An adaptive charging pile

A charging pile, self-adaptive technology, applied in circuits, current collectors, electric vehicles, etc., can solve the problems of difficult to control the rotation angle of the central rotating mechanism, large volume, and reduce self-weight, etc., to achieve beautiful design, flexible installation position, Guaranteed effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

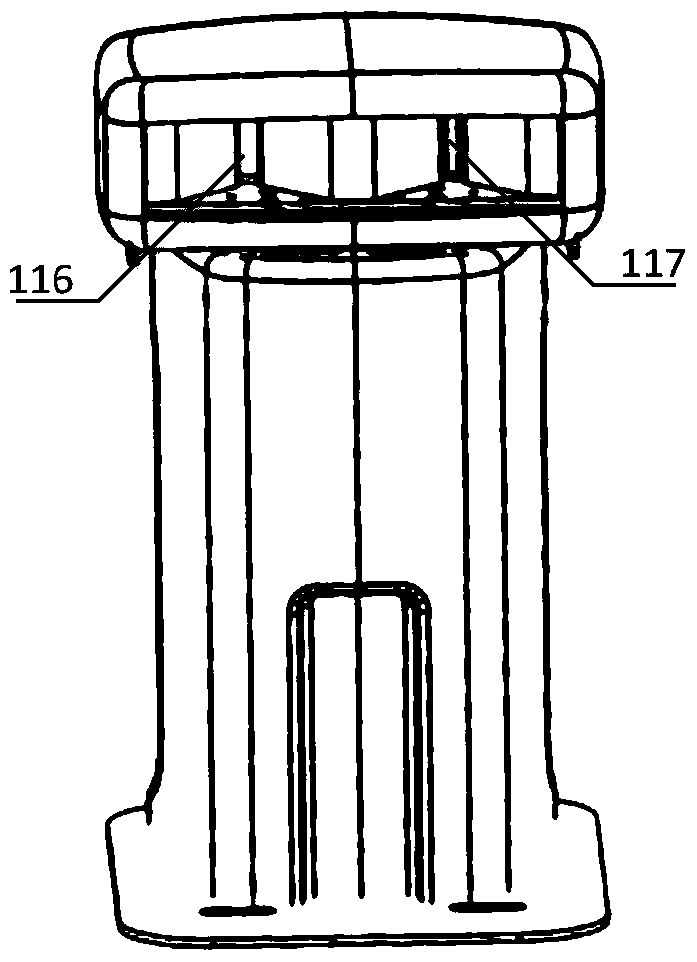

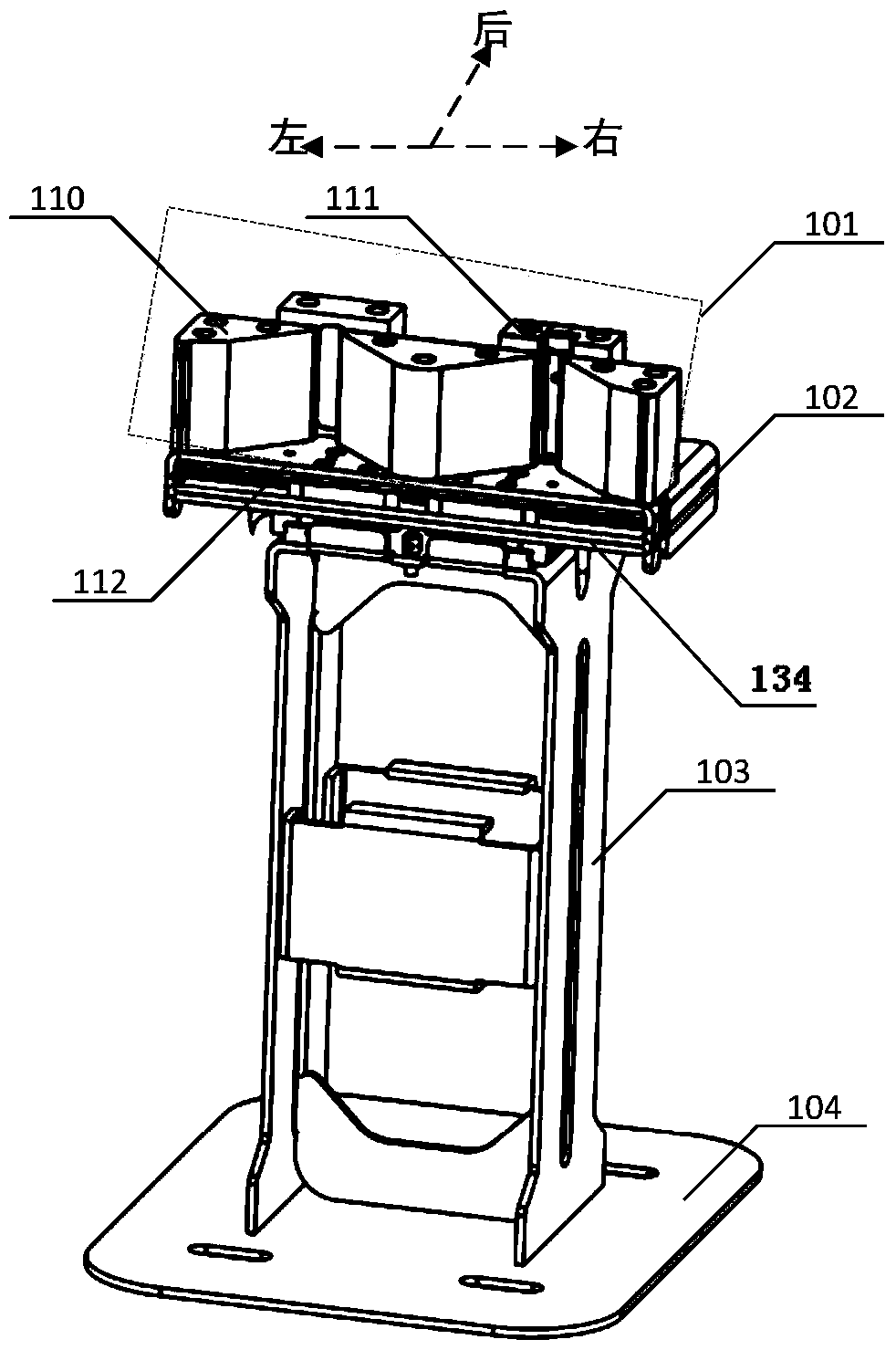

[0020] Such as figure 1 , 2 As shown in . The upper end of support column 103 is equipped with bottom support plate 134, and the lower end of support column is installed on the base 104, and the left end of the upper surface of bottom support plate 134, the right end are installed respectively