Expansion pipe for blasting and blasting method of expansion pipe

A technology for expansion tubes and main pipes, which is applied to expansion compensation devices for pipelines, blasting, pipe components, etc., can solve the problems of low cost, and achieve the effects of simple and safe operation, simple blasting preparation stage, and low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

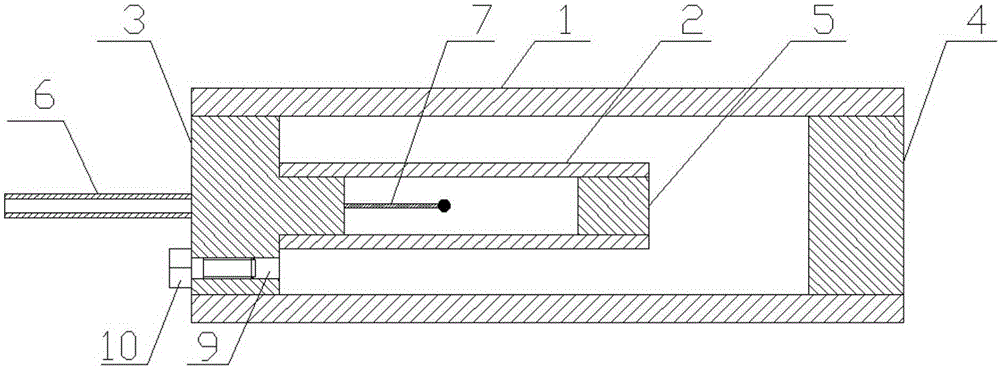

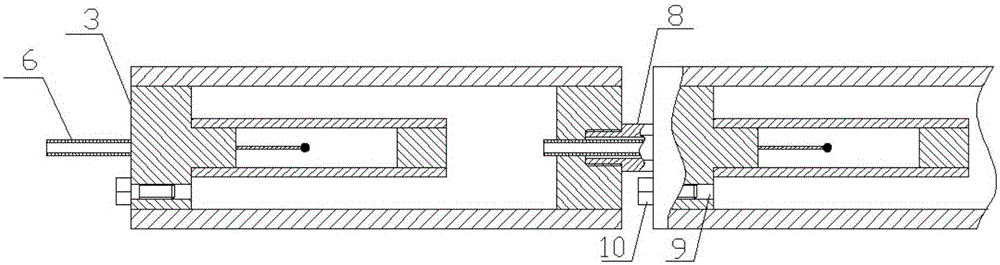

[0030] Example 1, such as figure 1 with figure 2 As shown, the main pipe 1, the branch pipe 2, the first plug 3, the second plug 4 and the sealing plug 5 of the expansion pipe are all made of PVC material, the connecting pipe 6 is made of metal material, and the gasification agent in the branch pipe 2 is made by mass Proportioning comprises respectively the nitroguanidine of 45%, the basic copper nitrate of 45%, the ferric oxide of 5% and the ammonium perchlorate of 5%, the length of every expansion pipe is 80cm, and diameter is 90mm, utilizes above-mentioned The blasting method of the structural expansion tube specifically includes the following steps:

[0031] a. Connect a group of expansion tubes end to end and fix them. The two adjacent expansion tubes are fixedly connected by a fixing piece 8. The fixing piece 8 is a pipe fitting with external threads at both ends and a hexagonal prism structure in the middle. Both the first plug 3 and the second plug 4 of the tube are...

Embodiment 2

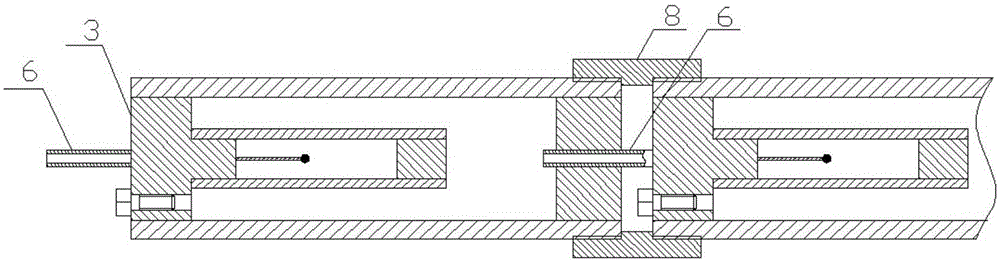

[0035] Example 2, such as figure 1 with image 3 As shown, the main pipe 1, the branch pipe 2, the first plug 3, the second plug 4 and the sealing plug 5 of the expansion pipe are all made of PVC material, the connecting pipe 6 is made of metal material, and the gasification agent in the branch pipe 2 is made by mass Proportioning comprises respectively the nitroguanidine of 45%, the basic copper nitrate of 45%, the ferric oxide of 5% and the ammonium perchlorate of 5%, the length of every expansion pipe is 80cm, and diameter is 90mm, utilizes above-mentioned The blasting method of the structural expansion tube specifically includes the following steps:

[0036]a. Connect a group of expansion tubes end to end and fix them. The two adjacent expansion tubes are fixedly connected by a fixing piece 8. The fixing piece 8 is a pipe fitting with internal threads at both ends. The head and tail of the expansion tubes are fixed. External threads are provided, and the threads at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com