Round-corner lock floor and machining method thereof

A technology of rounded corners and floors, which is applied in the direction of floors, buildings, building structures, etc. It can solve the problems that the area and angle of chamfers cannot reach the ideal index, and achieve the effect of beautiful gaps, reduced processing procedures, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

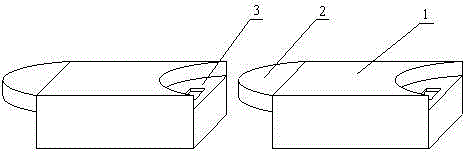

[0022] Example 1: A kind of rounded lock floor, including board body 1, such as figure 1 Shown:

[0023] The upper part of the adjacent two sides of the plate body 1 is horizontally provided with an outwardly protruding rounded tenon 2, and the corresponding other two sides are provided with an inwardly recessed rounded tenon groove 3 matching the rounded tenon 2. The tenon 2 is connected with the rounded tenon groove 3 of another floor by interference fit; the lower surface of the rounded tenon 2 is provided with a positioning bump, and the corresponding position in the rounded tenon groove is provided with a positioning groove matching the positioning bump.

[0024] The maximum width of the rounded tenon 3 is consistent with the width of the board body 1, and the length protruding from the board body 1 is 1 / 4 of the length of the board body, and the thickness of the rounded tenon 3 is 1 / 3 of the thickness of the board body.

[0025] A method for processing a rounded lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com