A method for predicting shrinkage cavity closure during continuous casting billet reduction process

A calculation method and continuous casting billet technology, applied in the direction of calculation, design optimization/simulation, special data processing application, etc., to achieve the effect of enriching the theoretical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Prediction of shrinkage cavity closure during slab reduction:

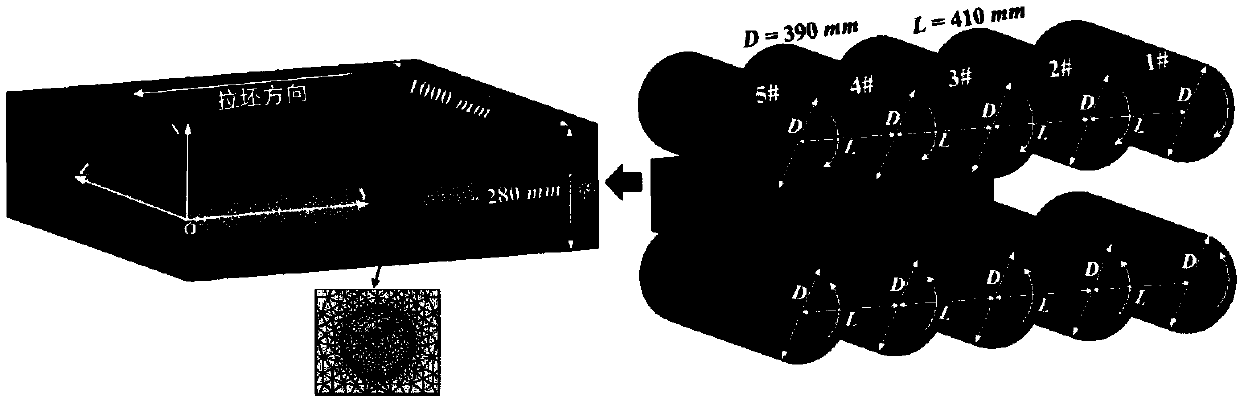

[0029] figure 1 The three-dimensional finite element model of the slab pressing process established for this example. In this example, the slab has a thickness of 280mm and a width of 2000mm. The slab pressing process is completed by sector sections, and each sector section contains 5 pairs of casting rolls (corresponding to figure 1 1#-5# in ), the diameter (D) of each pressing roller is 390mm, and the distance between rollers (L) in the casting direction is 410mm. According to the actual casting speed, the rotational speed of each casting roller in this example is set to 0.8 m / min. Since half of the width of the slab pressing process is selected to establish a three-dimensional finite element model, the attached figure 1 The cross-sectional dimension of the cast slab is 280mm (thickness) × 1000mm (half the width). The slab in the finite element model is divided by tetrahedral mesh, and the ...

Embodiment 2

[0032] Example 2 Prediction of shrinkage cavity closure during the reduction process of rectangular billet:

[0033] attached Figure 5 This is the three-dimensional finite element model of the rectangular billet pressing process established for this example. In this example, the rectangular blank has a thickness of 320mm and a width of 410mm. The reduction process of the rectangular billet is completed by the tension leveler. Each tension leveler contains 2 pairs of casting rolls, and the diameter of each roll down is 500mm. According to the actual casting speed, the rotation speed of each casting roll in this example is set to 0.42m / min. Since half of the width of the rectangular billet is selected to establish a three-dimensional finite element model, the attached Figure 5 The cross-sectional dimension of the cast slab is 320mm (thickness) × 212.5mm (half the width). The slab in the finite element model is divided by tetrahedral mesh, and the mesh size is about 10mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com