Flexible eddy current sensor for curved surface part defect detection

An eddy current sensor and sensor technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as low detection efficiency, reduce lift-off noise, and overcome sensitivity problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

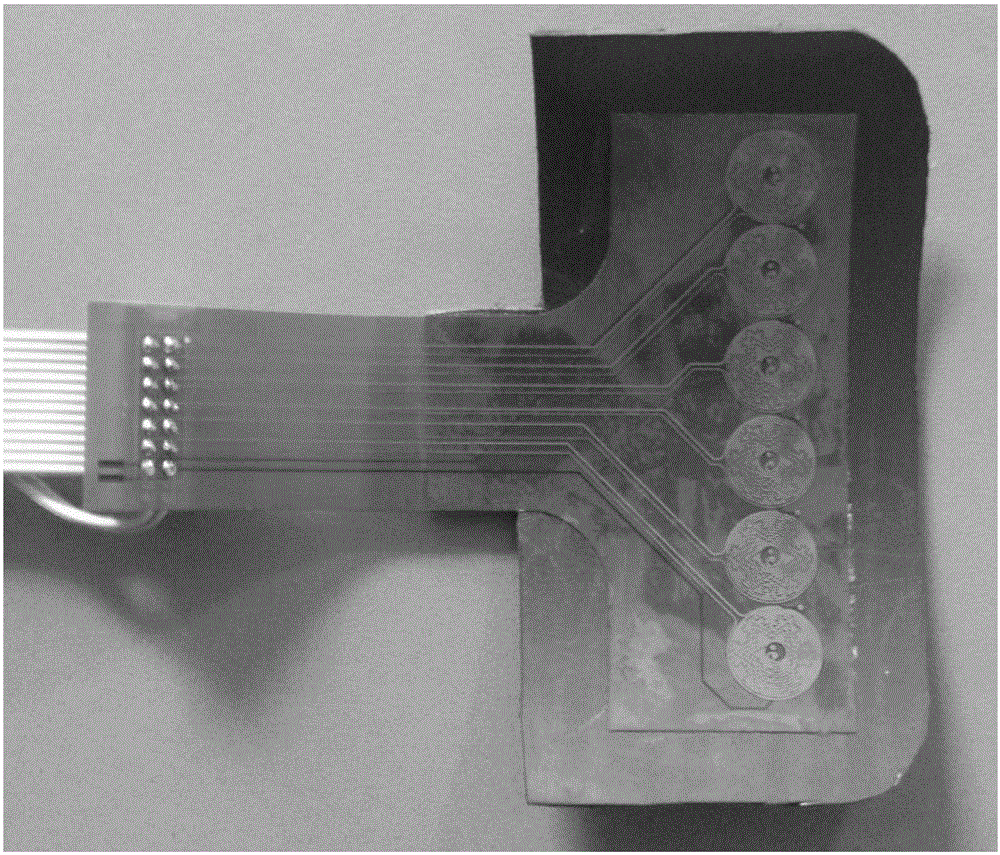

[0018] In the embodiment, a ferromagnetic curved metal member is selected, and the crack-like defects with the size of (width × length × depth) 0.15mm × 20mm × 1mm are processed by electric spark etching on it, such as Figure 5 As shown, the surface was chosen to verify the adsorption capacity of the sensor. Move the sensor along the axis of the specimen. It can be seen from the imaging picture that the highlighted part is the position of the crack. In this embodiment, only a test piece of ferromagnetic material is tested. The invention can detect a variety of ferromagnetic conductive materials, and the number of coil turns and wire diameter of the sensor can be adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com