Defect measurement method, defect measurement device and inspection probe

A measurement method and defect technology, applied in the field of inspection probes, can solve problems such as quantitatively measuring the depth of defects, and achieve the effect of rapid quantitative evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this specification, a magnetic member means a member made of a magnetic body, and examples thereof include cables, wires, plate-like members, various structures, and the like made of a magnetic body. Moreover, as a defect of a magnetic body member, the defect of a thin-walled shape (henceforth called a thin-walled thing), the defect of a crack shape, etc. are mentioned. In addition, the thinning of the wall thickness refers to a phenomenon in which the thickness is thinned due to mechanical wear, chemical corrosion, and the like.

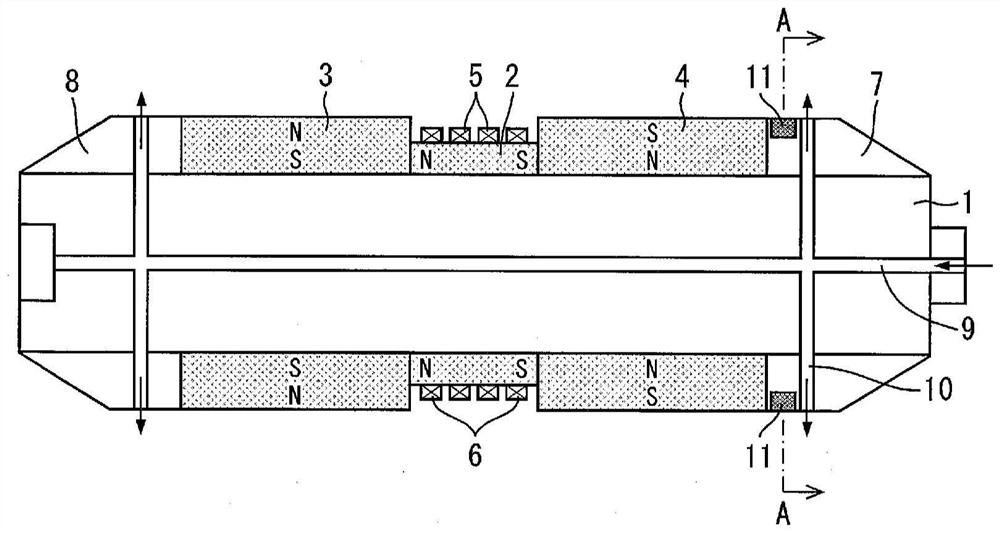

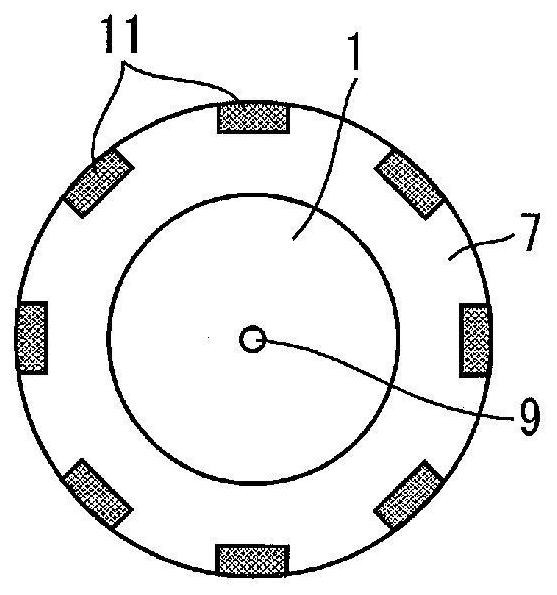

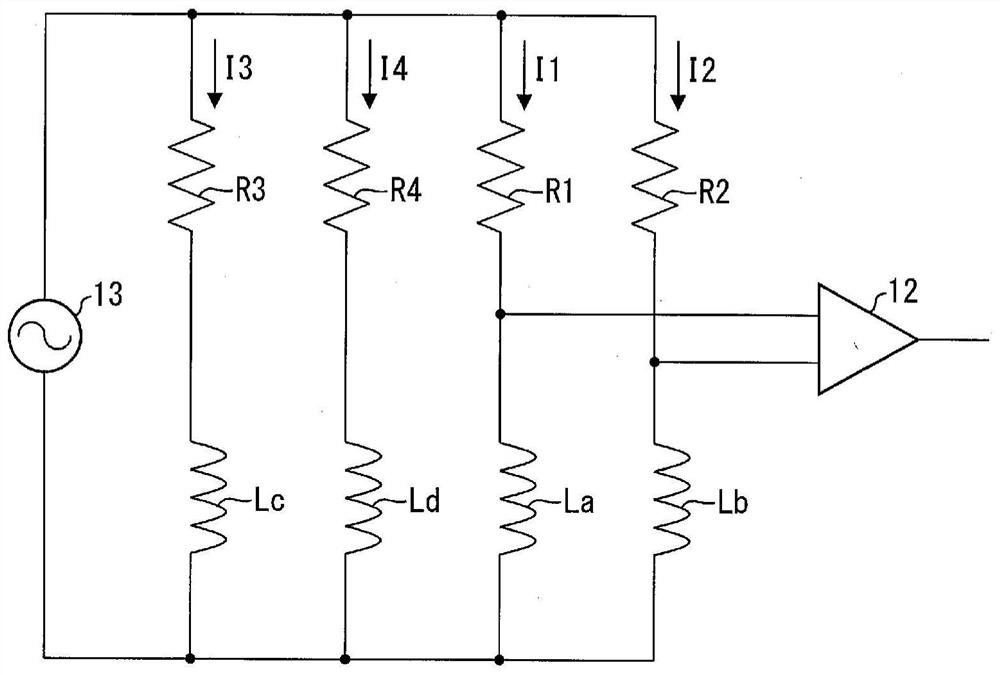

[0035] One embodiment of the present invention will be described. In this embodiment, an example in which a magnetic tube is used as an inspection object as a magnetic member, a Hall element is used as a magnetic sensor, and an excitation / detection coil is used as an eddy current flaw detection sensor is described to inspect the thinning of the wall. , but the application object of the present invention is neither limited to magnetic tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com