A holographic detection method for shape and position error of high-precision static pressure guide rail

A technology of shape and position error and static pressure guide rail, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of low detection accuracy and insufficient data resolution, and achieve high detection accuracy and high-precision detection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0029] The holographic detection method for the shape and position error of a high-precision static pressure guide rail proposed by the present invention is not limited to the measurement of the static pressure guide rail. For prism parts, after the surface to be measured is polished by optical processing means, high-precision holographic error distribution data can be obtained by this method. The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

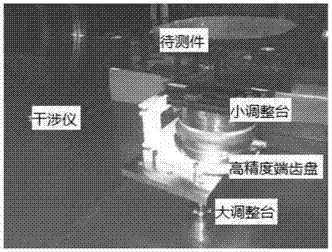

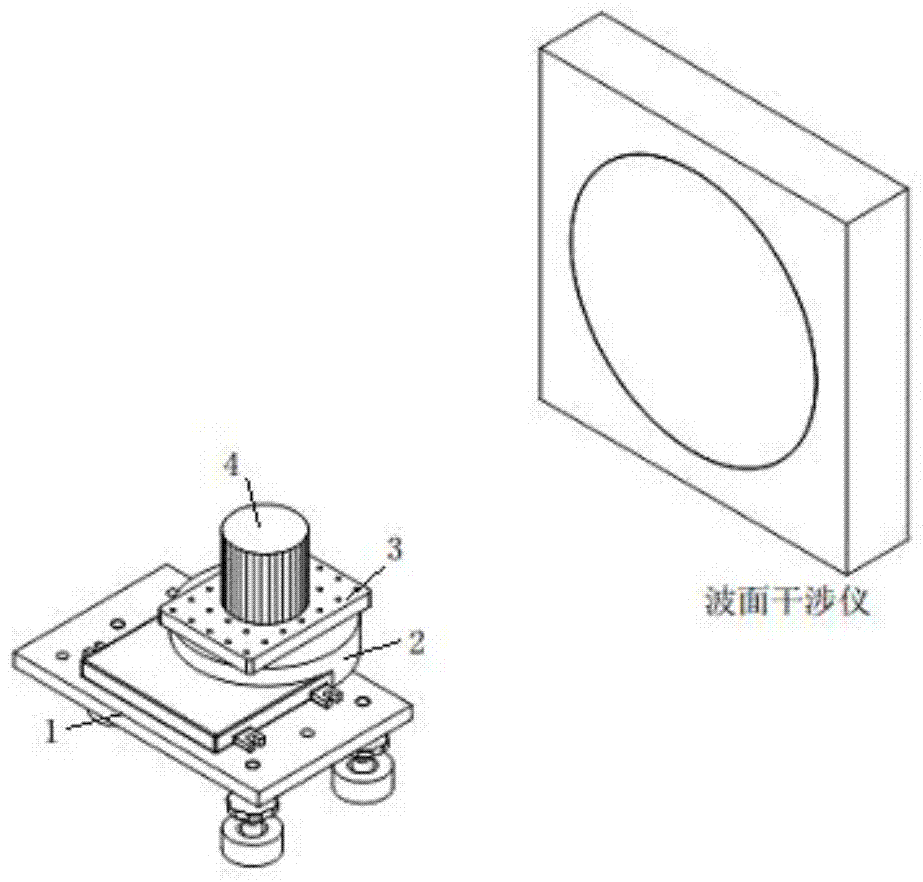

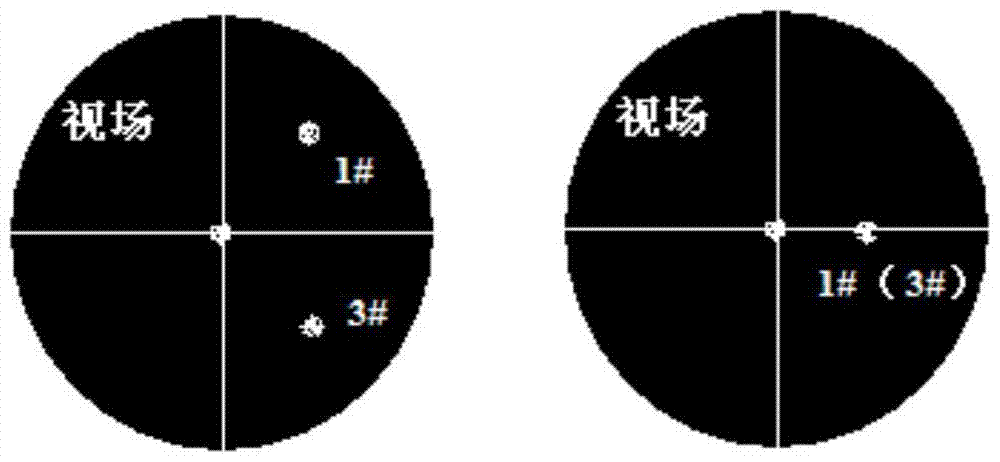

[0030] Such as image 3 As shown, the test piece is a cuboid part, and the position accuracy index between the four sides is 2 ". The process of obtaining the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com