Centralized control system for industrial microwave power source

A technology of industrial microwave power supply and centralized control system, applied in general control system, control/regulation system, program control and other directions, can solve the problems of inability to monitor the working state of microwave power supply in real time, and inability to adjust power, and achieve timely problems and equipment maintenance. Convenient and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

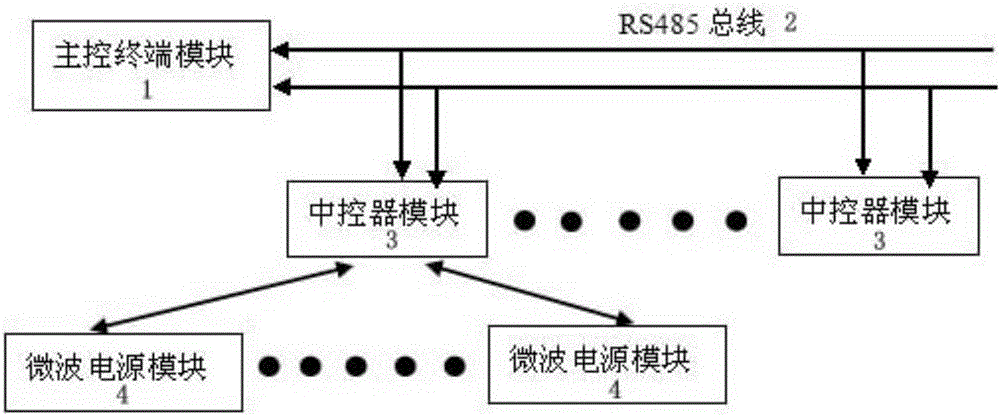

[0018] Such as figure 1 As shown, the present embodiment includes several microwave power supply modules 4, and the microwave power supply modules 4 are controlled and monitored by a control system. The control system includes a main control terminal module 1 and several central controller modules 3. The main control terminal module 1. It has a control input terminal and an operation / monitoring panel structure. The detection signal input terminal of the central controller module 3 is connected to the signal output terminal of the microwave power supply module 4, and the control signal output terminal is connected to the control signal input terminal of the microwave power supply module 4. The central controller The control signal input terminal and feedback signal output terminal of module 3 are connected to the I / O port of main control terminal mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com