Rail plate locking seat of magnetic levitation rail

A technology of magnetic levitation and locking seat, applied in the directions of track, laying track, track maintenance, etc., can solve the problems of complex structure of the magnetic levitation rail plate locking seat, inconvenient assembly and disassembly, etc., and achieves simple structure, convenient assembly and disassembly, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

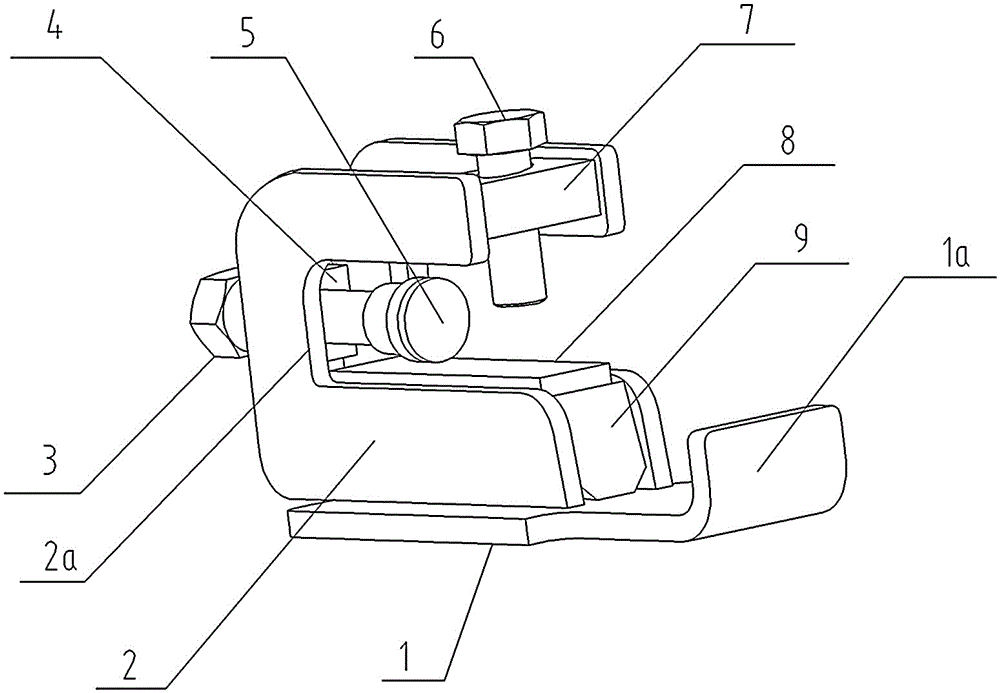

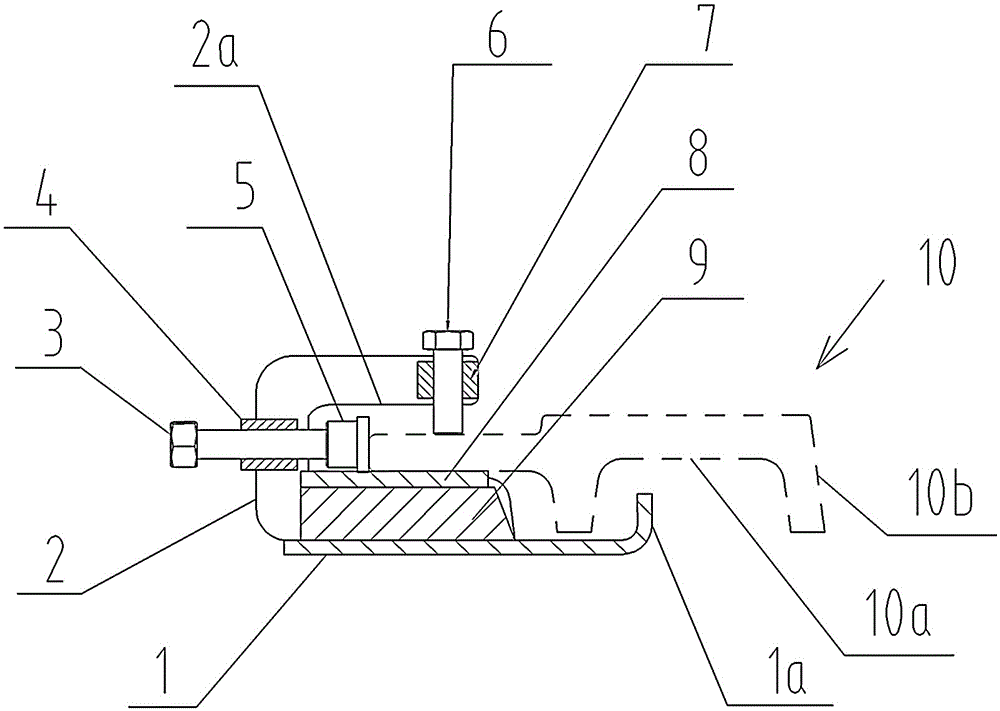

[0015] like figure 1 , figure 2 As shown, the rail plate locking seat of a magnetic levitation track provided by the present invention includes a base plate 1, a pair of vertical plates 2 are arranged on the base plate, a support block 9 is provided on the base plate between the vertical plates, and a support block 9 is provided with The backing plate 8 is respectively provided with an opening groove 2a matching with the F-shaped rail plate 10 on one side of the corresponding vertical plate 2, and one side of the F-shaped rail plate 10 is placed in the opening groove 2a, and its bottom is slidably matched with the top of the backing plate 8, A section of the base plate 1 is a vertically upward bending section 1a, which is placed in the track groove 10a of the F-shaped rail plate and forms a limiting fit with the two wings 10b of the F-shaped rail plate; The first connecting plate 7 is arranged between the corresponding vertical plates 2, and the first connecting plate is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com