Express delivery point lifting type storage rack with automatic goods storage function and operation method of express delivery point lifting type storage rack

A lifting and cargo technology, applied in the field of shelves, can solve the problem of high labor intensity, and achieve the effects of reducing labor intensity, reliable and effective control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

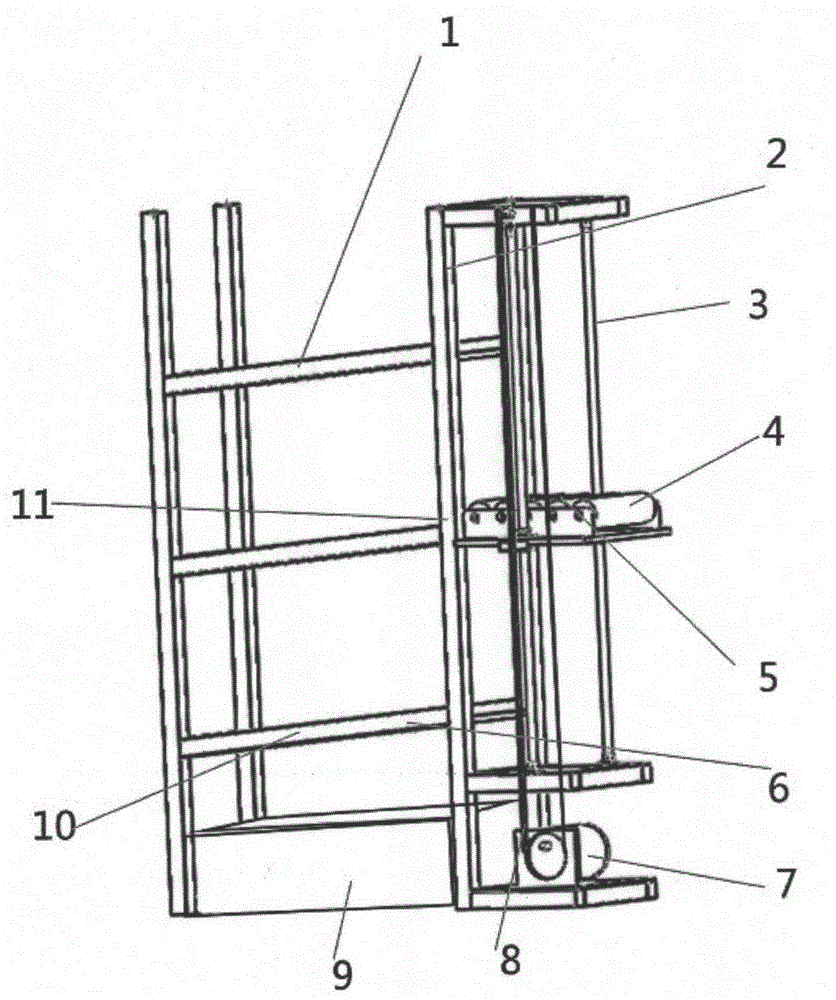

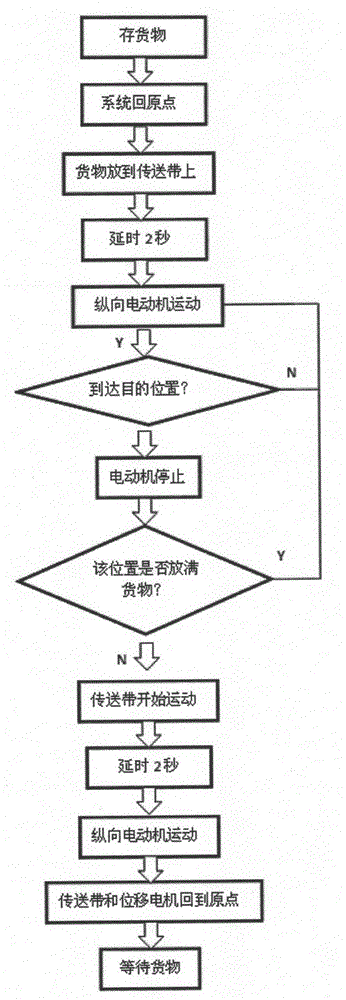

[0024] The present invention is a kind of express delivery point lifting shelf with automatic storage of goods, such as Figure 1-2 As shown, it includes a support platform provided with moving components, and the support platform includes a plurality of transverse support frames 1 (ie at least two transverse support frames 1 ) and a longitudinal support frame 2 connecting the transverse support frames 1 . A position sensor 6 is installed on the horizontal support frame 1 adopted by the present invention, so as to detect whether the horizontal shelf reaches the maximum capacity of the goods in a safe state. In order to prevent the goods from being placed on the shelf between the conveyor belt 5 and the self-weight conveying roller 10, the position sensor 6 is set at a certain distance from the conveyor belt 5. In order to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com