Work-piece crack detection method based on an RFID (Radio Frequency Identification Device)

A crack detection and workpiece technology, which is applied in the field of RFID-based workpiece crack detection, can solve problems such as easy blind spots, troublesome workpiece detection, and high labor intensity, and achieve the effect of small size, flexible shape and easy operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

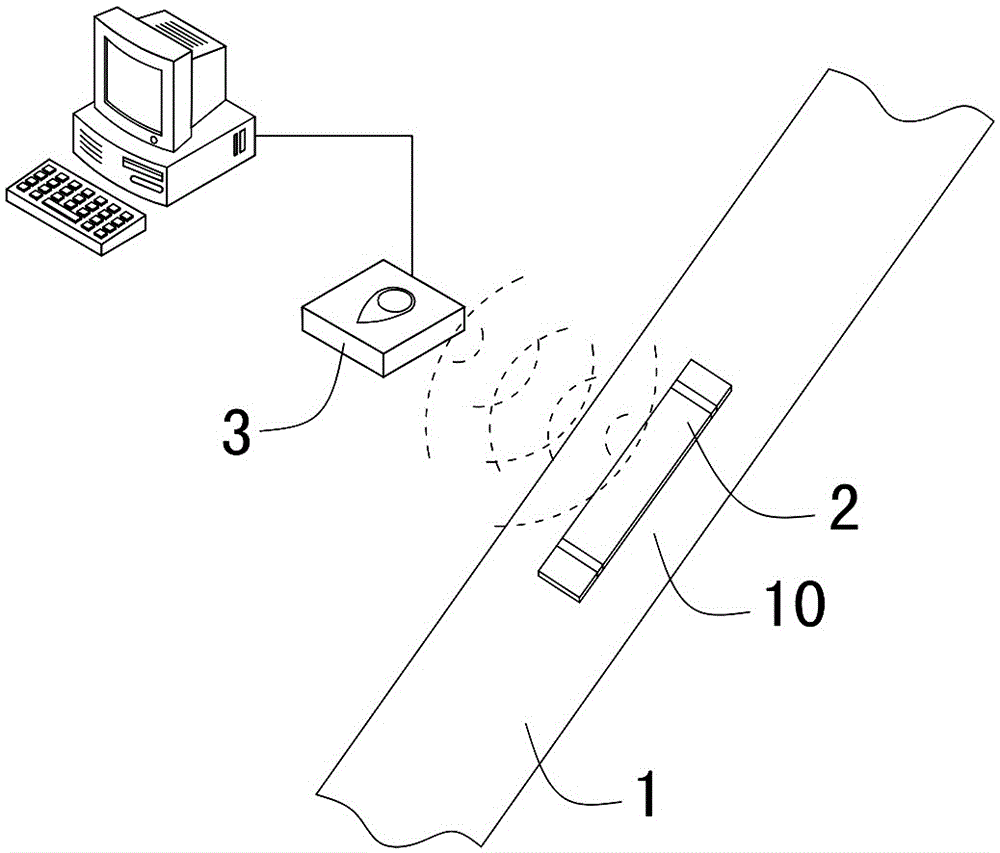

[0035] Hereinafter, taking the crack detection of the to-be-detected crack position 10 on the detected workpiece 1 having a rod-shaped structure as an example, the RFID-based workpiece crack detection method of the present invention will be further described in detail.

