Test method for impregnation performance of glass fiber in resin

A technology of glass fiber and testing method, which is applied in the field of testing the impregnation performance of glass fiber in resin, which can solve the problems of partial subjectivity, no quantitative index, inability to evaluate the impregnation performance of glass fiber accurately, effectively and objectively, and achieve accurate Effect of impregnation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

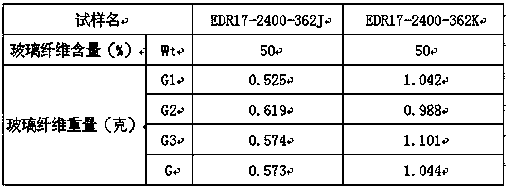

[0037] Raw material: glass fiber: Jushi Group Co., Ltd., EDR17-2400-362J; Jushi Group Co., Ltd., EDR17-2400-362K; thermoplastic: polypropylene (PP), Sinopec, F401; glass fiber content, 50%;

[0038] Test conditions: temperature is 23°C, relative humidity is 50%.

[0039] Test steps:

[0040] (1) Put two groups of glass fiber reinforced PP pellets produced by the LFT process to be tested, with 50% glass fiber content, into a vacuum drying oven, set the temperature at 90°C, and dry for 16 hours;

[0041] (2) Place the pellets produced by the LFT process in an environment with a temperature of 23°C and a relative humidity of 50%, and cool the pellets for 30 minutes so that the pellets are at the same temperature as the environment;

[0042](3) In an environment with a temperature of 23°C and a relative humidity of 50%, use an electronic balance (accurate to 0.001g) to produce pellets by two groups of LFT processes, each group has three parts, each part is 80 grams, and one part ...

Embodiment 2

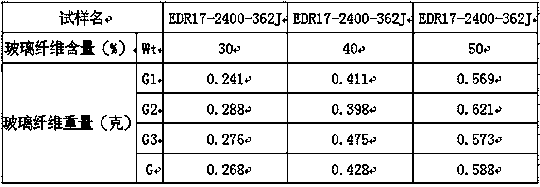

[0050] Raw material: glass fiber: Jushi Group Co., Ltd., EDR17-2400-362J; thermoplastic: polypropylene (PP), Sinopec, F401: glass fiber content is 30%, 40%, 50%;

[0051] Test conditions: temperature is 23°C, relative humidity is 50%.

[0052] Test steps:

[0053] (1) Put the three groups of glass fiber reinforced PP pellets produced by the LFT process to be tested, with 50% glass fiber content, into a vacuum drying oven, set the temperature at 90°C, and dry for 16 hours;

[0054] (2) Place the pellets produced by the LFT process in an environment with a temperature of 23°C and a relative humidity of 50%, and cool the pellets for 30 minutes so that the pellets are at the same temperature as the environment;

[0055] (3) In an environment with a temperature of 23°C and a relative humidity of 50%, use an electronic balance (accurate to 0.001g) to produce pellets by three groups of LFT technology, each group has three parts, each part is 80 grams, and one part is weighed Put th...

Embodiment 3

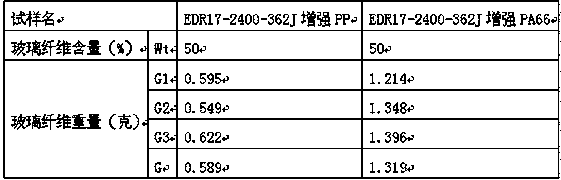

[0063] Raw materials: glass fiber: Jushi Group Co., Ltd., EDR17-2400-362J; thermoplastics: polypropylene (PP), Sinopec, F401; nylon 66 (PA66), DuPont, 101L: glass fiber content 50%;

[0064] Test conditions: temperature is 23°C, relative humidity is 50%.

[0065] Test steps:

[0066] (1) Put a group of glass fiber-reinforced PP pellets and a group of glass fiber-reinforced PA66, 50% glass fiber content, produced by the LFT process to be tested into a vacuum drying oven, set the temperature at 90°C, and the time is 16 hours , for drying treatment;

[0067] (2) Place the pellets produced by the LFT process in an environment with a temperature of 23°C and a relative humidity of 50%, and cool the pellets for 30 minutes so that the pellets are at the same temperature as the environment;

[0068] (3) In an environment with a temperature of 23°C and a relative humidity of 50%, use an electronic balance (accurate to 0.001g) to produce pellets by two groups of LFT processes, each gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com