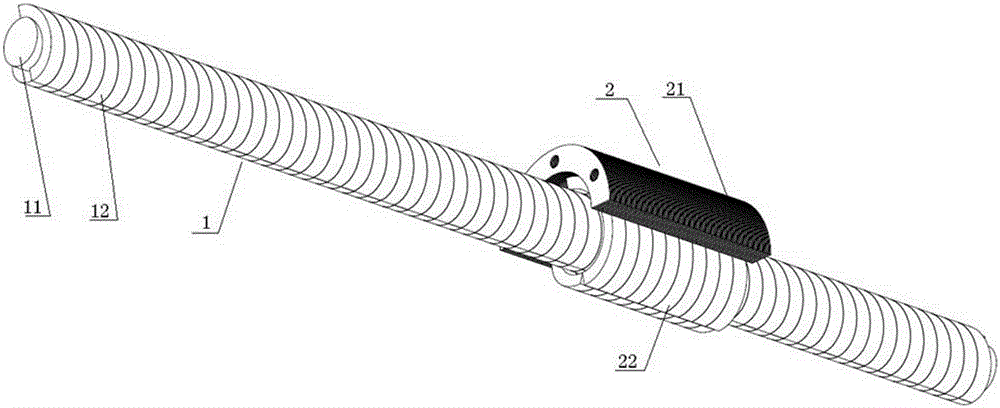

Permanent magnet screw rod device and splicing method thereof

A technology of permanent magnets and screw rods, which is applied in the direction of electrical components, generators/motors, etc., and can solve problems such as manufacturing difficulties and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Step S1 includes:

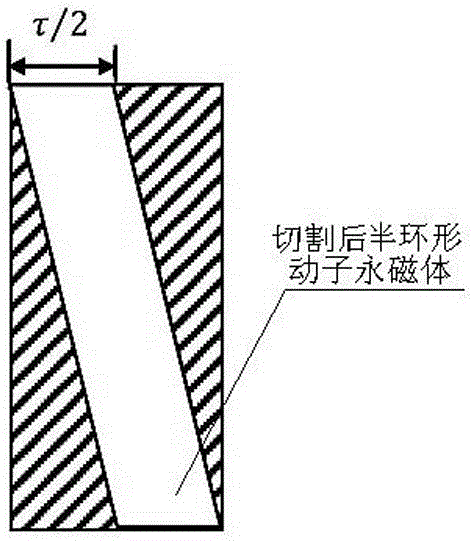

[0076] S1.1A, use the wire cutting method to cut each N-pole semi-annular mover permanent magnet and each S-pole semi-annular mover permanent magnet of the permanent magnet screw shaft 1, so that each N-pole semi-annular mover The permanent magnets and each S-pole semi-annular mover permanent magnet are oblique tile-shaped, and the side surfaces of each N-pole semi-annular mover permanent magnet and each S-pole semi-annular mover permanent magnet are parallelogram-shaped.

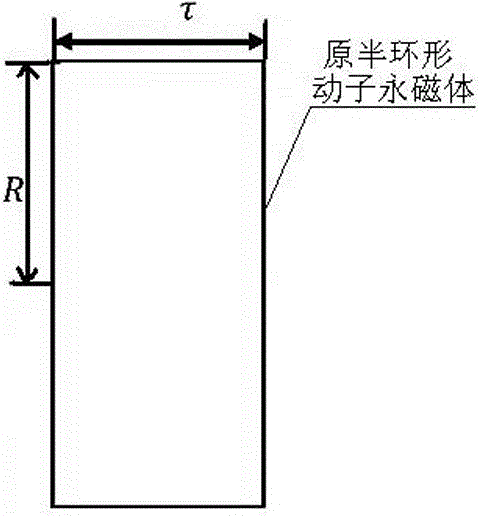

[0077] Such as Figure 2a As shown, the radius of the original N-pole semi-annular mover permanent magnet 12 or the S-pole semi-annular mover permanent magnet is R, and the cross-sectional width is τ. cut out as Figure 2b The shaded part shown makes the remaining part form a slanted shoe shape, that is, form the required 180° helical permanent magnet. Such as Figure 2b As shown, the cross-section of the N-pole semi-annular mover permanent magnet or the S-pole semi-annular mo...

Embodiment 2

[0096] Step S1 includes:

[0097] S1.1B, will be as Figure 2a , Figure 3a Each N-pole half-ring mover permanent magnet and each S-pole half-ring mover permanent magnet of the permanent magnet screw shaft 1 shown rotates along the axis direction angle, such as Figure 4 As shown, the top and bottom of the N-pole semi-annular mover permanent magnet and the top and bottom of the S-pole semi-annular mover permanent magnet are cut by wire cutting method, so that the N-pole semi-annular mover permanent magnet 1. The side of the S-pole semi-annular mover permanent magnet forms a parallelogram; the top and bottom of the N-pole semi-annular mover permanent magnet are all parallel to the axis, and the top and bottom of the S-pole semi-annular mover permanent magnet are all parallel to the axis. parallel. Thereby forming the required 180° helical N pole semi-annular mover permanent magnet and S pole semi-annular mover permanent magnet.

[0098] Among them, the size of each N-pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com