Automatic low resistance test device

A test device and low-resistance technology, which is applied in the direction of measuring device, measuring resistance/reactance/impedance, measuring electrical variables, etc. problems, to achieve the effect of improving test reliability, high test efficiency and easy reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

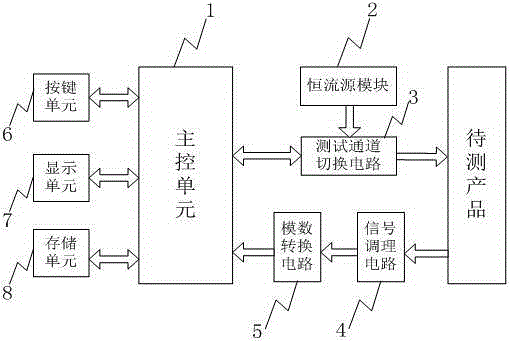

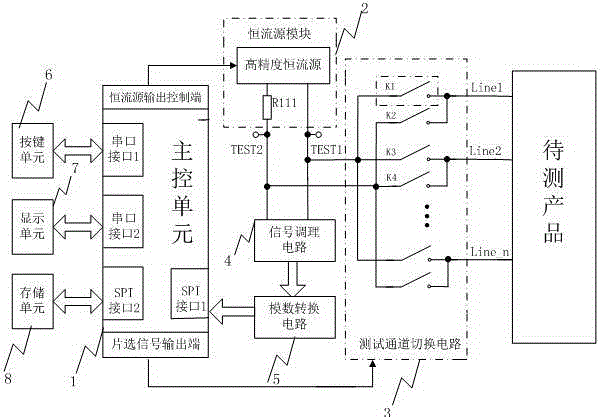

[0036] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings. An automatic low resistance test device such as figure 1 with 2 As shown, it includes a main control unit 1 , a constant current source module 2 , a test channel switching circuit 3 , a signal conditioning circuit 4 , an analog-to-digital conversion circuit 5 , a key unit 6 , a display unit 7 and a storage unit 8 .

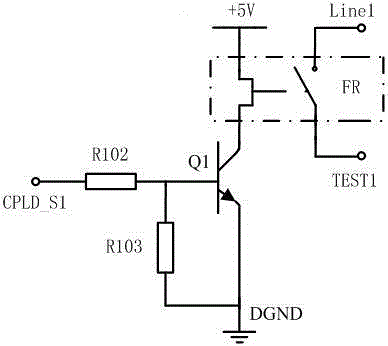

[0037] The test channel switching circuit 3 is composed of a CPLD and a switch module, and each lead wire of the product is respectively connected to the positive test point TEST1 and the negative test point TEST2 through two switch modules. The switch module structure is as image 3 As shown, the module includes a transistor Q1, a resistor R101, a resistor R102 and a normally open relay FR. When the corresponding driving signal CPLD_S1 is at high level, the transistor Q1 is turned on, and the relay is closed due to the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com