Micro heat thermal method for quantitative evaluation on thermal stability of double-base propellant

A double-base propellant and micro-calorific heat technology, which is applied in the direction of material thermal development, can solve the problems of lack of criteria, inability to perform quantitative evaluation, poor operability and other problems in the thermal stability of double-base propellants, and achieve reliable experimental results High reliability, strong method practicability, and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

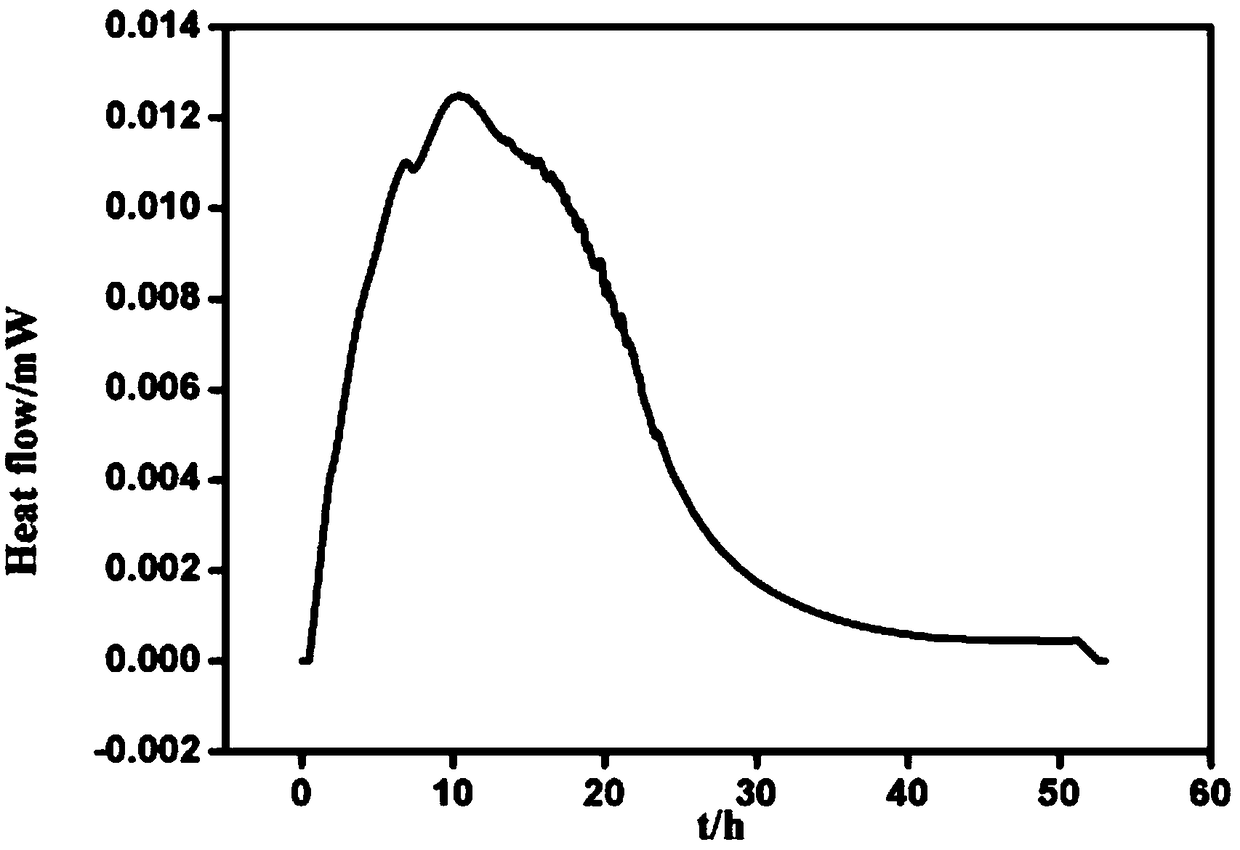

