An Improved Multifunctional Transformer

A transformer, multi-functional technology, applied in transformer/inductor coil/winding/connection, conversion of AC power input to AC power output, conversion equipment that can be converted to DC without intermediate conversion, etc., can solve the saturable reactor module. The performance is not good enough to achieve the effect of simple structure, improved performance and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

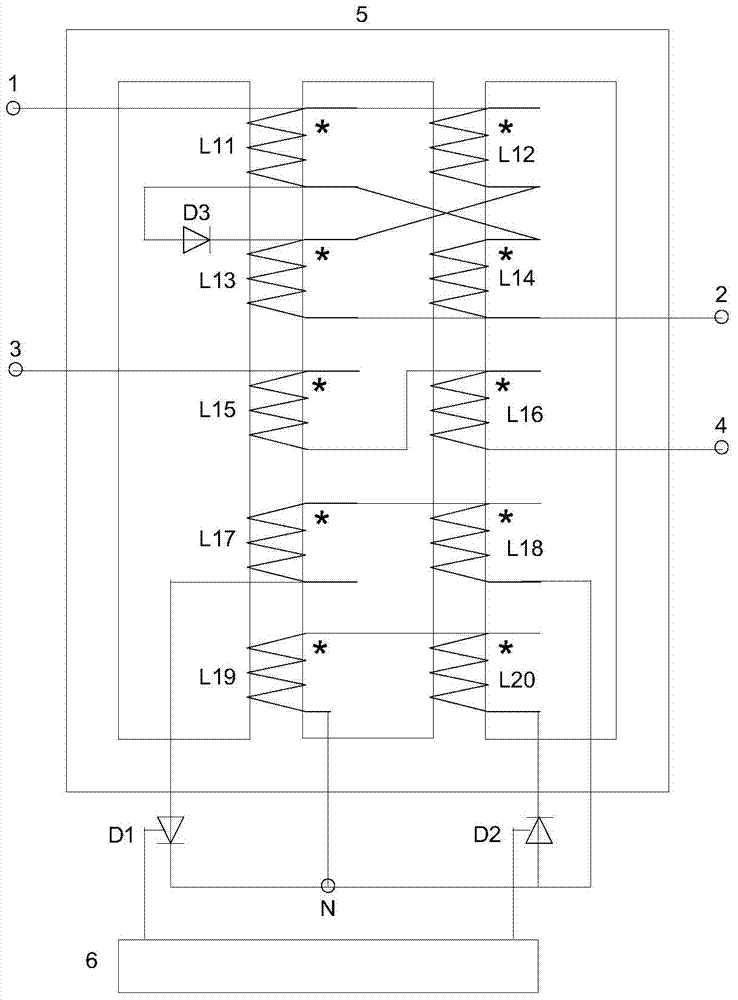

[0035] The structure and connection method of the multifunctional transformer proposed by CN 201510010431.0 are as follows: figure 1 shown. One of the iron core columns has AC coil L11, AC coil L13, AC coil L15, DC coil L17 and DC coil L19, and the other iron core column has AC coil L12, AC coil L14, AC coil L16, DC coil L18 and DC coil L20. There are four DC coils in total, and the turns of the four DC coils are relatively large. Therefore, the four DC coils can be improved to simplify the structure.

