Vertical shot blasting processing machine system for pipe wall surface processing and shot blasting processing method

A technology of surface treatment and treatment method, which is applied in the field of steel pipe treatment, can solve the problems of long time for rust removal, bulky volume, low efficiency, etc., and achieve uniform metallic luster, simple system structure and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

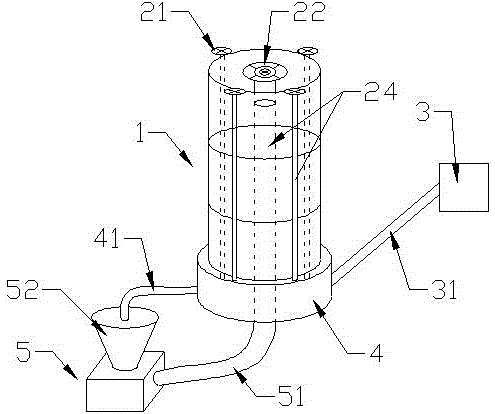

[0042] Example 1, such as figure 1 As shown, the vertical shot blasting treatment machine system for pipe wall surface treatment includes a shot blasting chamber 1, which is a vertically placed cylindrical space structure, which can be specifically made of tubular materials or pipes on the ground or underground. A hollow cylindrical structure surrounded by building materials.

[0043] The shot blasting chamber 1 can be cylindrical or prismatic. In this embodiment, a cylindrical shot blasting chamber is taken as an example for illustration.

[0044] The axial direction of the shot blasting chamber 1 is arranged along the vertical direction, and the axial height of the shot blasting chamber 1 is greater than the diameter of the bottom surface of the shot blasting chamber 1 .

[0045] Below the shot blasting chamber 1, there is a sand shot recovery device 4, which is composed of at least two layers of screens with different apertures, and is used to filter the sundries in the sa...

Embodiment 2

[0060] Embodiment 2, a kind of shot blasting treatment method that is used for pipe wall surface treatment, adopts the vertical shot blasting treatment machine system described in embodiment 1, and described treatment method comprises the following steps:

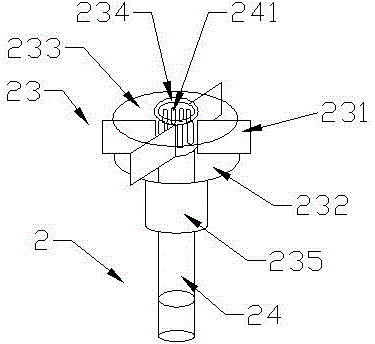

[0061] 1) Shot feeding step: the sand shot pumping device 5 works to transport the sand shot from the bottom of the sand supply pipe 24 to the shot blasting head main body 23 on the top of the sand supply pipe 24 .

[0062] 2) Shot blasting step: when the sand shot reaches the top of the sand supply pipe 24 along the vertical direction of the bottom of the sand supply pipe 24, it enters the shot blasting head blade 231 of the shot blasting head main body 23 through the sand dividing hole 241, and passes through the rotating blasting head. The ball head blade 231 is thrown out in the horizontal direction after being accelerated.

[0063] 3) Recovery step: the sand shot falls into the sand shot recovery device 4 under the sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap