Making technology for potato noodles

A technology of potato noodles and production process, which is applied in the directions of food preparation, food drying, food science, etc., can solve problems such as the adverse effects of mechanical properties and mechanical properties and other processing characteristics, reduce the taste and nutritional value of potatoes, etc., and achieve a strong taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

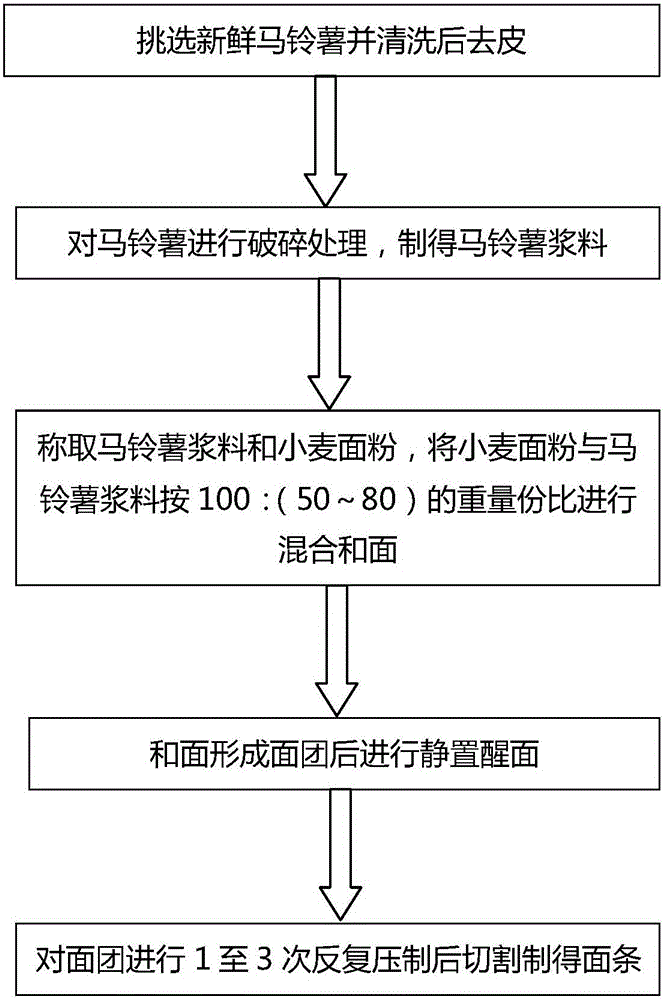

Image

Examples

Embodiment 1

[0036] Step 1. Select fresh potatoes, clean them, and remove the potato skins. The dry matter content of the selected potato raw materials is more than 18%;

[0037] Step 2, crushing the potatoes to make a potato slurry;

[0038] Step 3, take by weighing 480g potato slurry and 800g wheat flour, mix the two and make dough;

[0039] Step 4. After kneading the dough into a dough, rest it for 30 minutes;

[0040] Step 5, then carry out 2 repeated pressings through the noodle machine to the dough after waking up, and then cut through the noodle machine to make noodles;

[0041] Boil the prepared noodles in water, take them out after they are cooked, and add condiments such as oil, salt, soy sauce and vinegar to prepare according to personal taste. The potato noodles prepared by the above method have a pure taste of potatoes and contain many nutrients beneficial to the human body. Nutrients.

[0042] When fresh potatoes with higher dry matter content are selected for kneading wit...

Embodiment 2

[0045] Step 1. Select fresh potatoes, clean them, and remove the potato skins. The dry matter content of the selected potato raw materials is more than 18%;

[0046] Step 2, crushing the potatoes to make a potato slurry;

[0047] Step 3, take by weighing 560g potato slurry and 800g wheat flour, mix the two;

[0048] Step 4: After kneading the dough into a ball, let it rest for 60 minutes;

[0049] Step 5, then the dough after waking up is pressed repeatedly through a noodle machine for 3 times, and then cut by a noodle machine to obtain noodles;

[0050] Step 6, dehydrating the cut noodles at 50° C. by means of an electric blast drying method to obtain dry noodles (ie dried noodles).

[0051] Boil the dried noodles, take them out after they are cooked, and add condiments such as oil, salt, soy sauce and vinegar according to personal taste. The dried potato noodles prepared by the above method have pure potato taste. , Contain many nutritious substances beneficial to human b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com