Welding tooling and welding method for driving frame of construction elevator

A technology for construction lifts and welding tooling, applied in welding/welding/cutting items, welding equipment, auxiliary welding equipment, etc., can solve problems such as the inability to guarantee the size of the positioning parts, the inability to guarantee the parallelism of the main channel steel, and the inability to meet the accuracy requirements. , to achieve the effect of convenient and quick loading and unloading, improve work efficiency and labor intensity, and reduce welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

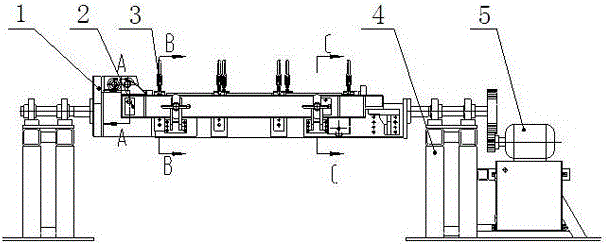

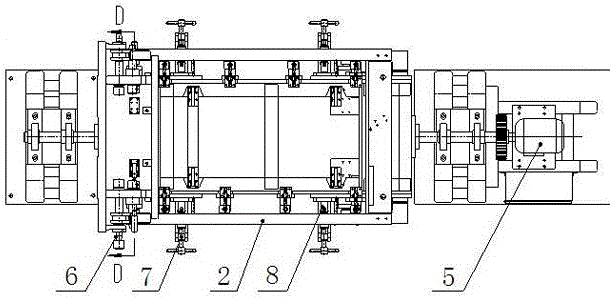

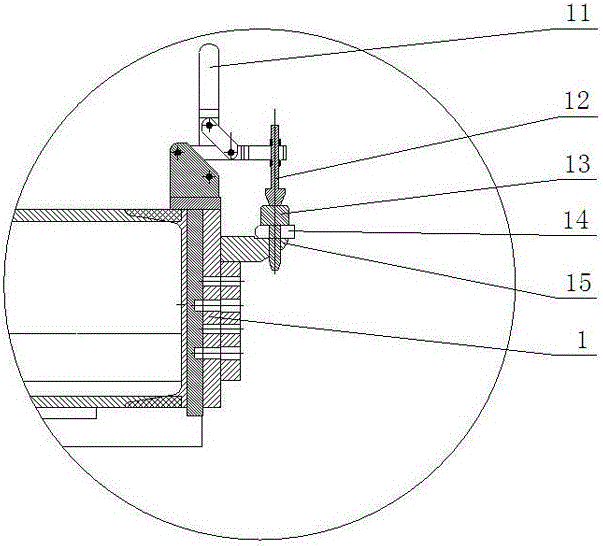

[0032] This embodiment provides a welding tool for the drive frame of a construction hoist, such as figure 1 with figure 2 As shown, it includes a support 4 and a welding platform 1. The welding platform 1 is a tooling support device welded by profiles including channel steel and square pipes and undergoes aging treatment; the central axis of the welding platform 1 cooperates with the bearing on the support 4, The welding platform 1 can be turned around the central axis; the support 4 is provided with a turning drive mechanism 5 that is engaged with the central axis of the welding platform 1 through gears; Roller positioning assembly, drive plate mounting plate positioning assembly 3, main channel internal back spacing positioning and pre-deformation device 8, channel steel clamping device 7, wherein the ear plate positioning assembly 6 is a part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com