Vertical type electrothermal frying furnace

An electric heating fryer, vertical technology, applied in the utensils for frying things in oil, household utensils, applications, etc., can solve the problems of affecting environmental sanitation, rising oil temperature, affecting the human body, etc., to achieve beautiful appearance and reduce occupation. Space, the effect of easy cleaning of the oil tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings of the specification.

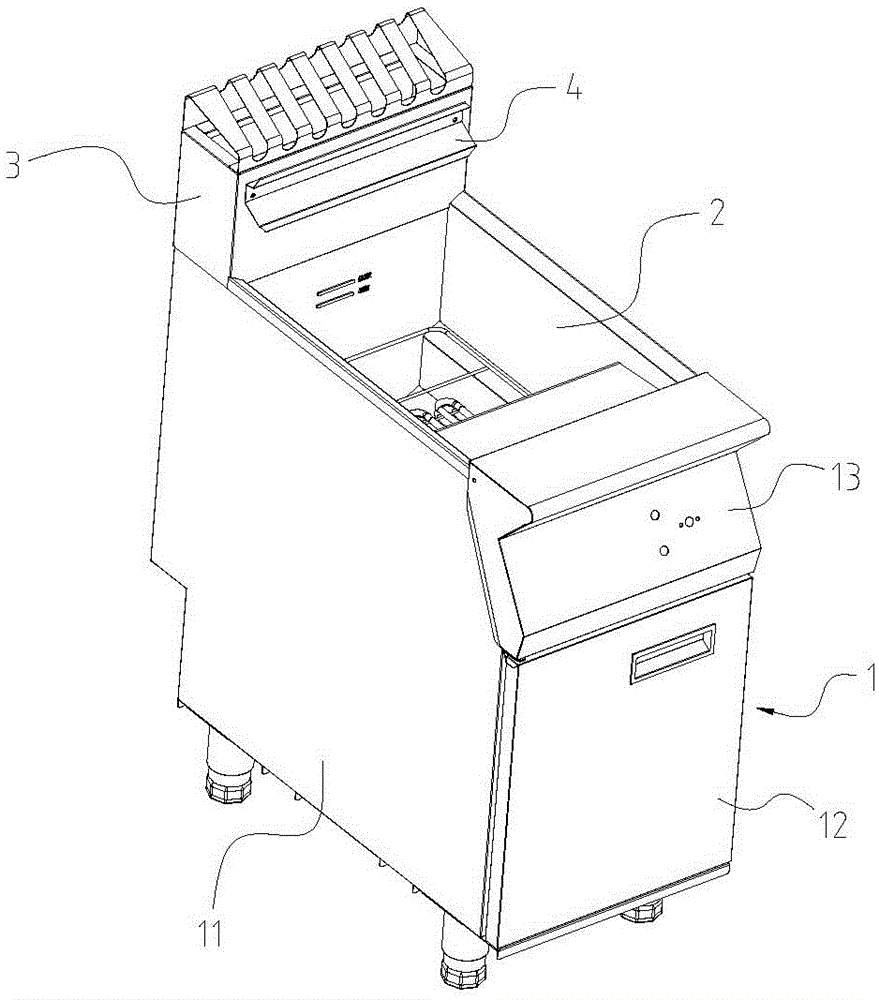

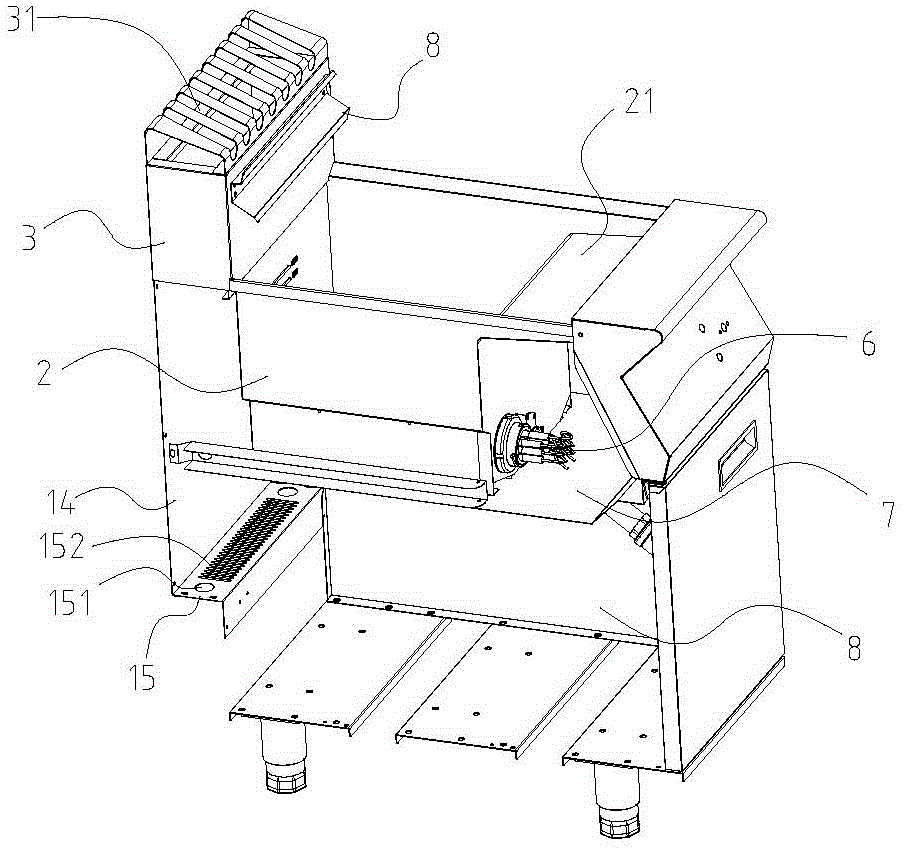

[0028] Such as image 3 As shown, a vertical electric fryer includes a shell 1, an oil tank 2, a heating assembly 8 and a control system.

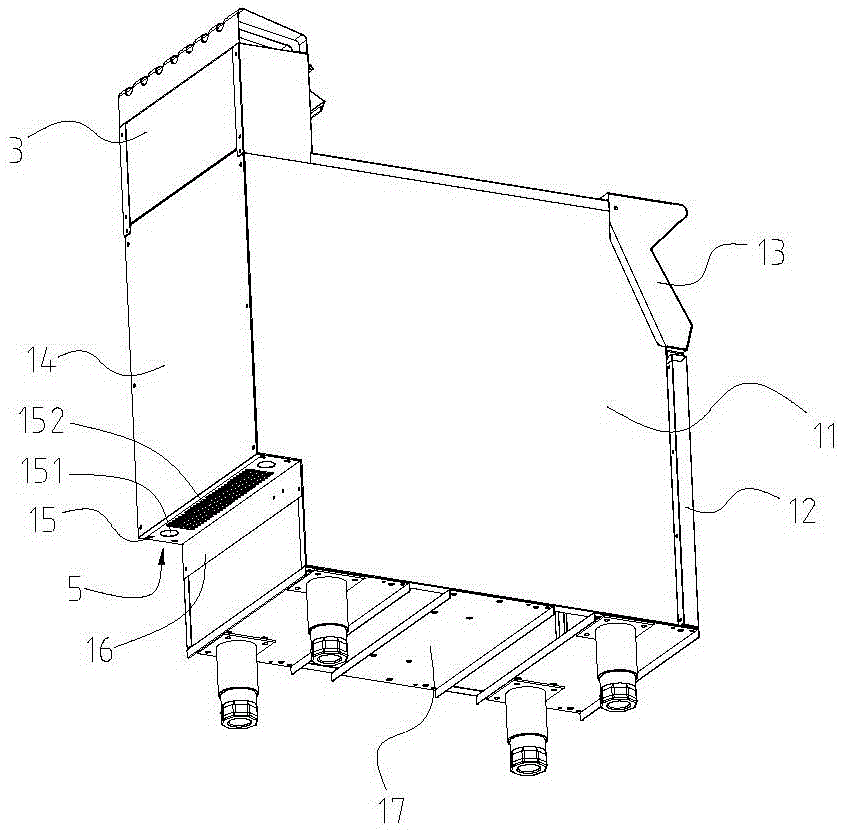

[0029] Such as Figure 1 to 4 As shown, the housing 1 includes a front sealing plate assembly, a rear sealing plate, a left side plate 11, a right side plate, and a bottom plate 17, and a front sealing plate assembly, a rear sealing plate, a left side plate 11, and a right side plate of the housing 1 The board and the bottom plate 17 enclose an accommodating cavity, and the accommodating cavity is divided into an upper accommodating cavity 7 and a lower accommodating cavity 8. The oil tank 2 is installed in the upper accommodating cavity 7 of the casing 1; the front sealing plate assembly includes a control panel 13 and a movable door panel 12 arranged below the control panel 13, and the movable door 12 can be opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com