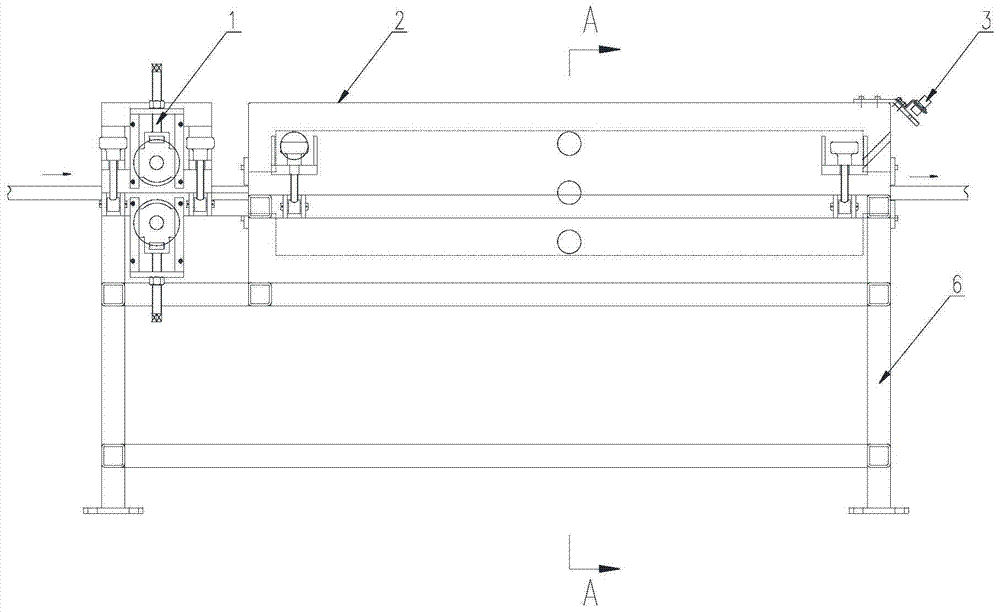

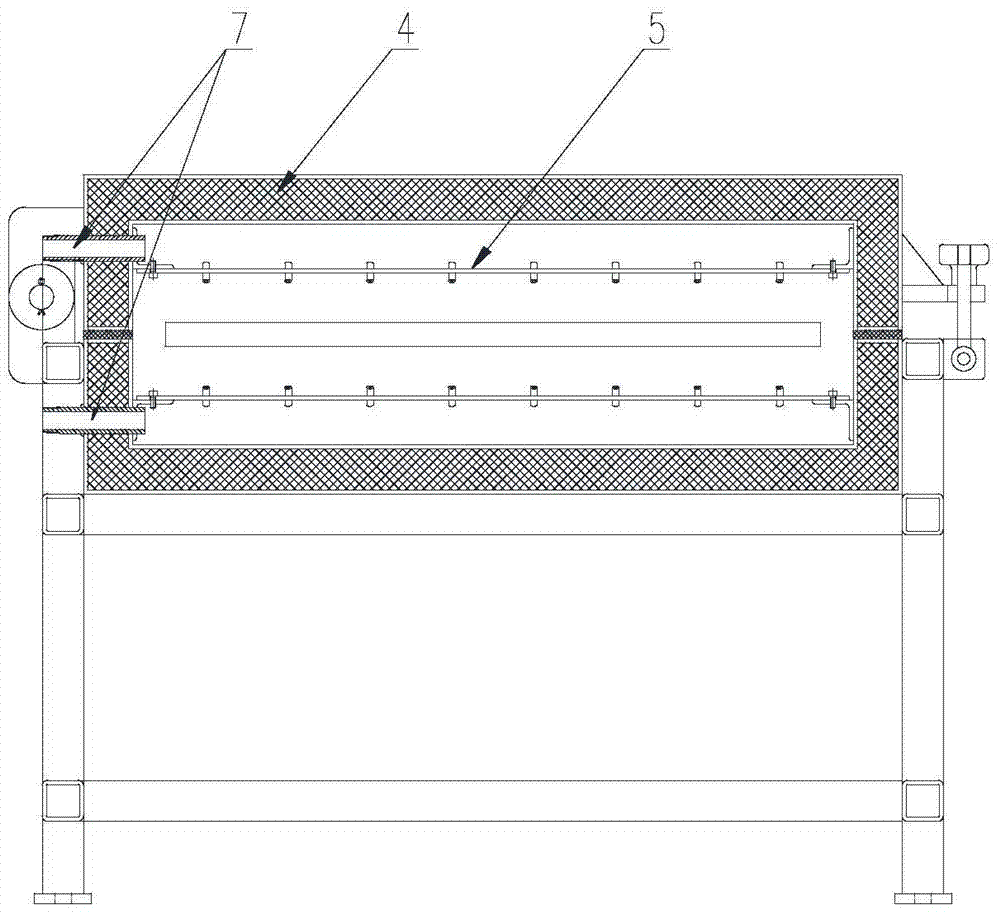

Magnesium alloy extruded plate online hot air heating device and heating coiling method

A hot air heating device and magnesium alloy technology, which is applied in the field of magnesium alloy strip production and processing, can solve the problems of not recommending, quality cannot be guaranteed, and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0041] Cast rod specification: Φ510mm×1500mm

[0042] Extrusion machine: 7500 tons extrusion machine

[0043] Extruded sheet specifications: thickness 8mm, width 500mm

[0044] The process steps of this embodiment are:

[0045] 1) Extrusion: The cast rod is heated in a heating furnace to 400-460°C for 1-2 hours, and then sent to an extrusion machine for extrusion at a speed of 1-3m / min.

[0046] 2) Hot air generator: start the hot air generator during extrusion, the temperature adjustment range is 200-500°C, the initial temperature is adjusted to 400-500°C, and it is adjusted according to the plate temperature during the production process.

[0047] 3) Magnesium alloy extruded plate is heated by online hot air heating device: according to the thickness and width of magnesium alloy extruded plate (magnesium alloy plate), the specification of this heating device is selected as: 195×1000×1200mm, and the number of hot air nozzles is 8×10. The blowing angle is 60°, and the dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com