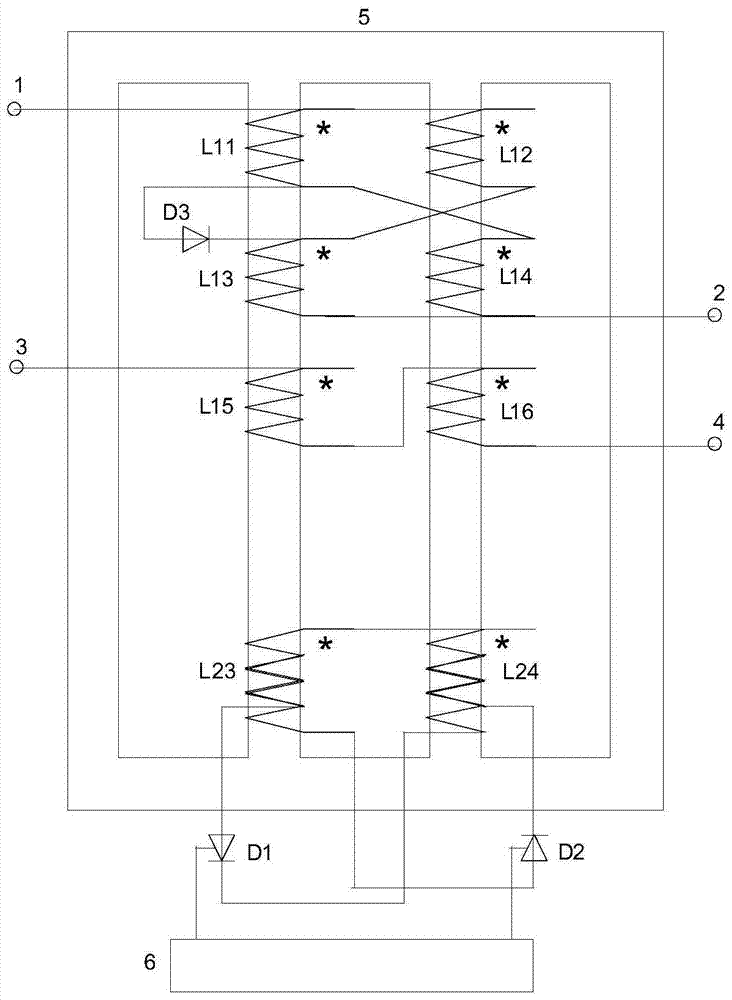

[0036] The structure and connection method of the first improved multifunctional transformer are as follows: figure 2 shown. Including primary coil terminal I1, primary coil terminal II2, secondary coil terminal I3, secondary coil terminal II4, closed-loop iron core 5, and control circuit 6. The closed-loop iron core of the first improved multifunctional transformer is the same as that of the existing saturated reactor. The first improved multifunctional transformer clos...

Embodiment 2

[0051] figure 1 The multifunction transformer shown is compatible with figure 2 The transient response time of the shown multifunctional transformer is relatively long. This embodiment provides a multifunctional transformer with shorter transient response time.

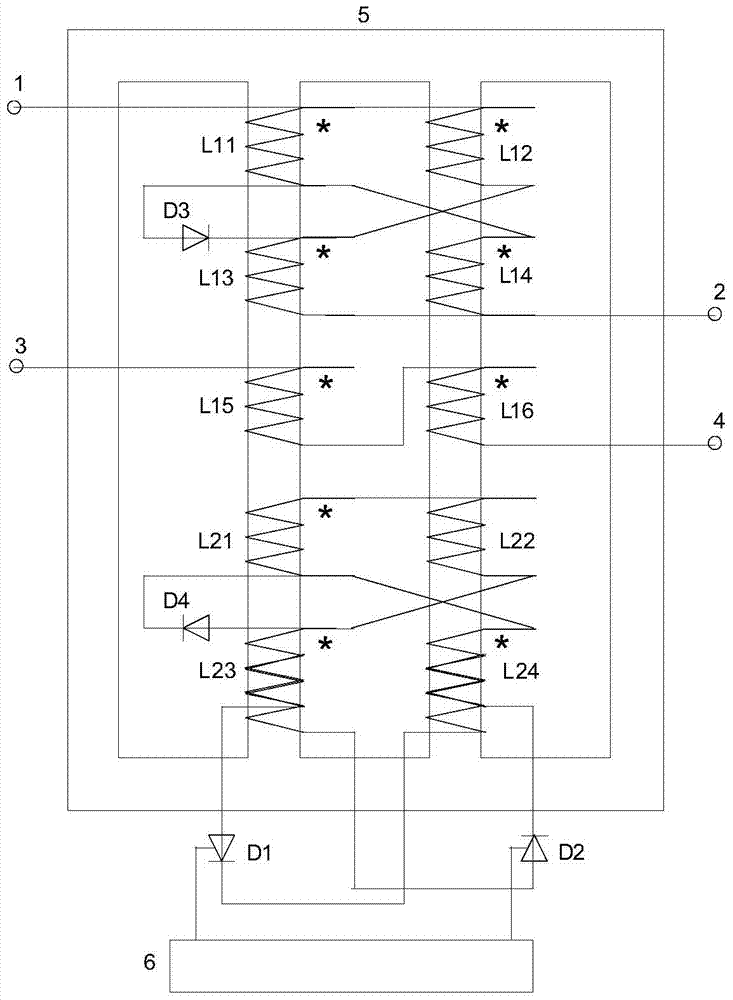

[0052] The structure and connection method of the second improved multifunctional transformer are as follows: image 3 shown. Including primary coil terminal I1, primary coil terminal II2, secondary coil terminal I3, secondary coil terminal II4, closed-loop iron core 5, and control circuit 6. The closed-loop iron core of the second improved multifunctional transformer is the same as that of Embodiment 1, so it is no longer redundant.

[0053] One of the iron core columns has AC coil L11, AC coil L13, AC coil L15, DC coil L21 and DC coil L23, and the other iron core column has AC coil L12, AC coil L14, AC coil L16, DC coil L22 and DC coil L24; the number of turns of AC coil L11, AC coil L12, AC coil L13, and AC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com