Adjustable vortex type airflow drying oven

A vortex and airflow technology, applied in the field of vortex airflow oven, can solve the problems of poor airflow control, long drying time, and low efficiency, and achieve the effect of improving drying efficiency and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

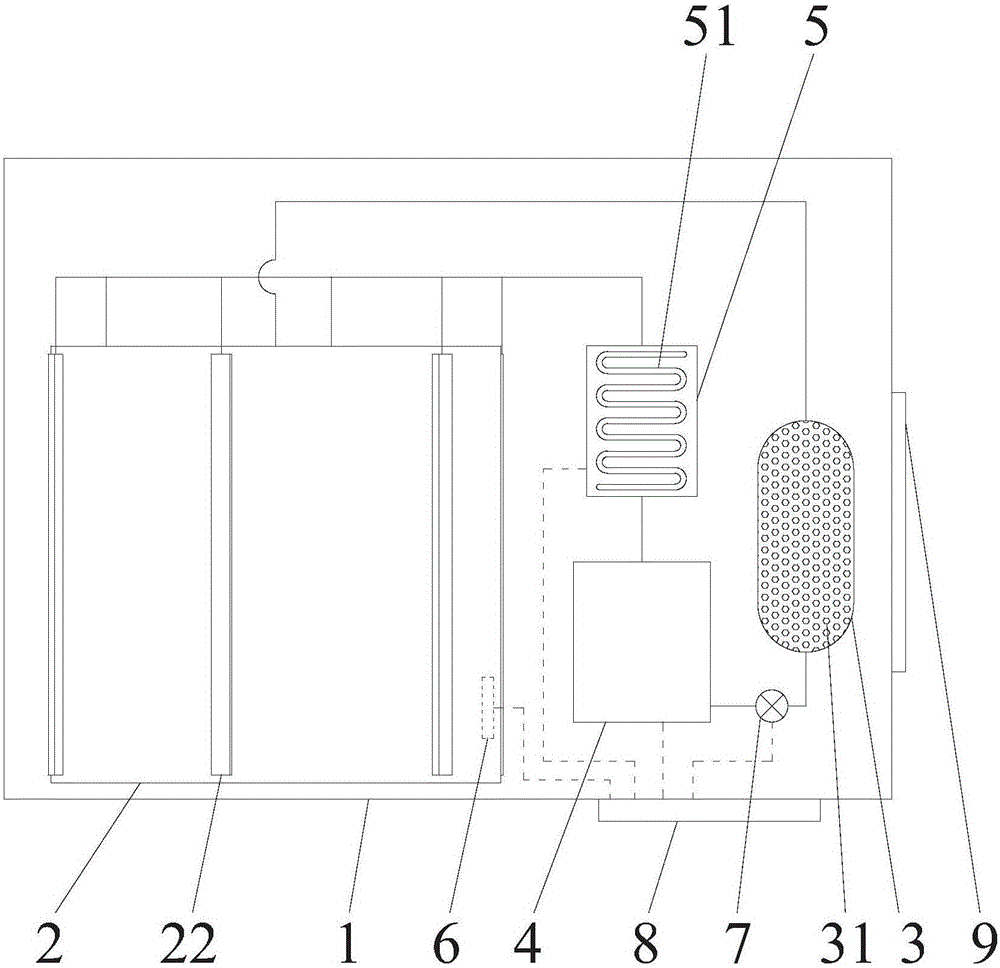

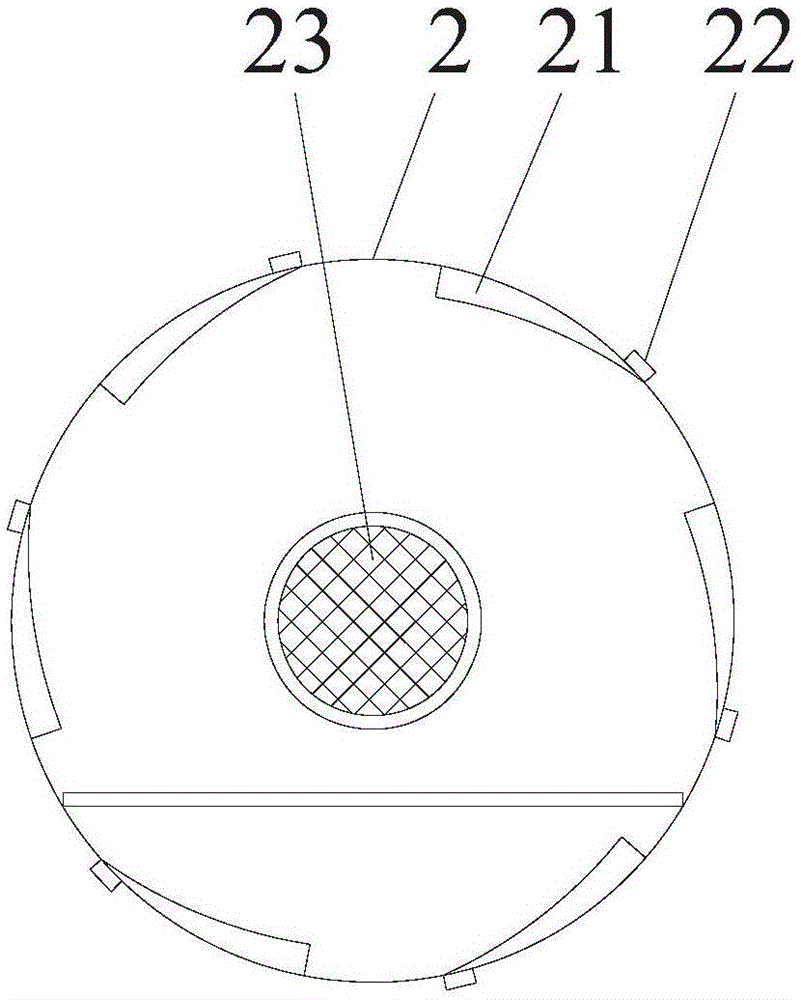

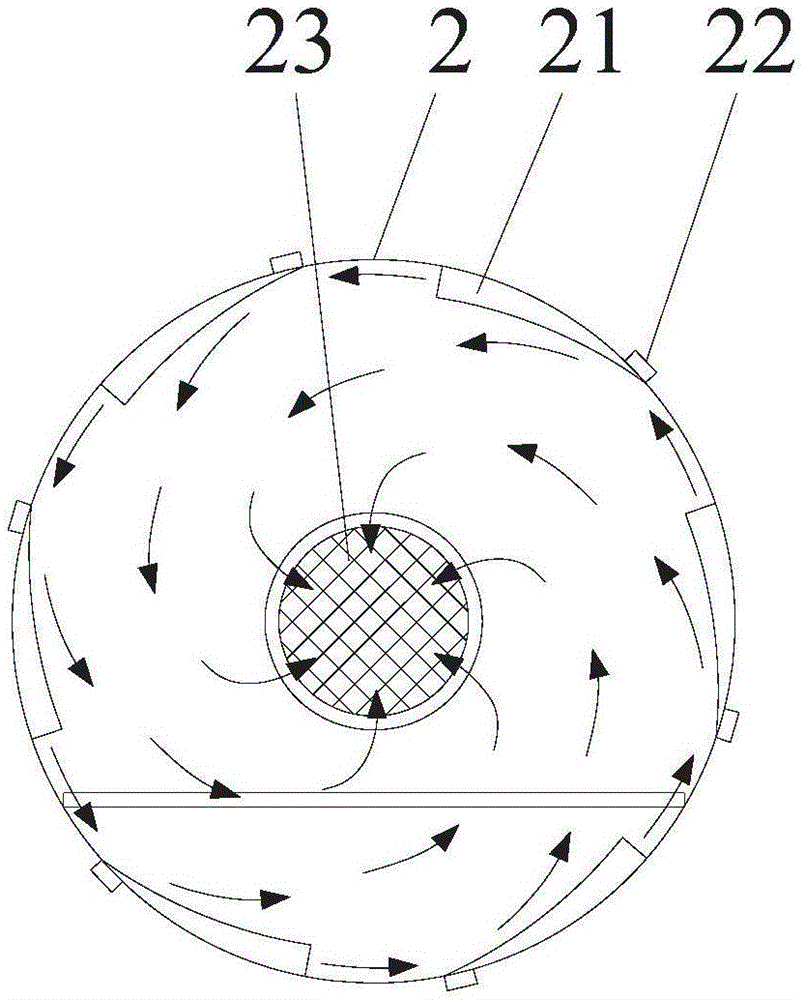

[0014] like figure 1 and figure 2 As shown, the adjustable vortex airflow oven includes a box body 1; a vortex drying chamber 2 is provided in the box body 1; the vortex drying chamber 2 is a horizontal hollow cylinder; the inner wall of the vortex drying chamber 2 There are a plurality of air injection chambers 21 arranged in a circular array; the outer wall of the air injection chamber 21 is arc-shaped; the outer wall of the vortex drying chamber 2 is provided with air injection Pipe 22; the air injection pipe 22 communicates with the air injection chamber 21; the rear side of the vortex drying chamber 2 is provided with an air outlet; the box 1 is also provided with a drying device 3, a fan 4 and a heating device 5; The air outlet is communicated with one end of the drying device 3; the other end of the drying device 3 is communicated with the air inlet of the fan 4; the air outlet of the fan 4 is communicated with one end of the heating device 5; the other end of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com