Filling type pollen feeder

A filling and powdering device technology, which is applied in the field of bee breeding, can solve the problems of bee waste, bee colony lack of powder, time-consuming and labor-intensive problems, and achieve the effect of simple and convenient operation, large capacity and improved feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

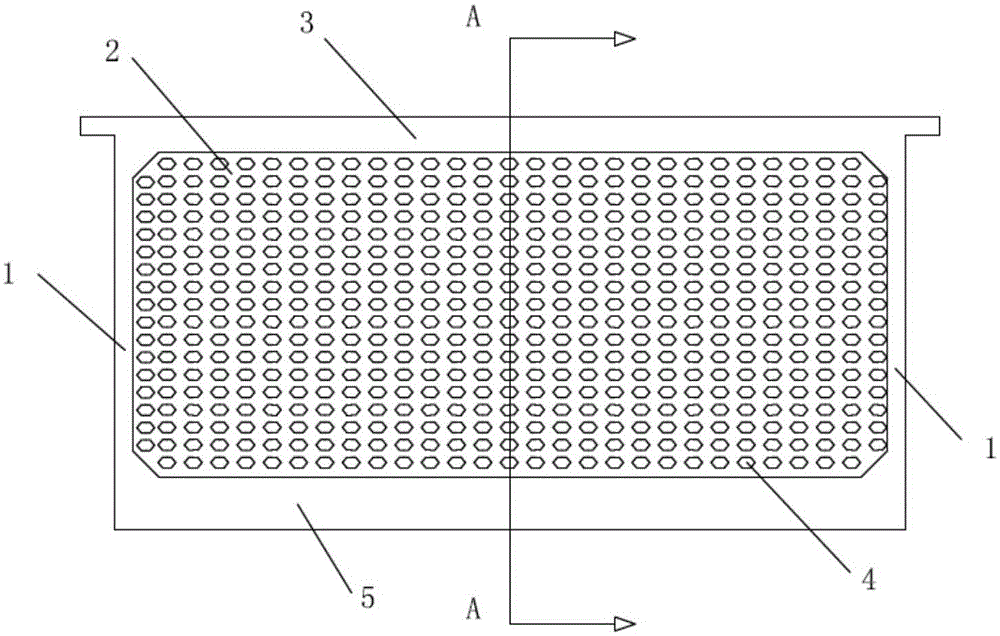

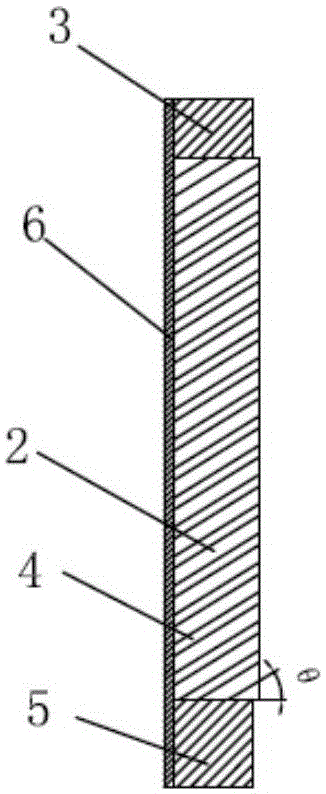

[0045] Such as Figure 1-3 As shown, the filling type powder feeder provided by the present invention is specifically described, including a powder feeder body with openings on the side, the powder feeder body includes a frame arranged on the bottom plate 6, and the frame includes 3 and the side plates 1 on both sides of the lower beam 5, in the present embodiment, the frame width is 27cm, the length is 45cm, and the thickness is 3cm; the width of the side plate 1 is 1.5cm, the length is 22.5cm, and the thickness is 3cm; the opening is embedded with a powder feeder 2, the honeycomb hole 4 of the powder feeder 2 and the horizontal plane are provided with an upward inclination angle θ, and the value of the inclination angle θ is 30° to 60°, preferably the inclination angle θ The value is 35°-50°, and more preferably, the value of the inclination angle θ is 40° or 45°. The powder feeder 2 is rectangular, and several adjacent honeycomb holes 4 are arranged in the rectangle, the w...

Embodiment 2

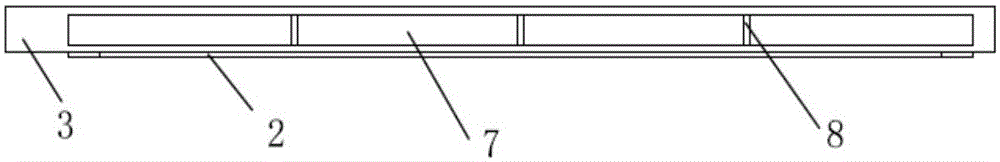

[0047] Such as Figure 4-6 As shown, this embodiment has been improved on the basis of Embodiment 1, and other structures are the same, the difference is: the filling type powder feeder provided by the present invention, the top surface of the powder feeder 2 is set on the lower side of the upper beam 3 There is a downward arc structure 13, the distance from the bottom edge of the arc structure 13 to the upper beam 3 is 3-10 cm, 6 cm or 7.6 cm in this embodiment, and the upper beam 3 is provided with a syrup opening upward Pool, the upper beam 3 is provided with a syrup pool with an upward opening, including a first syrup pool 7 and a second syrup pool 9 that are arranged symmetrically to the center of the upper beam 3 and separated by a partition 8, the first syrup pool 7 The shape of the bottom surface of the second syrup pool 9 and the shape of the arc-shaped structure 13 are arranged corresponding to each other.

Embodiment 3

[0049] Such as Figure 7As shown, this embodiment has been improved on the basis of Embodiment 1, and other structures are the same, the difference is that: the powder feeder 2 includes several transverse partitions 10 and longitudinal partitions 11 arranged across each other in the opening, so A plurality of sequentially arranged honeycomb holes 4 are formed between the transverse partition 10 and the longitudinal partition 11. The length of the honeycomb holes 4 is 0.5-2.0 cm, preferably 1.5 cm, and the width is 0.5-1.5 cm, preferably 1.0 cm. The honeycomb hole 4 and the horizontal plane are provided with an upward inclination angle θ, the value of the inclination angle θ is 30° to 60°, preferably, the value of the inclination angle θ is 35° to 50°, and preferably, the value of the inclination angle θ is 40° or 45°.

[0050] The specific usage method of the filling type powder feeder provided by the present invention is as follows:

[0051] 1. Mix the pollen or substitute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com