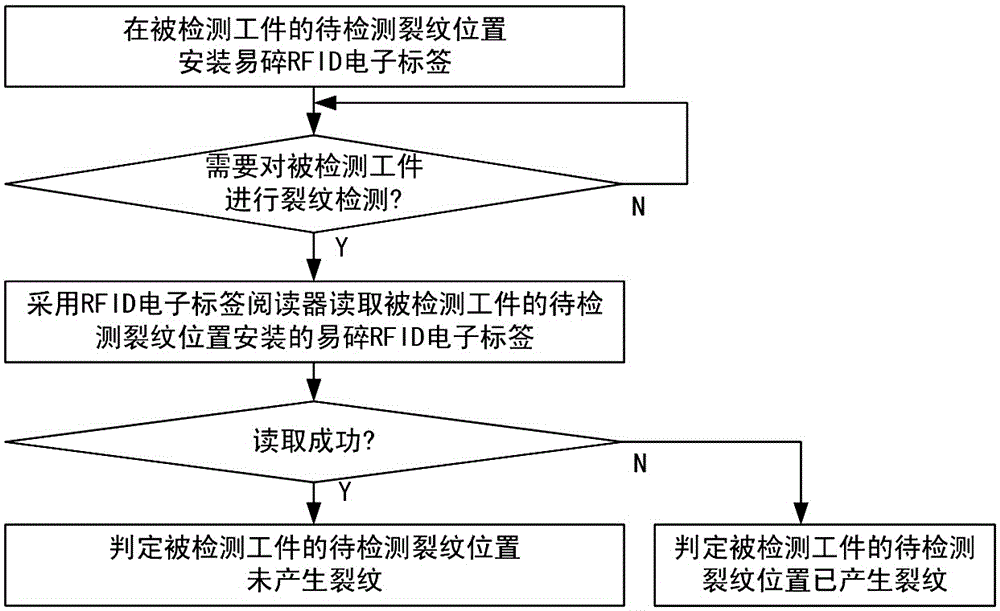

[0036] Such as figure 1 As shown, the steps of the RFID-based workpiece crack detection method in this embodiment include:

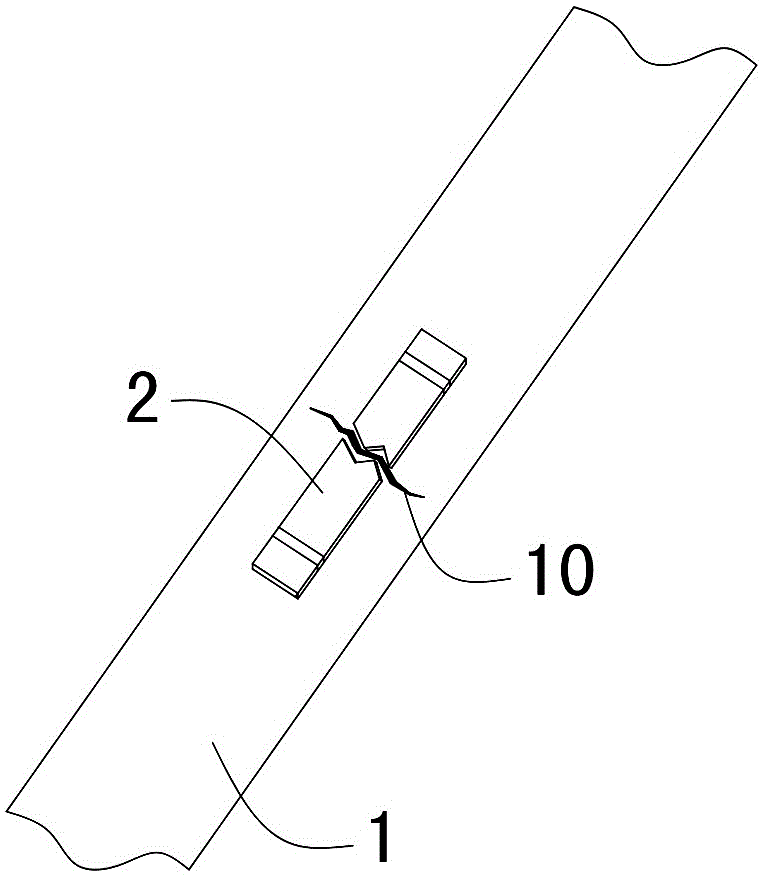

[0037] 1) Pre-install the fragile RFID electronic tag 2 at the crack position 10 to be detected on the workpiece 1 to be detected, so that the fragile RFID electronic tag 2 is respectively connected and fixed to both sides of the crack position 10 to be detected on the workpiece 1; see figure 2 One end of the fragile RFID electronic tag 2 is connected and fixed to one side of the crack position 10 to be detected on the workpiece 1 to be detected, and the other end is connected and fixed to the other side of the crack position 10 to be detected on the workpiece 1 to be detected.

[0038...

Embodiment 2

[0049] This embodiment is basically the same as the first embodiment, and the difference is that the structure of the workpiece 1 to be detected is different, and the position of the crack position 10 to be detected is different. The rod-shaped structure of the workpiece 1 to be detected in the first embodiment is somewhere on the rod where the crack position 10 is to be detected; Figure 4 and Figure 5 As shown, the workpiece 1 to be detected in this embodiment is a connecting rod assembly, and the crack position 10 to be detected is the root of the connecting ring at one end of the connecting rod assembly, and the root of the connecting ring is the position where cracks are most likely to occur in the connecting rod assembly. The RFID-based workpiece crack detection method of the present invention can quickly and conveniently detect whether cracks have occurred at the crack position 10 of the connecting rod assembly to ensure that the structure of the connecting rod assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com