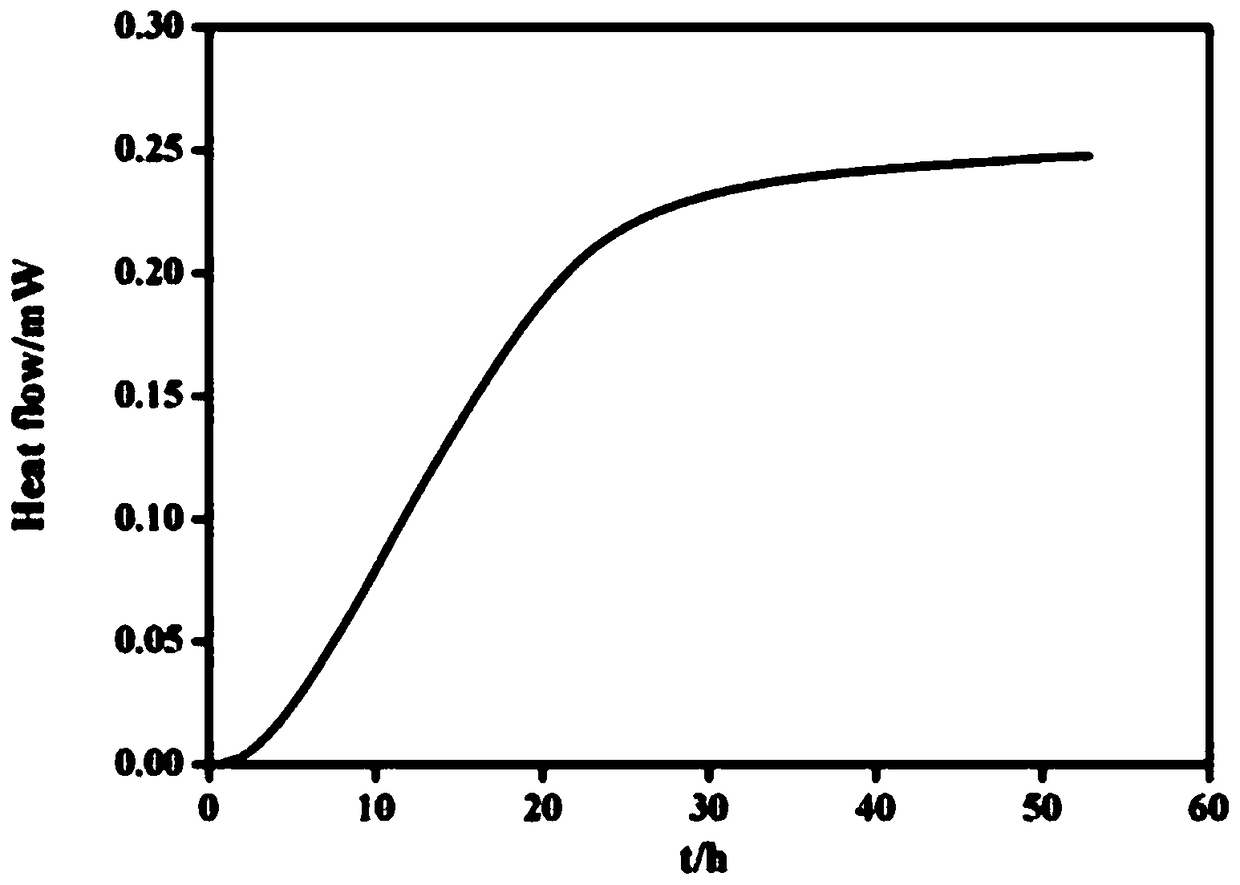

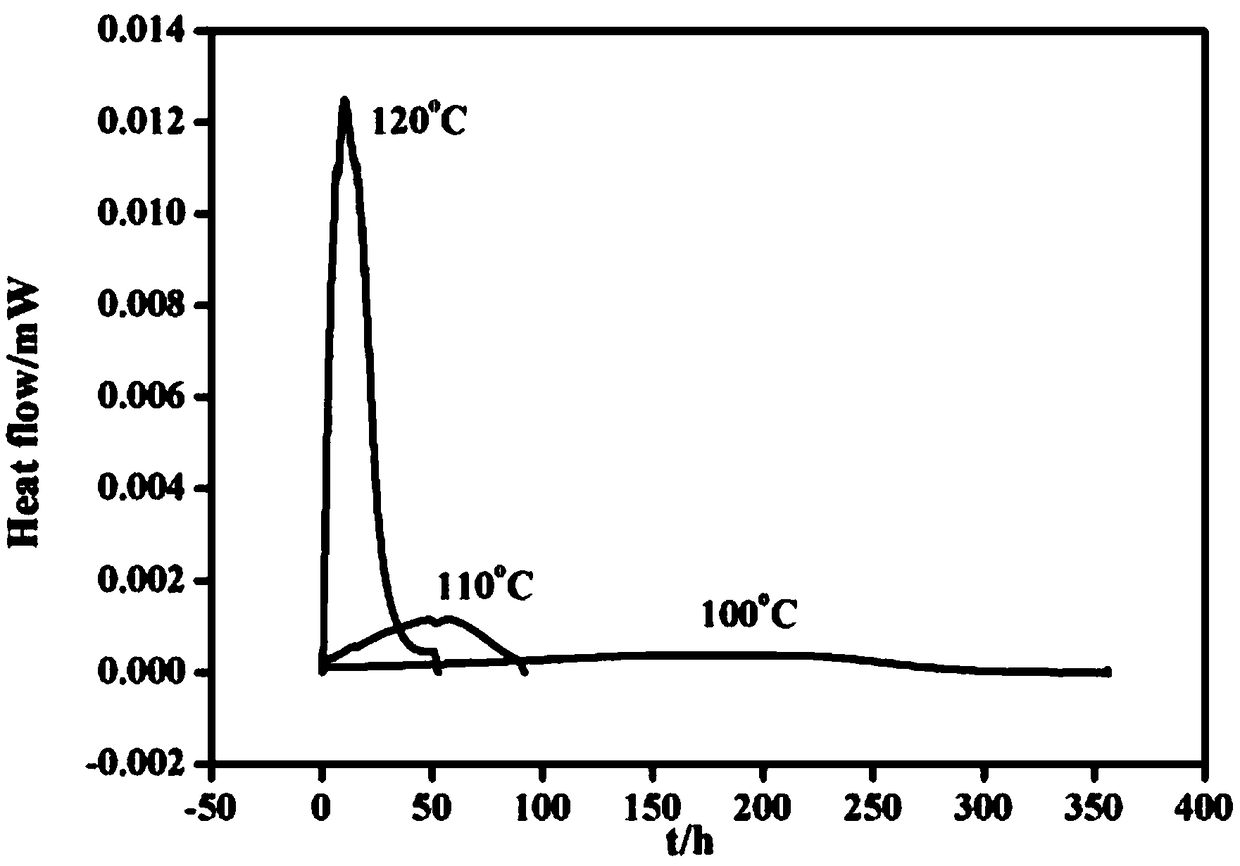

Embodiment 1

[0059] The micro-calorimetric method of the present invention quantitatively evaluates the thermal stability of double-base propellants, and is characterized in that the method does not require any complicated and dangerous sample pretreatment process, and uses a micro-calorimeter to track the dynamics of the decomposition and heat generation of double-base propellants Real-time change and its change law, obtain the correlation between the critical characteristics of accelerated decomposition and the decomposition process, select the inflection point of decomposition acceleration as the critical criterion, and establish the thermal stability criterion of calorimetry; The equivalence relationship forms a new method for evaluating the thermal stability of double-base propellants by microcalorimetry. Then, a single-temperature isothermal microcalorimetry experiment was carried out to track the experimental time when the heat of decomposition of the double-base propellant reached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com