Optical vacuum coating process

A vacuum coating and process technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating and other directions, can solve the problem of low working efficiency of optical fiber tip cleaning, affecting the quality of optical fiber line communication, and poor optical fiber positioning. It can improve the cleaning efficiency and cleaning quality, solve the problem of easy pinching and breakage of optical fibers, and solve the effects of unstable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

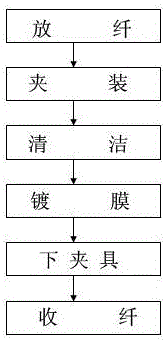

[0019] like figure 1 As shown, an optical vacuum coating process includes the following steps:

[0020] Step 1: Unwind the fiber, pull out the fiber head to be processed from the coiled fiber optic disk, keep the pulled fiber straight, and the fiber length is 10 cm;

[0021] Step 2: Clamping, embedding the released fiber head to be processed in the positioning fixture, and adjusting the clamping force of the fixture and positioning the fiber through the positioning adjustment bolt, and at least 35 fiber heads are evenly distributed on the fixture; The third step: cleaning. After the optical fiber head and the fixture are installed and positioned, the fiber head and the fixture are placed in the circulating ultrapure water for cleaning, and the cleaning solution and the fiber head are ultrasonically driven at the same time. The cleaning time is 3 minutes, and the temperature of the cleaning solution is constant at 42°C during the cleaning process;

[0022] After the cleaning ...

Embodiment 2

[0027] like figure 1 As shown, an optical vacuum coating process includes the following steps:

[0028] Step 1: Unwind the fiber, pull out the fiber head to be processed from the coiled fiber optic disk, keep the pulled fiber straight, and the fiber length is 15 cm;

[0029] Step 2: Clamping, embedding the released fiber head to be processed in the positioning fixture, and adjusting the clamping force of the fixture and positioning the fiber through the positioning adjustment bolt, and at least 35 fiber heads are evenly distributed on the fixture;

[0030] The third step: cleaning. After the optical fiber head and the fixture are installed and positioned, the fiber head and the fixture are placed in the circulating ultrapure water for cleaning, and the cleaning solution and the fiber head are ultrasonically driven at the same time. The cleaning time is 5 minutes, and the temperature of the cleaning solution is constant at 45°C during the cleaning process;

[0031] After clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com