one second opening 2", so that the heat at the via area 1" can be conducte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com