Inspecting device of cloth inspecting machine

A technology of inspection device and cloth inspection machine, which is applied in the inspection of textile materials, textile and paper making, and marking of textile materials, etc., can solve the problems of poor cloth inspection effect, high labor intensity and low efficiency of workers, and achieve simple structure, Improve the effect of cloth inspection and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the present invention will be further explained through specific embodiments in conjunction with the drawings:

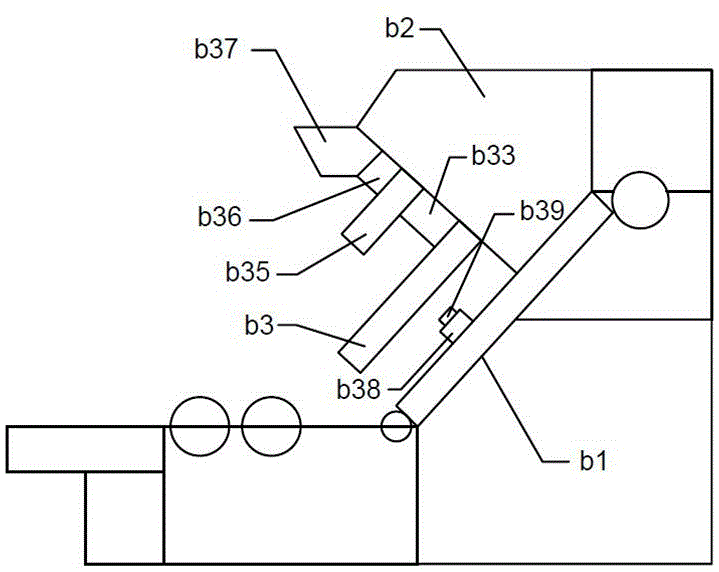

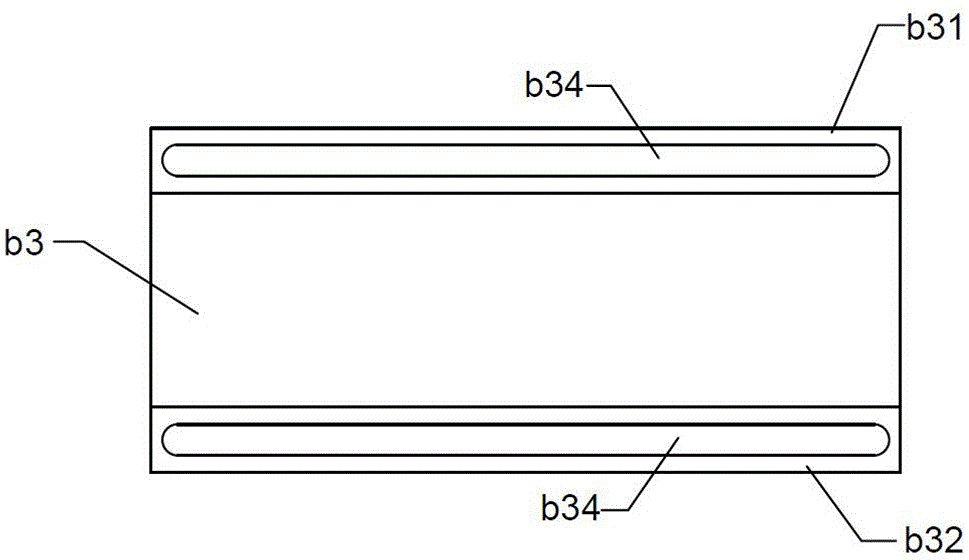

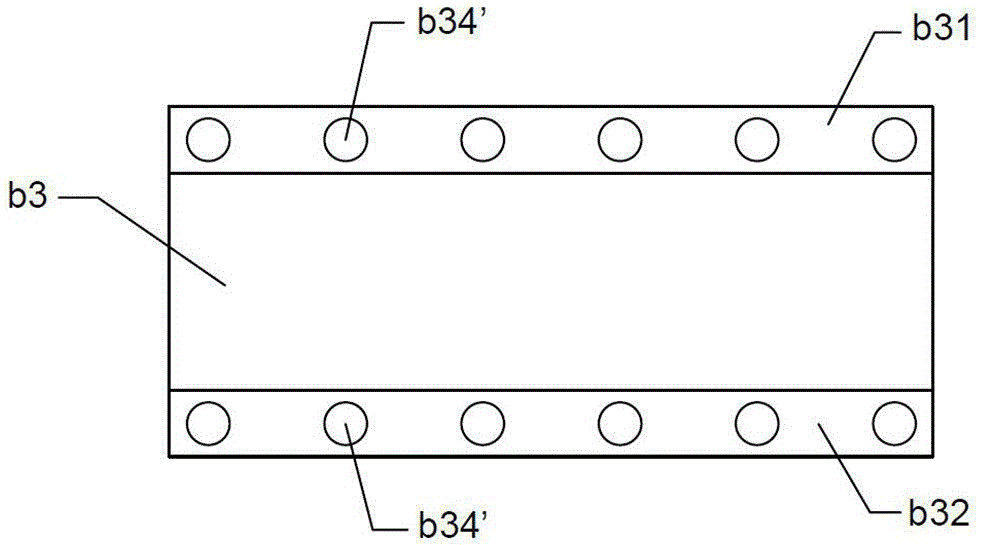

[0016] see figure 1 , figure 2 , image 3 , An inspection device of a cloth inspecting machine, comprising a body and a cloth inspection table b1 arranged on the body, and a top cover b2 arranged on the body and an observation device arranged on the top cover b2. The observation mechanism includes a cloth inspecting An observation magnifying glass b3 above the table b1 and parallel to the surface of the cloth inspection table b1, a light feeding mechanism provided on the observation magnifying glass b3, and an electronic viewfinder mechanism located above the magnifying glass b3, and a marking mechanism for cooperating with the electronic viewfinder mechanism is also provided on the body . The light-giving mechanism includes a first light-giving area b31, a second light-giving area b32 and a light distribution control for adjusting the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com