Method for testing methylene blue value of fine aggregate

A technology of methylene blue value and test method, which is applied in measurement devices, analysis materials, material analysis by optical means, etc., can solve the problem of low toxicity, avoid skin and eye contact, low test result accuracy, and cumbersome test operation process. and other problems, to achieve the effect of significant differentiation, reduction of errors, and accurate and reliable test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

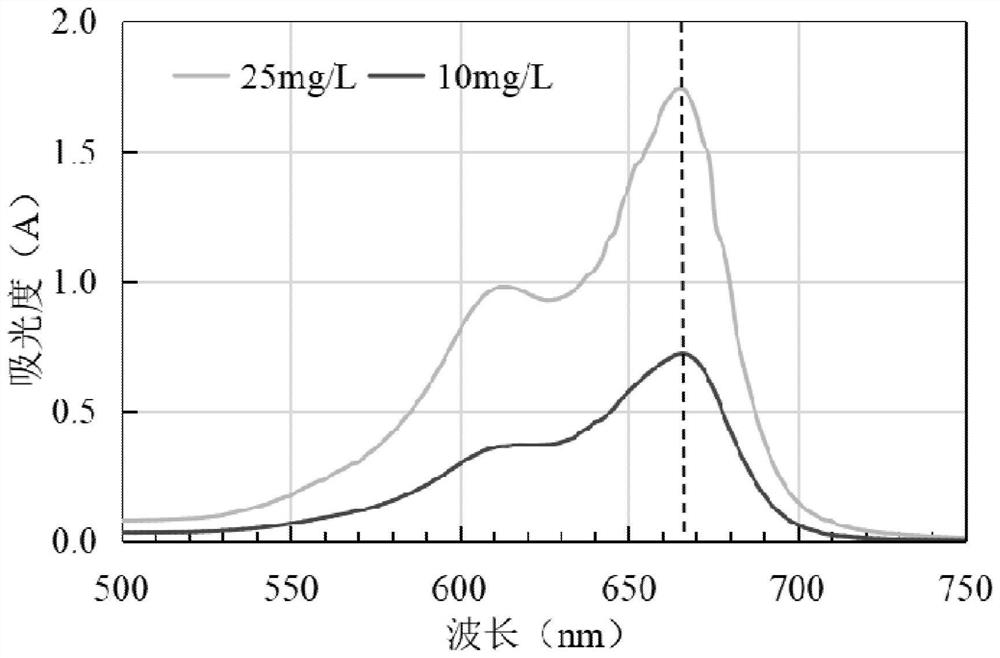

[0046] Test the absorption spectrum curves of different concentrations of methylene blue solutions according to the method of the present application, such as figure 1 . Such as figure 1 It can be seen that the shape and trend of the absorption spectrum curves of the methylene blue solutions with a concentration of 25mg / L and 10mg / L are exactly the same, and there are two absorption peaks, which are respectively located at 610nm and 664nm wavelengths, and then determine the methylene blue solution. The maximum absorption wavelength is 664nm.

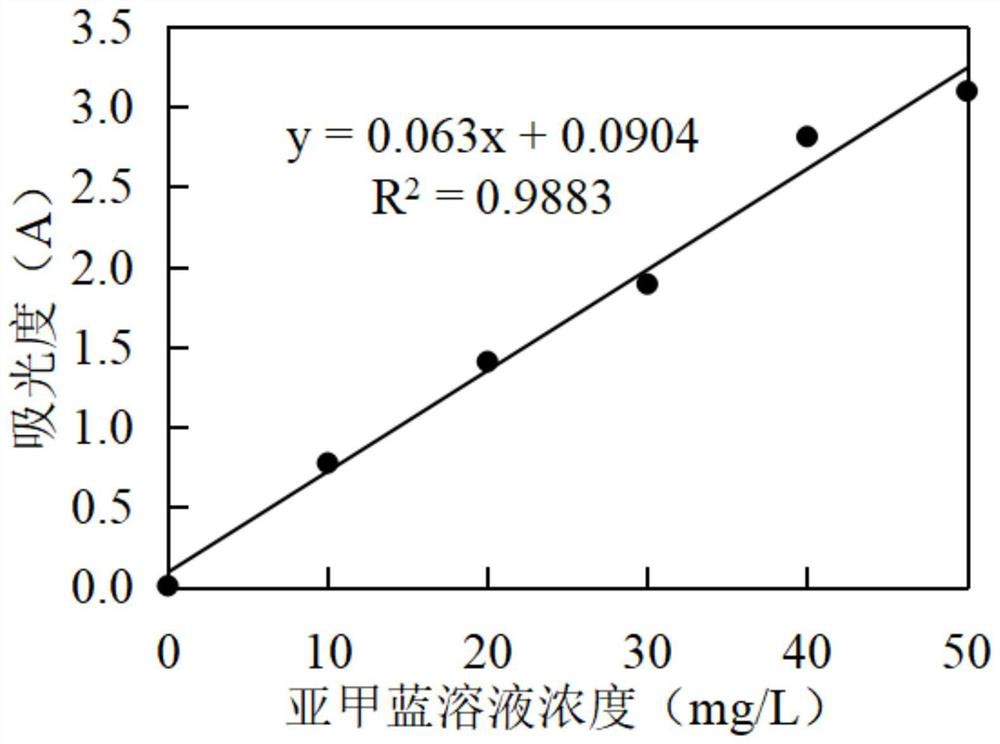

[0047] Carry out test according to the application method, establish the standard curve of methylene blue solution concentration and absorbance, figure 2 . Such as figure 2 It can be seen that the concentration of the methylene blue solution has a good linear positive correlation with the absorbance, and the correlation coefficient can reach more than 0.98. As the concentration increases, the absorbance shows a linear increase tre...

Embodiment 2

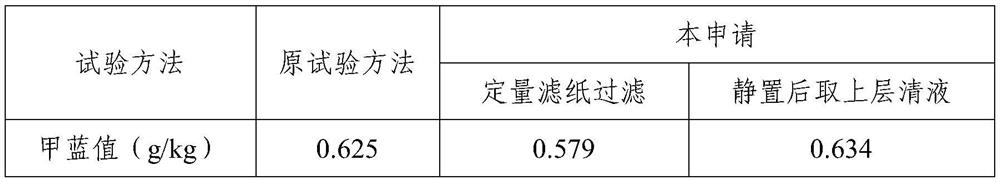

[0058] On the basis of Example 1, in order to reduce the errors caused by factors such as uneven mixing of the mixed solution and the presence of fine suspended particles in it. The application test method makes optimization correction in embodiment 2:

[0059] (1) There are fine suspended particles in the mixed solution of fine aggregate and methylene blue after standing, which will affect the determination of subsequent absorbance (traditional spectrophotometer tests are generally uniformly mixed solutions, and there is no such effect factor), add 30mL aqueous solution to the Erlenmeyer flask, and add 3g of 0-0.075mm particle size fine aggregate, mix well, and let stand for 5min. Use a straw to absorb 5 mL of the supernatant of the mixed solution in the Erlenmeyer flask, add water to dilute it 10 times, and obtain the solution to be tested. Use a spectrophotometer to detect the absorbance of the solution to be tested at a test wavelength of 664 nm, and compare it with the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com