Floor-type slant-legged steel truss bracket of lower transverse beam of large-span cable tower

A large-span, floor-to-ceiling technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of difficulty in removing temporary pile caps, save construction materials and labor costs, increase overall stability, and enhance overall The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

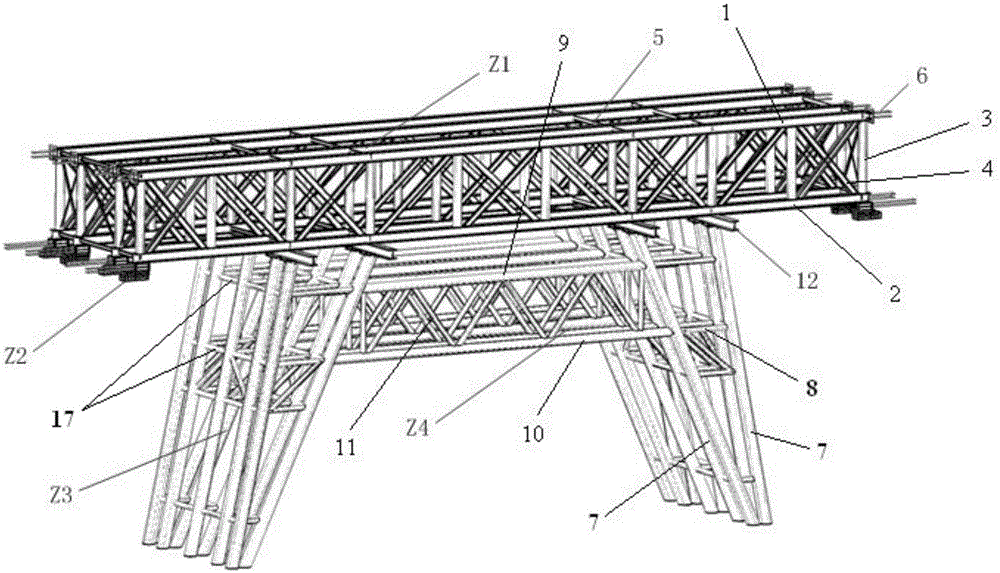

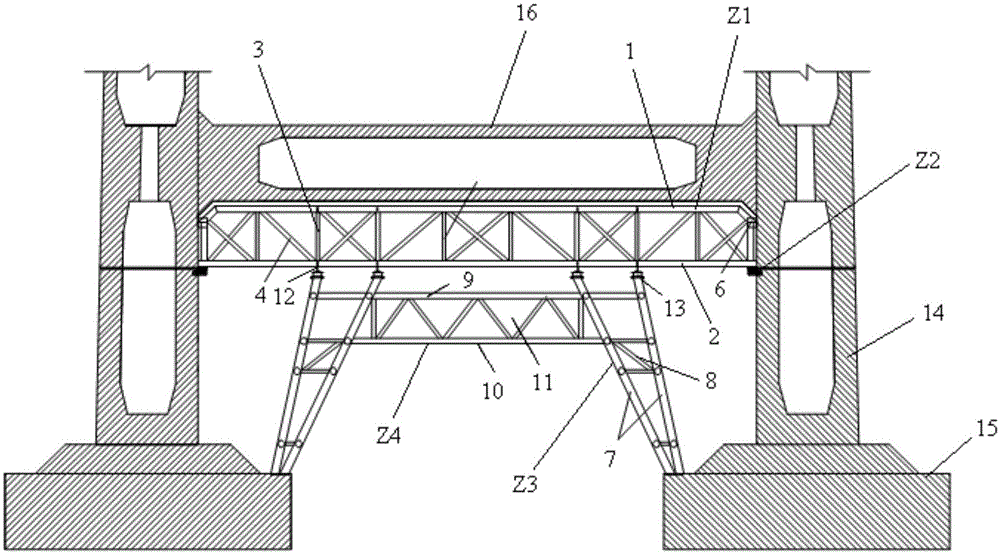

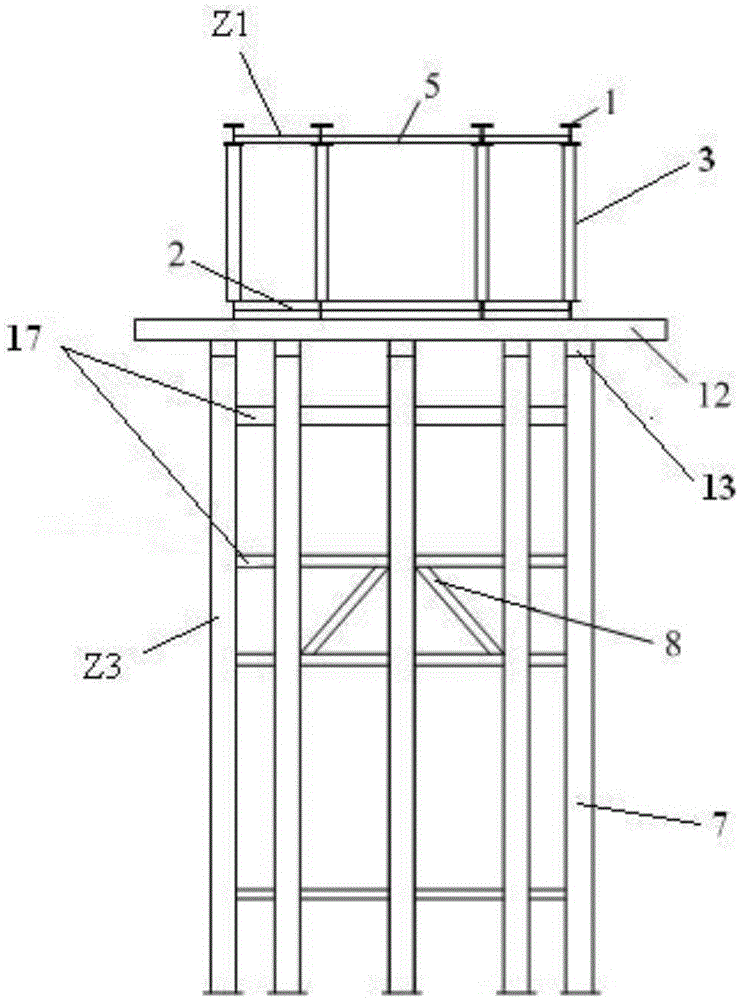

[0031] Example: Combine Figure 1~Figure 3 As shown, this large-span cable tower lower beam floor-standing inclined-leg steel truss support provided by the present invention is installed on the bottom caps 15 of tower columns 14 on both sides of the cable tower lower beam 16. Z2, oblique leg bracket Z3, anti-inclining parallel connection Z4, longitudinal distribution beam 12 and drop frame device 13 are jointly composed.

[0032] The steel truss Z1 is located below the lower beam 16 of the cable tower to bear the load of the lower beam 16 of the cable tower. The diagonal leg supports Z3 are symmetrically arranged left and right, and the bottom of each diagonal leg support Z3 is supported on the bottom of the corresponding side tower column 14. On stage 15, see for details figure 2 As shown; the top of each slant leg support Z3 is fixed with a landing gear 13, and the top of the landing gear 13 is fixed with longitudinal distribution beams 12 arranged forward and backward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com