Sound emission detection sensor fixing device

A technology for fixing devices and sensors, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of uneven stress on sensors, poor adaptability of tank walls, etc., and achieve the effects of improving general adaptability, facilitating processing, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

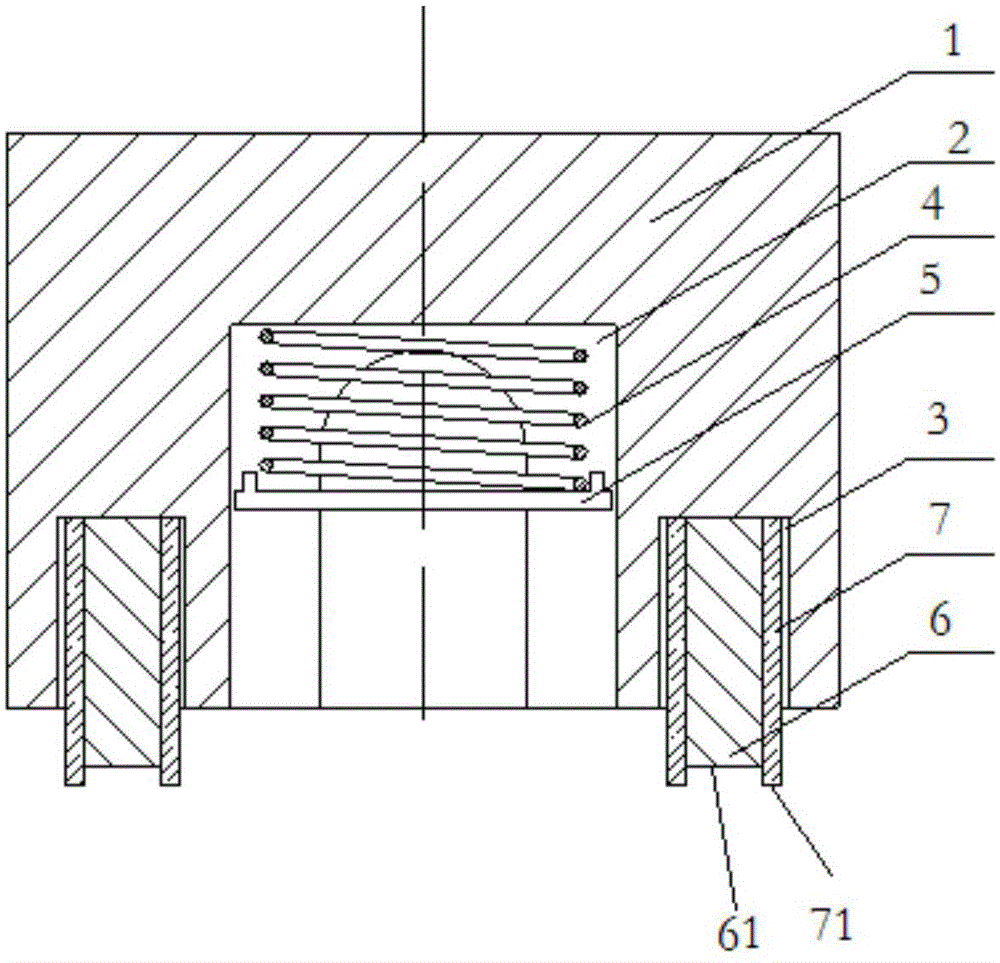

[0026] The embodiment of the present invention provides a fixing device for the acoustic emission detection sensor, which solves the problem of poor adaptability to the tank wall, excessive or too small magnetic force, and stress on the sensor in the prior art when the sensor is installed and fixed by a magnetic card holder. Uneven technical issues. The general adaptability to the surface to be measured is improved, and while ensuring a stable sensor, it also facilitates the removal of the fixing device.

[0027] In order to solve the technical problems in the above-mentioned prior art, the general idea of the technical solution provided by the embodiment of the present application is as follows:

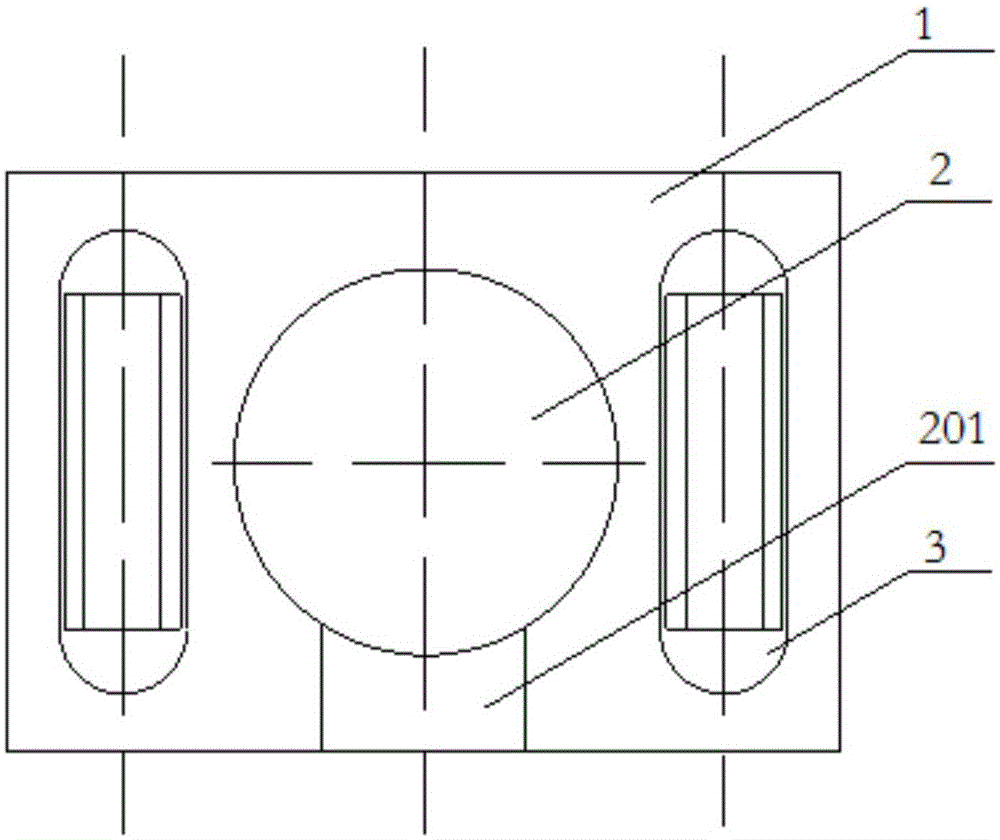

[0028] A sensor fixing device for acoustic emission detection, used for fixing the sensor on the tank wall surface, comprising:

[0029] A main body, a main body cavity and two accommodating cavities are opened on the first surface of the main body; the two accommodating cavities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com