Passive ultrahigh-frequency RFID tag for temperature alarming

A RFID tag and ultra-high frequency technology, applied in the field of passive ultra-high frequency RFID tags, can solve the problems of coil short circuit, high price of electronic tags, high cost of tags, etc., and achieve good impedance matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the accompanying drawings.

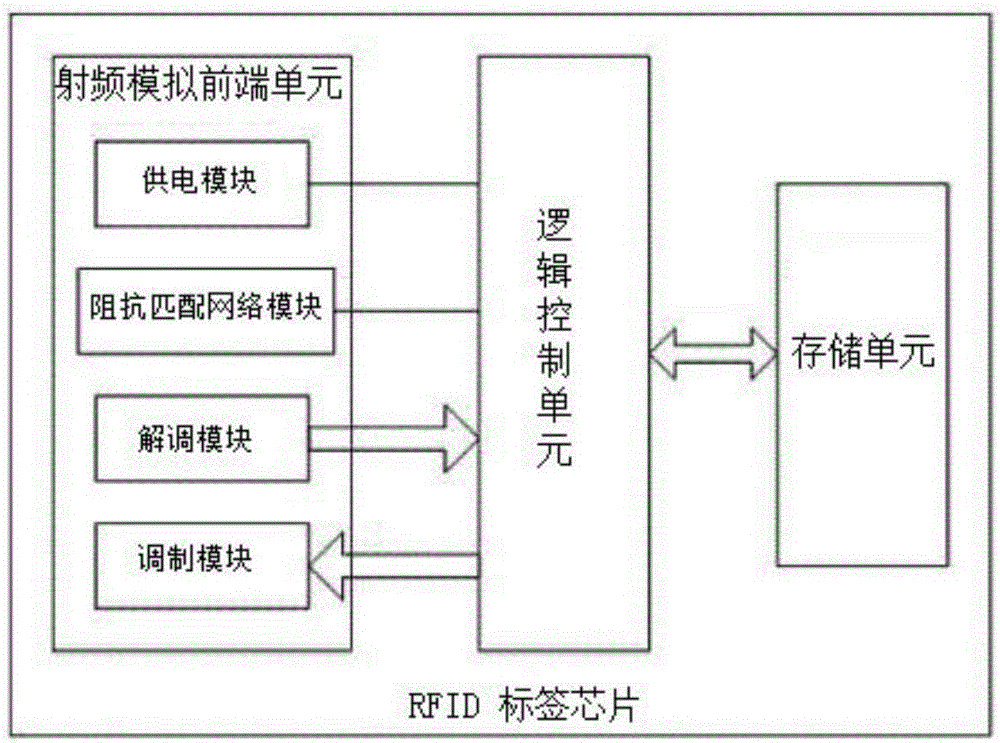

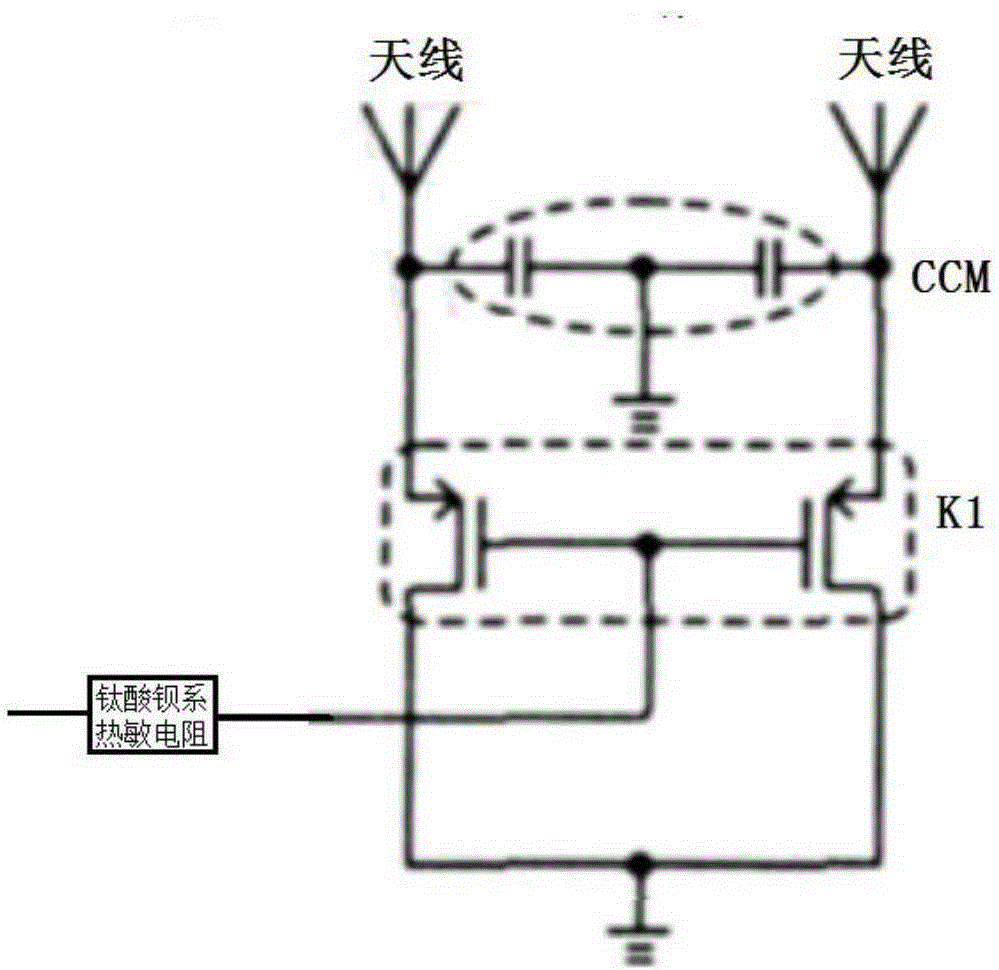

[0012] like figure 1 As shown, a passive ultra-high frequency RFID tag used for temperature alarm includes a tag chip and a tag antenna connected with the tag chip. The tag chip includes a radio frequency analog front-end unit, a logic control unit, and a storage unit that are connected in sequence. The RF analog front-end unit includes a power supply module, an impedance matching network module, a demodulation module and a modulation module respectively connected to the logic control unit. The impedance matching network module includes a first capacitor, a second capacitor, a first PMOS switch tube, a second PMOS switch tube, and a barium titanate thermistor. The first capacitor and the second capacitor are connected in parallel between the tag antenna and the ground; the gates of the first PMOS switch tube and the second PMOS switch tube are connected to the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com