left guide rail 133, right guide rail 131, the rear end of bottom support plate 134 A rear spring loading point 132 is installed at the middle position along the edge.

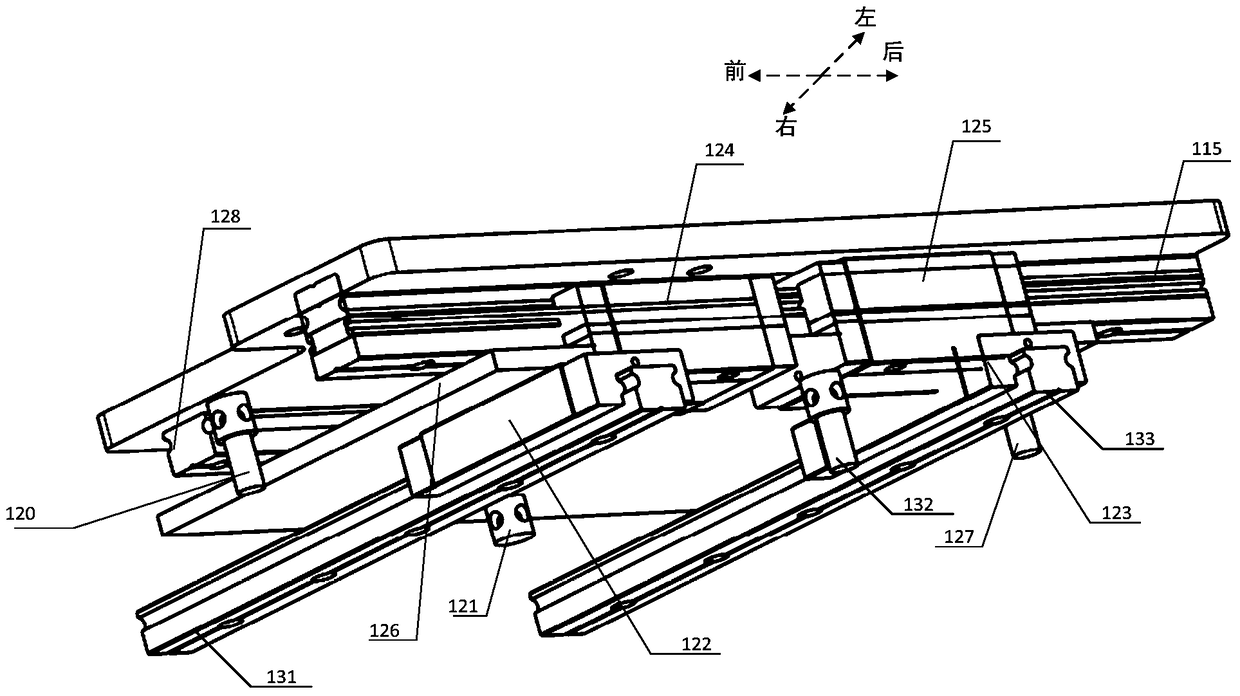

[0021] Such as figure 2 , 3 , 4, the position adjustment module 102 includes a rectangular middle support plate 126 and an electrode base plate 112; the front spring mounting point 121 and the left spring mounting point 127 are respectively set in the middle of the front end edge, left end edge, and right end edge of the middle support plate 126 , the right spring mounting point 120, the left end rear portion and the right end rear portion of the lower surface of the middle support plate 126 are respectively equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com