powder mixing tank

A mixing tank and powder technology, applied in the direction of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of reduced stirring speed, uneven stirring, and decreased mixing quality, and achieve the effect of improving quality, delicate quality, and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

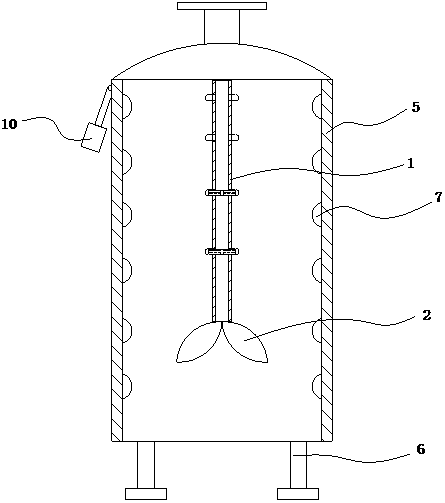

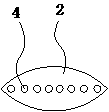

[0015] The present invention as Figure 1-3 As shown, it includes a stirring tank 5, a stirring shaft 1 and a stirring blade 2, the stirring shaft 1 is vertically arranged at the center of the stirring tank 5, the bottom of the stirring tank is provided with a foot 6, and the stirring blade 2 is arranged on the The lower end of the stirring shaft 1; the inner wall of the stirring tank 5 is uniformly provided with elastic protrusions 7 (which can be elastic rubber bodies), and the surface of the stirring tank is movable with a weight 10, which plays a role in moving the elastic protrusions. powder shake off;

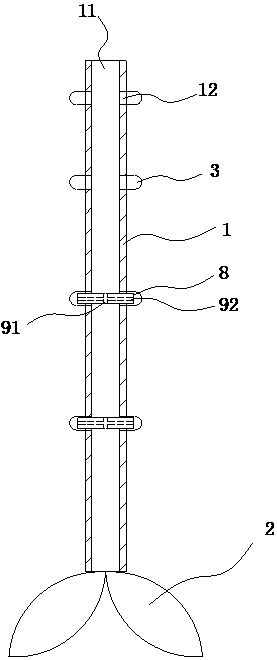

[0016] The stirring shaft 1 has a hollow accommodating chamber 11, the surface of the stirring shaft 1 is uniformly provided with a plurality of stretchable elastic bodies 3, and the side wall of the stirring shaft 1 is provided with through holes communicating with the elastic bodies 3 12. The upper end of the stirring shaft 1 is connected to an air source;

[0017] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com