LED display screen field testing apparatus and method

A technology for LED display and on-site testing, applied in the direction of testing optical performance, etc., can solve the problems of inconsistent installation environment of LED display, not representing the overall performance of LED display, inconvenient testing, etc. The effect of fast handling and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

[0028] The LED display field testing device described in this embodiment includes hardware and software:

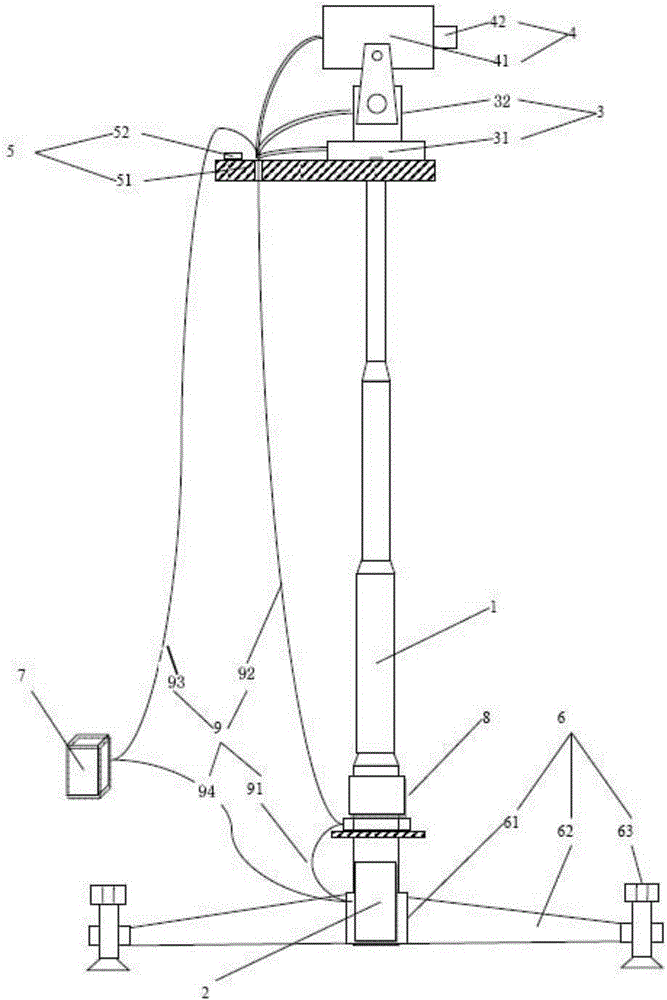

[0029] Such as figure 1 , 2 , the hardware part includes a pneumatic lifting rod 1, an air pump 2, an optical test device 4, a reference platform 5, a fixed base 6, a portable power supply 7, a computer 8 and a three-dimensional rotating platform 3 with a driving device, such as figure 1 As shown, wherein, the pneumatic lifting rod 1 is installed vertically and detachably on the fixed base 6, and is driven by the air pump 2 to realize free expansion and contraction; the reference platform 5 is horizontally and detachably installed on the top of the pneumatic lifting rod 1, through Adjust the adjustment balance stud 502 of the fixed base 6 to adjust the levelness of the reference platform 5, to ensure that the lower surface of the three-dimensional rotating platform 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com