Low center of gravity trailer with lift mechanism

A lifting mechanism and low-center-of-gravity technology, applied to motor vehicles, vehicles carrying parallel loads, transportation and packaging, etc., can solve problems such as high center of gravity and poor transportation mobility, and achieve lower transportation center of gravity, improved mobility, and stable transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

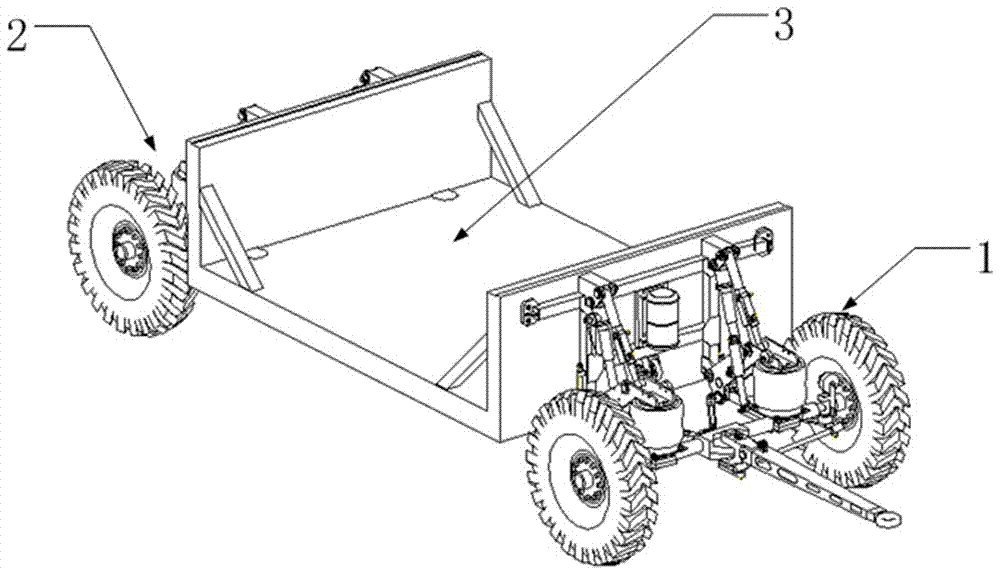

[0037] See figure 1 , The low-gravity trailer with a lifting mechanism includes a front towed steering wheel set 1, a rear towed walking wheel set 2 and a towed pallet 3.

[0038] The longitudinal section of the trailer pallet 3 is U-shaped, one of which is the front vertical plate, which is connected to the front towed steering wheel set 1 through the front lifting mechanism; the other vertical plate is the rear vertical plate. The rear vertical plate is connected to the rear towing walking wheel group 2 through the rear lifting mechanism.

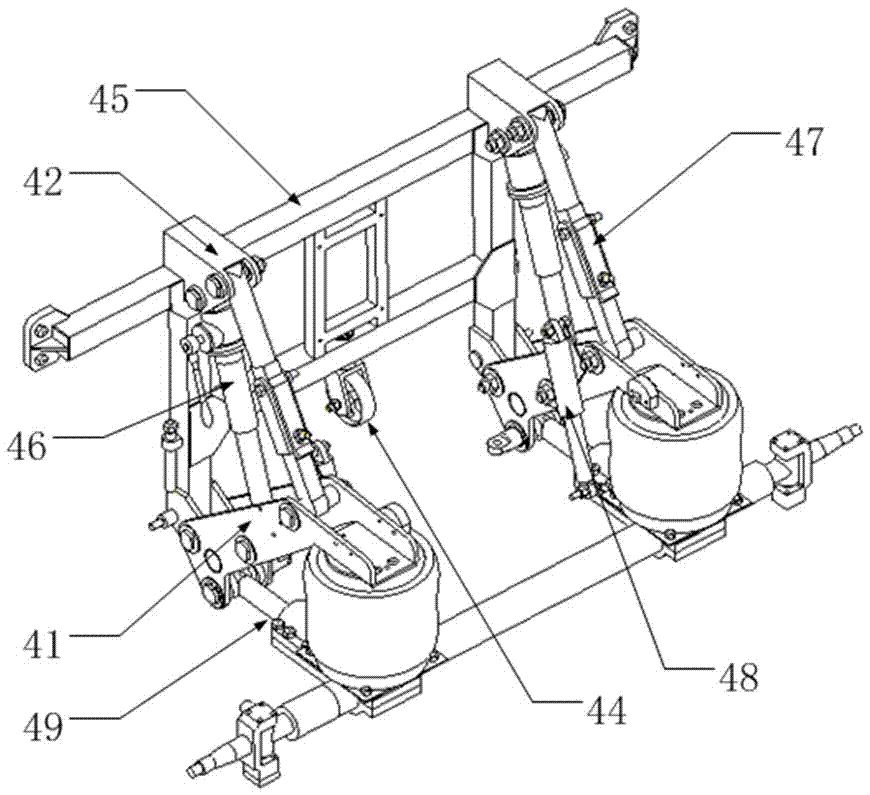

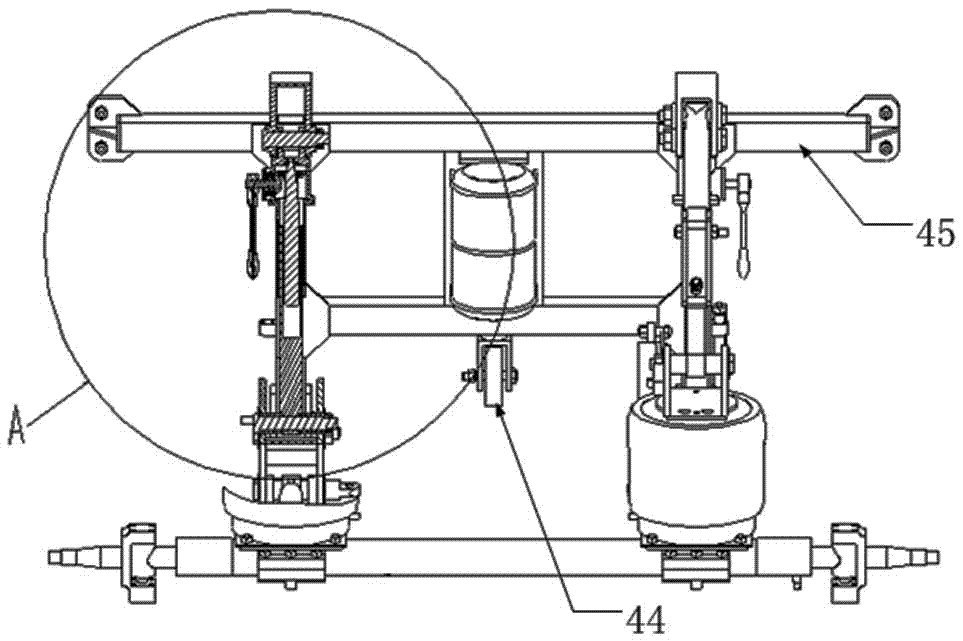

[0039] See Figure 7 with Picture 9 , The structure of the front lifting mechanism and the rear lifting mechanism are the same to realize the synchronous ascending or descending of the towed pallet 3.

[0040] In the descending state, the bottom surface of the towing pallet 3 is in contact with the ground, and in the rising state, the distance between the bottom surface of the towing pallet 3 and the ground is less than 400 mm.

[0041] See fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com