Active matrix liquid crystal display with special aspect ratio and laser cutting and manufacturing method therefor

A liquid crystal display and active matrix technology, which is applied in the field of special aspect ratio active matrix liquid crystal display and its laser cutting manufacturing, can solve the mismatch of market capacity of square TFT liquid crystal display, the disconnection between market demand and production, and the difficulty in recovering investment and other problems, to achieve the effect of no commercial risk, low price, and extended application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

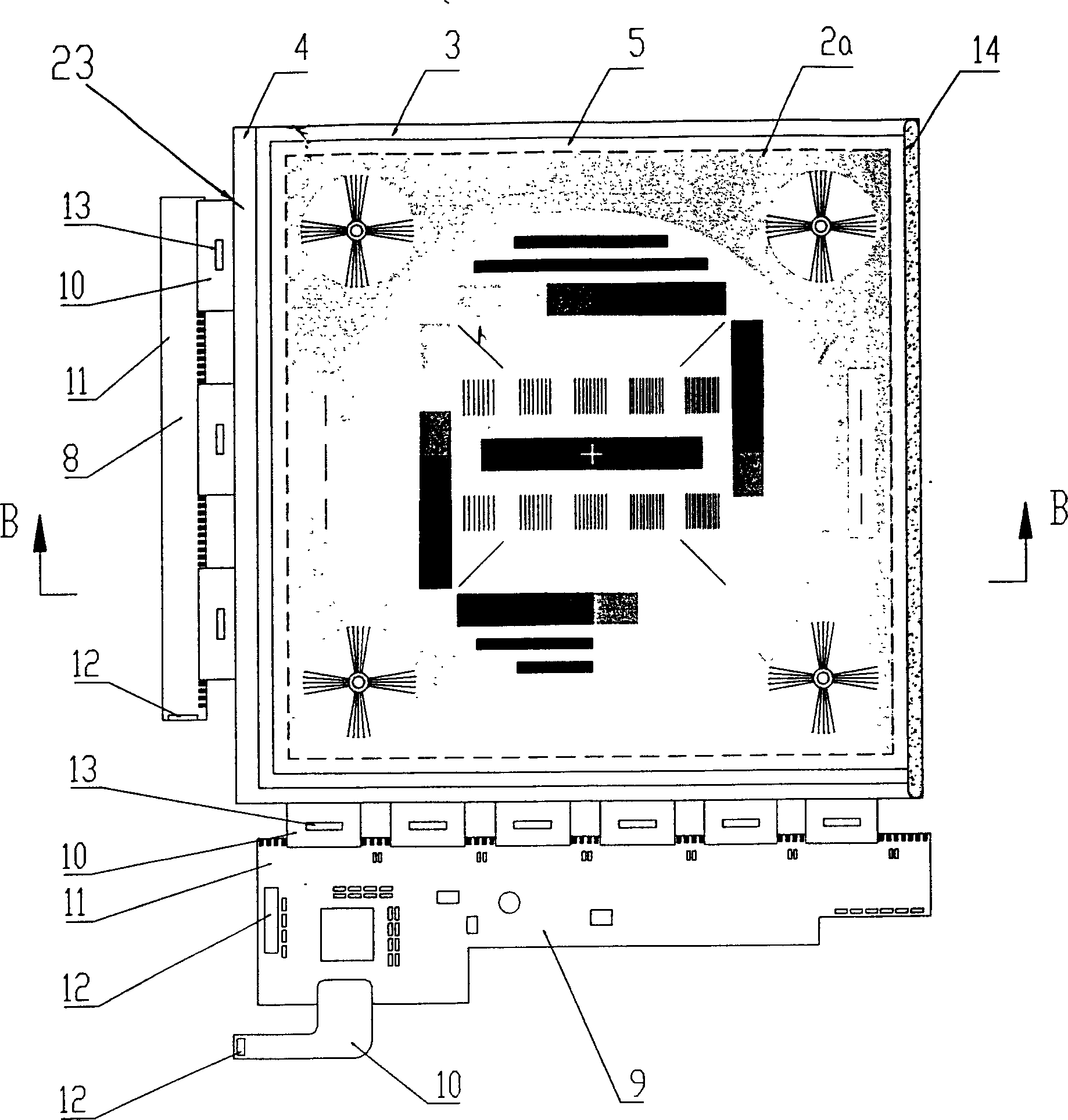

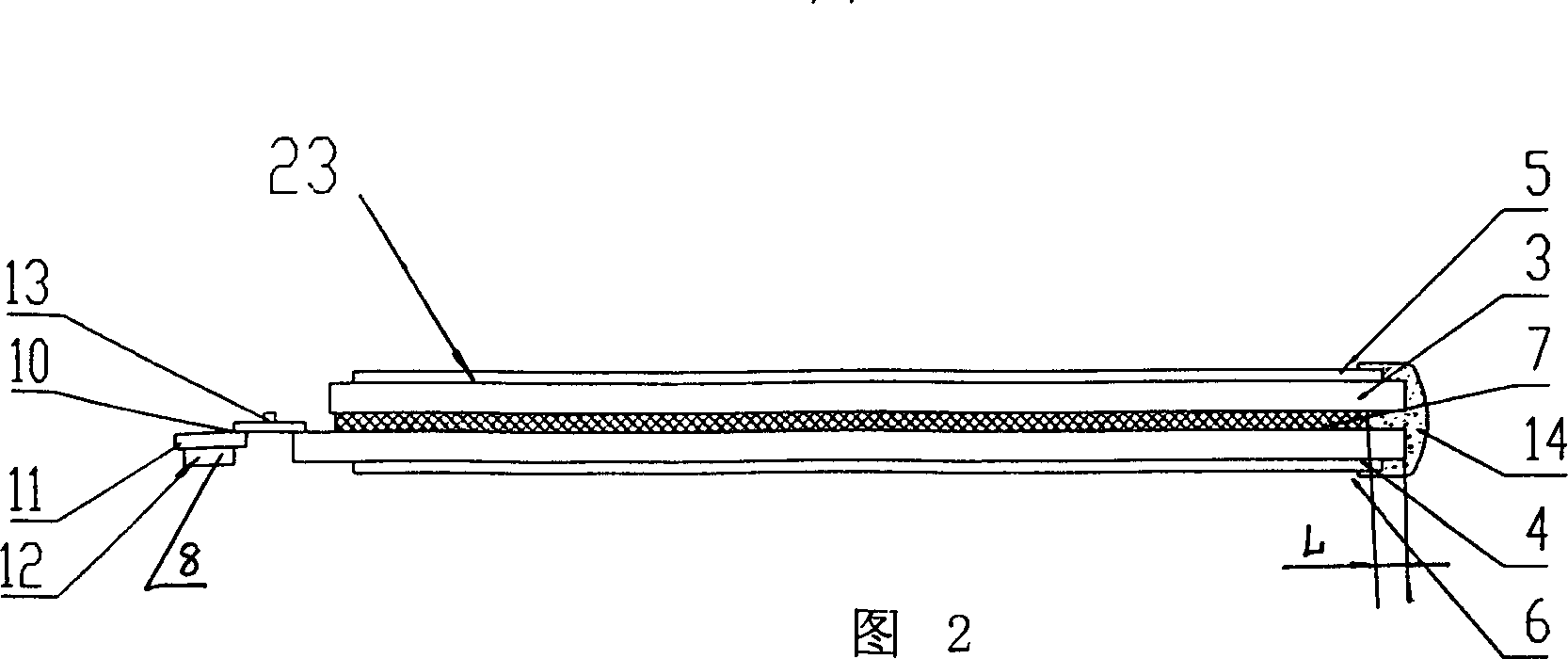

[0050] Such as figure 1 , 2, 5, 6, 7, 8, and 9.

[0051] A square active matrix liquid crystal display (such as figure 1 , 2), using as Figure 5 , The rows and columns shown in 6 are all finished active matrix liquid crystal displays led by unilateral electrodes or such as Figure 7 The finished product active matrix liquid crystal display shown in . Glue 14, sealing glue 14 contact with the upper polarizing plate 5 of forming display 22, upper glass substrate 3, liquid crystal material 7, lower glass substrate 4, lower polarizing plate 6 respectively (as figure 1 , 2 shown).

[0052] The manufacturing method of above-mentioned square (or aspect ratio is non-4: 3 and 16: 9 ratio) active matrix liquid crystal display is:

[0053] a. Decomposition: Take the finished active matrix liquid crystal display module with an aspect ratio of 4:3 or 16:9 and a unilateral lead-out structure of row scanning electrodes (or a single side of the row, and lead-out of double-sided electrod...

