Shearing and recycling device for waste liquid gas storage tank

A technology for liquefied gas tanks and recovery equipment, which is applied in the direction of shearing equipment, shearing devices, metal processing equipment, etc., can solve the problem of no recovery and treatment of liquefied gas tanks, achieve high automation, high work efficiency, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

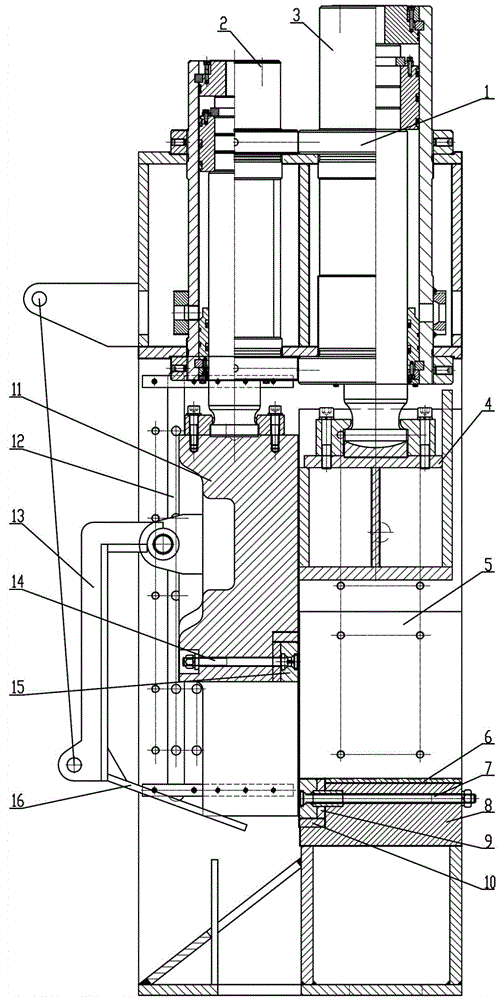

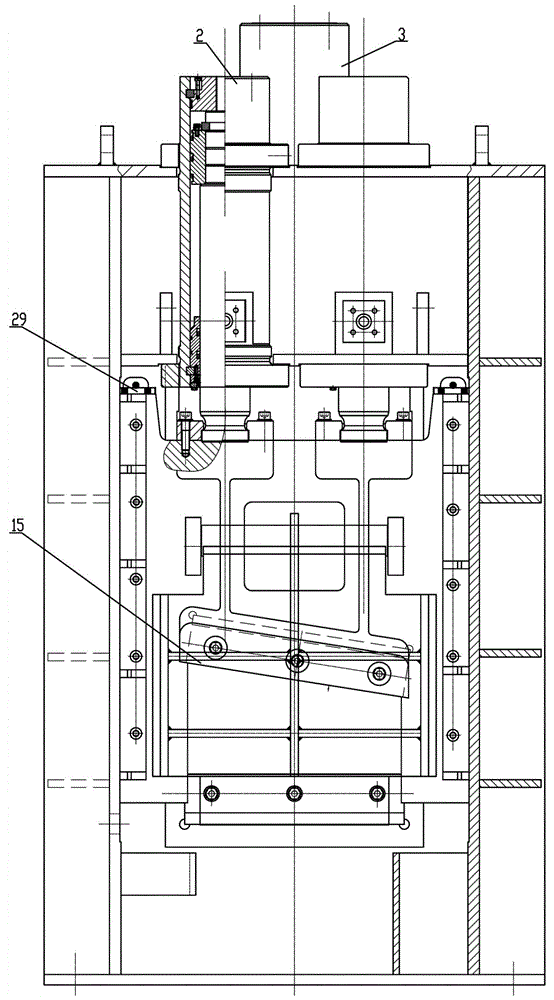

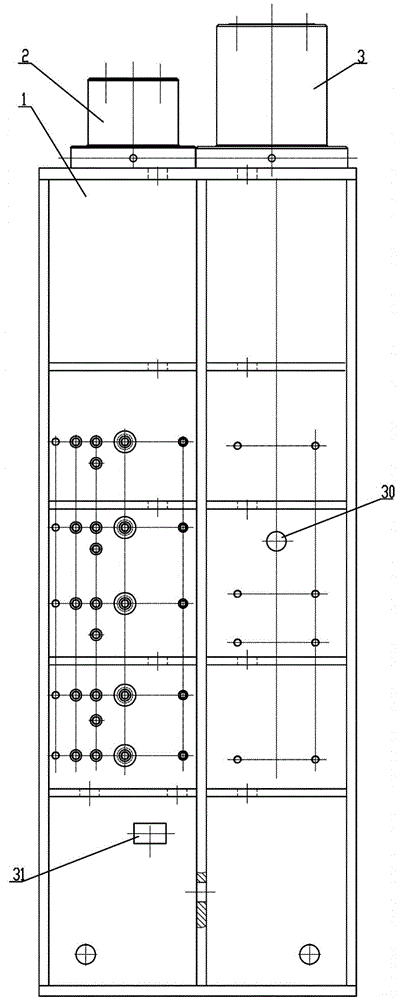

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] join Figure 1-5 , waste liquefied gas tank shear recovery equipment, which includes a main body 1, the top of the main body 1 is vertically installed with a shear cylinder 2 and a pressing cylinder 3, and a pressing head 4 is installed at the bottom of the piston rod of the pressing cylinder 3, The pressing head 4 cooperates with the bottom guard plate 6 to realize the pressing operation. The bottom of the piston rod of the shearing cylinder 2 is fixedly equipped with a scissor slide 11. The scissor slide 11 and the guide rail plate 12 form a sliding fit. The bottom of the blade is tightly fixed with a blade 15 by the cutter head bolt 14, and the blade 15 cooperates with the vertical knife pad 9 to complete the shearing operation. The main body 1 is composed of welded structural parts to support other components such as the shearing cylinder 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com