Saving type duplex stainless steel and preparation method thereof

A duplex stainless steel, economical technology, applied in the field of economical duplex stainless steel and its preparation, can solve the problems of insufficient formability and corrosion resistance, elongation not meeting the reference value, plastic anisotropy increase, etc., to achieve improved Productivity, omission of surface grinding process, effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the corresponding drawings so that those skilled in the art can easily implement the present invention. However, the described embodiments can be changed in various ways, and the invention is not limited to the embodiments provided in this specification but is illustrated by way of example.

[0069] For reference, in description of the present invention, known functions or constructions will not be described in detail since it would unnecessarily obscure the understanding of the present invention.

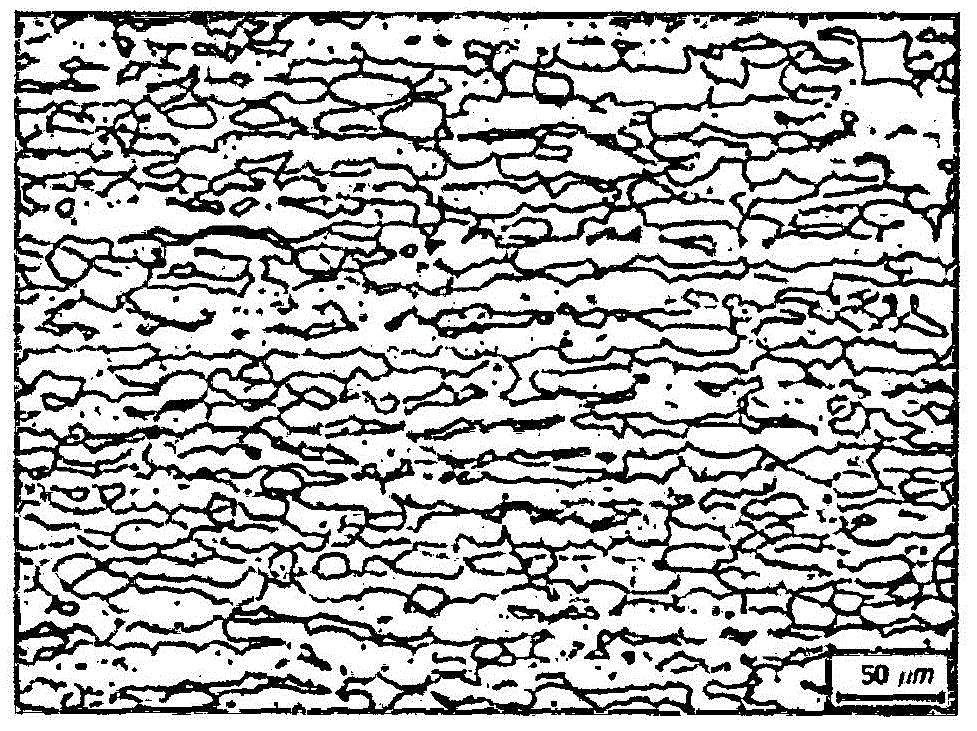

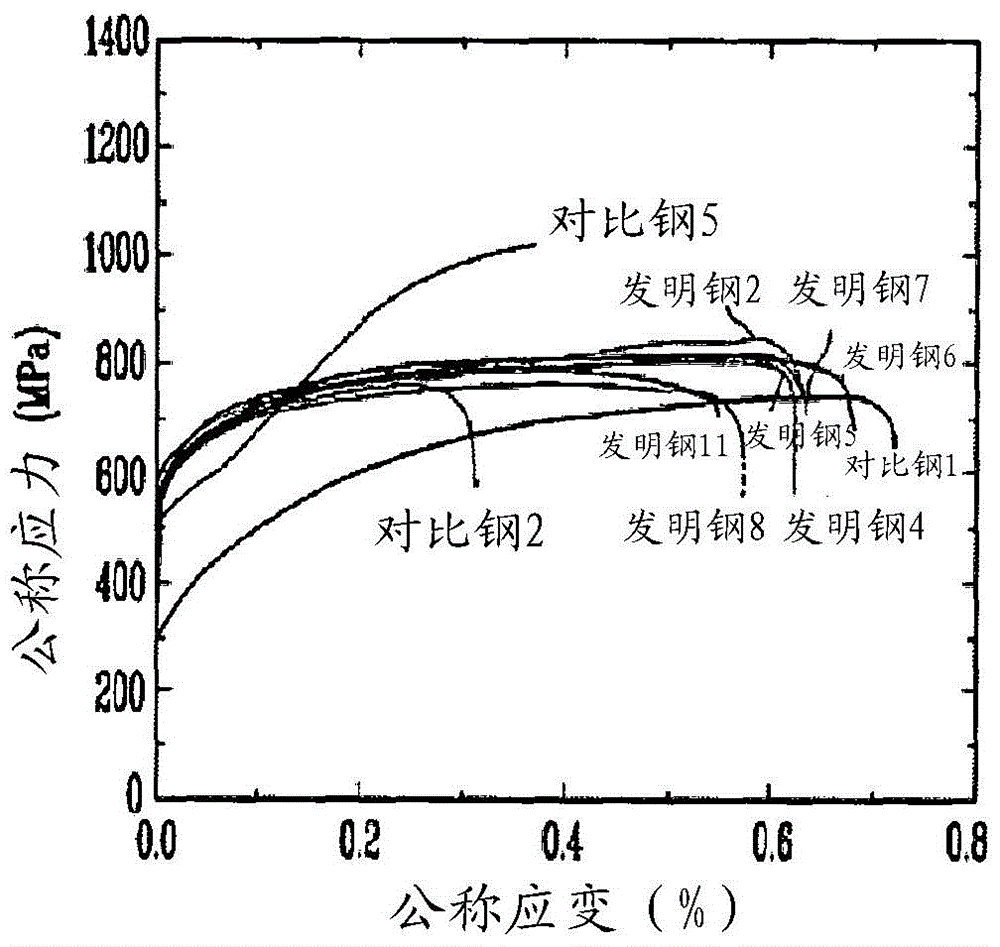

[0070] The present invention relates to an economical duplex stainless steel having a reduced content of high-valent alloying elements (such as Ni, Mo, Si, Cu, etc.) in a duplex stainless steel having two phases of austenite and ferrite. The economical duplex stainless steel can maintain the same or higher corrosion resistance than conventional austenitic-based stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com