Focusing device of large-beam electron beam shooting micro-beam spot X-ray source and application method of focusing device

An electron beam and X-ray technology, applied in the field of three-dimensional non-destructive microscopic observation, can solve the problems of slow beam switching process, weak X-ray intensity, and difficulty in reproducing sample growth and changes, so as to improve work efficiency and simplify complex adjustments , Reduce the effect of adjustment complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

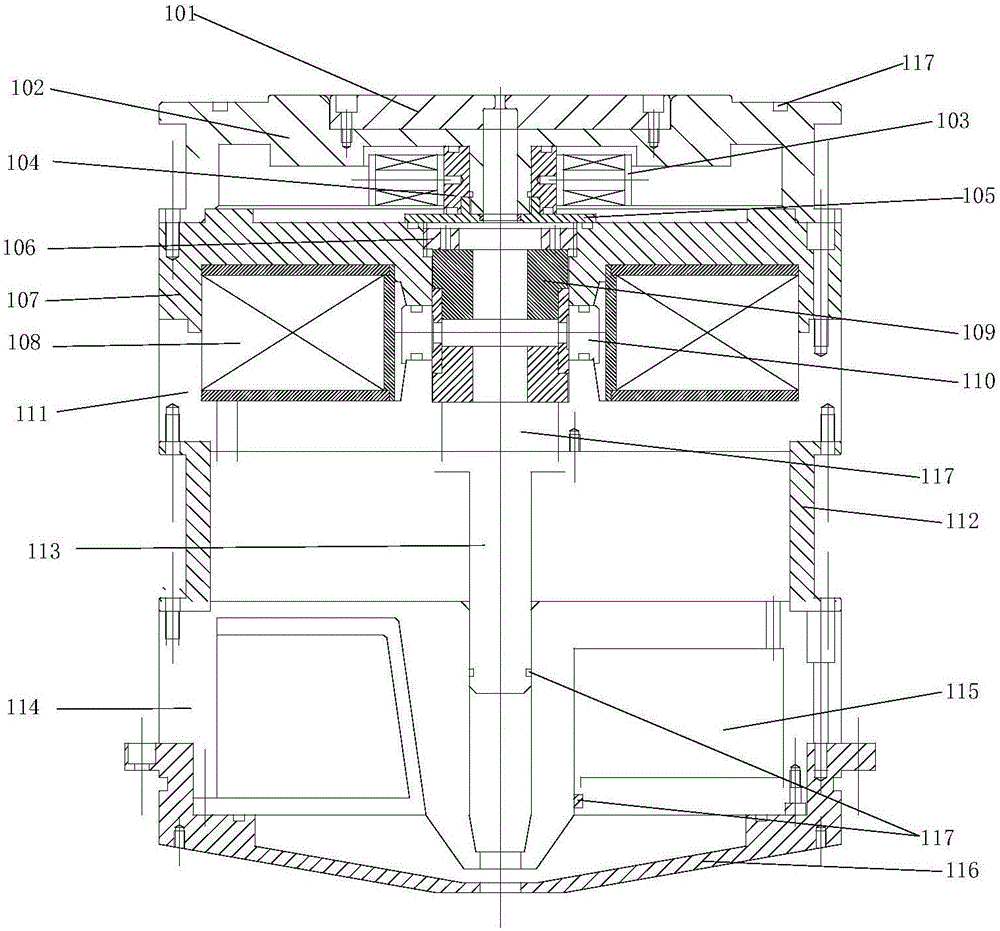

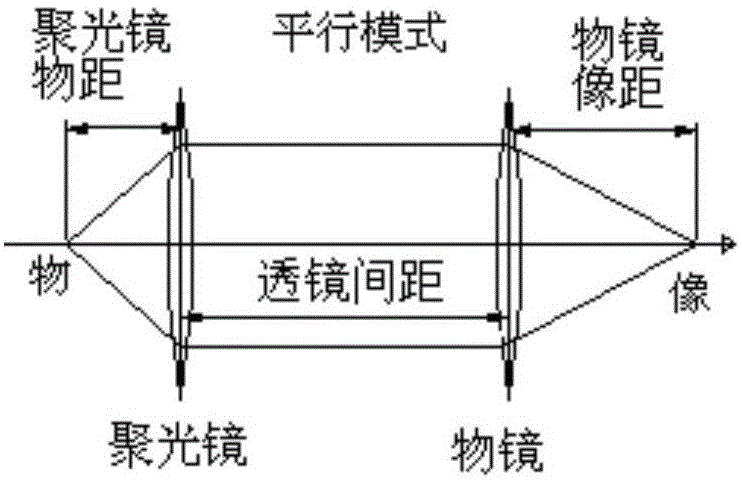

[0060] A focusing system device for a large-current electron beam targeting a micro-beam spot X-ray source, including an anode module, a centering coil module, a condenser lens module, an objective lens module, a movable diaphragm, a transition section module and an electron beam channel.

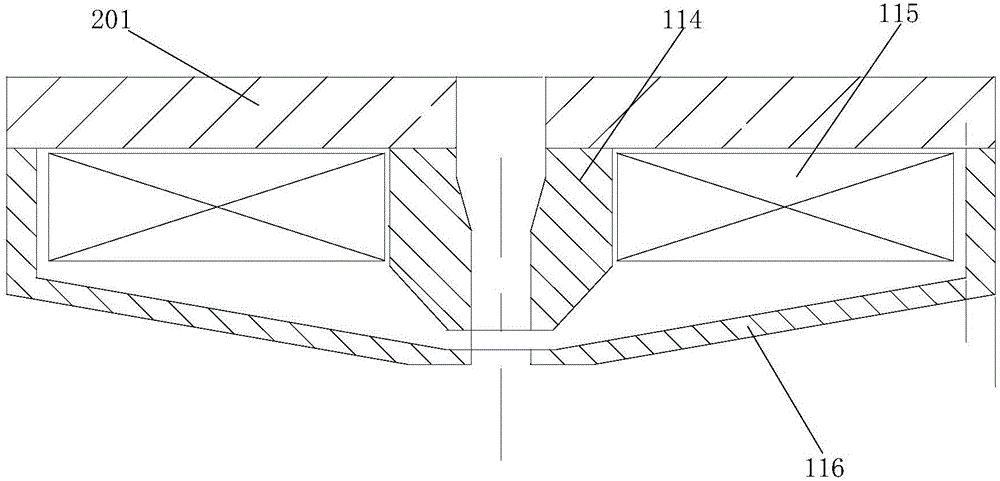

[0061] The focus system device is a cylindrical structure as a whole, such as figure 1 As shown, the electron beam channel 113 is located on the central axis of the focusing system device, and adopts a hollow magnetic permeable tube that disperses electrons, passing through the anode module, the centering coil module, the condenser lens module, the transition section module, and the objective lens module in sequence from top to bottom. reach the target plane; at the same time, two sealing rings 117 are set inside the electron beam channel 113 .

[0062] The anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com