Embodiment 2

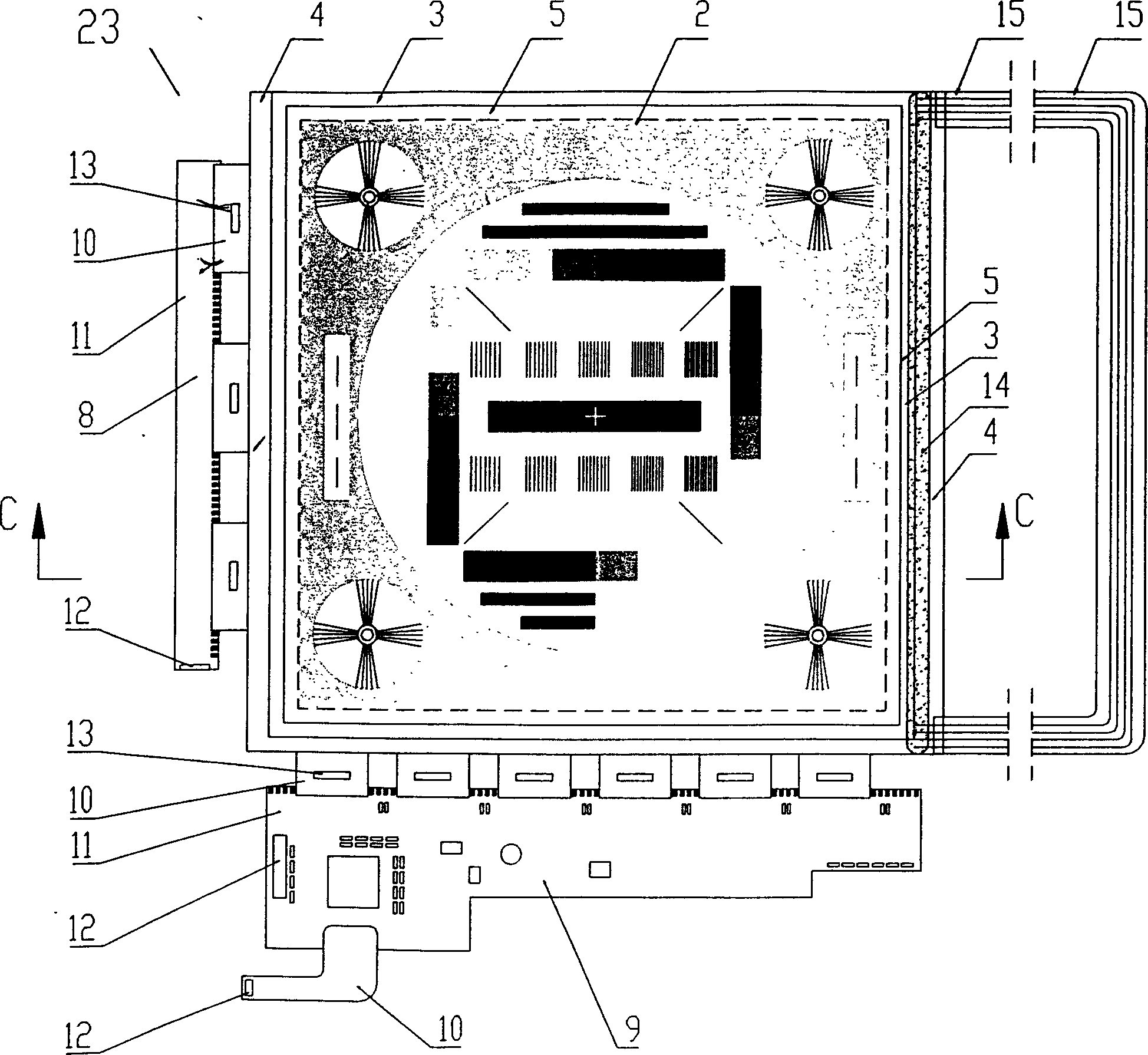

[0073] Such as image 3 , 4, 5, 6, 7, 8, and 9. A square active matrix liquid crystal display (such as image 3 , 4), using the Figure 5 , The rows and columns shown in 6 are all finished active matrix liquid crystal displays led by unilateral electrodes or such as Figure 7 , The finished product active matrix liquid crystal display shown in 8 is cut and formed, and the aspect ratio of display 22 is 1: 1 (also can be any ratio), and one side of display 22 is the staggered cutting edge, and the staggered cutting edge The upper package is provided with a sealing glue 14, and the sealing glue 14 is either in contact with the upper glass substrate 3 and the liquid crystal material 7, or is in contact with the lower glass substrate 4 and the liquid crystal material 7, such as image 3 , 4.

[0074] The manufacturing method of above-mentioned square (or aspect ratio is non-4: 3 and 16: 9 ratio) active matrix liquid crystal display is:

[0075] a. Decomposition: Take the finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com