Heat-engine plant grinding machine load prediction method based on periodic rolling optimization

A rolling optimization and load forecasting technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as difficulty in predicting mill load in thermal power plants and reducing model forecasting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

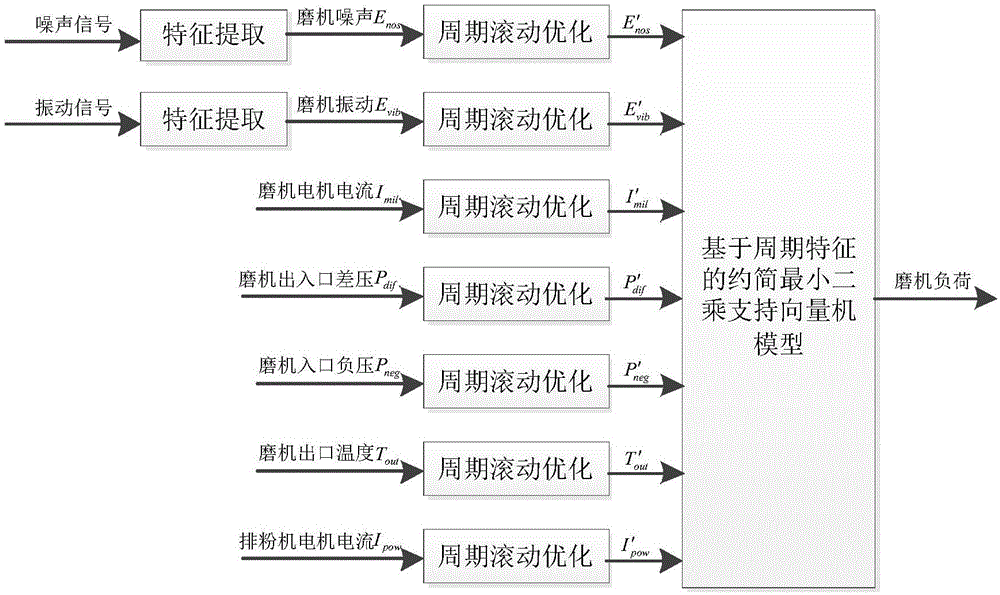

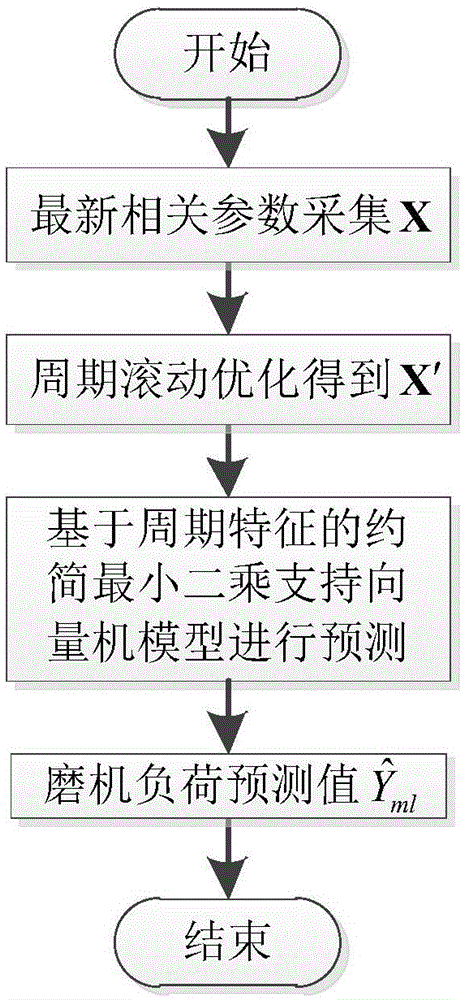

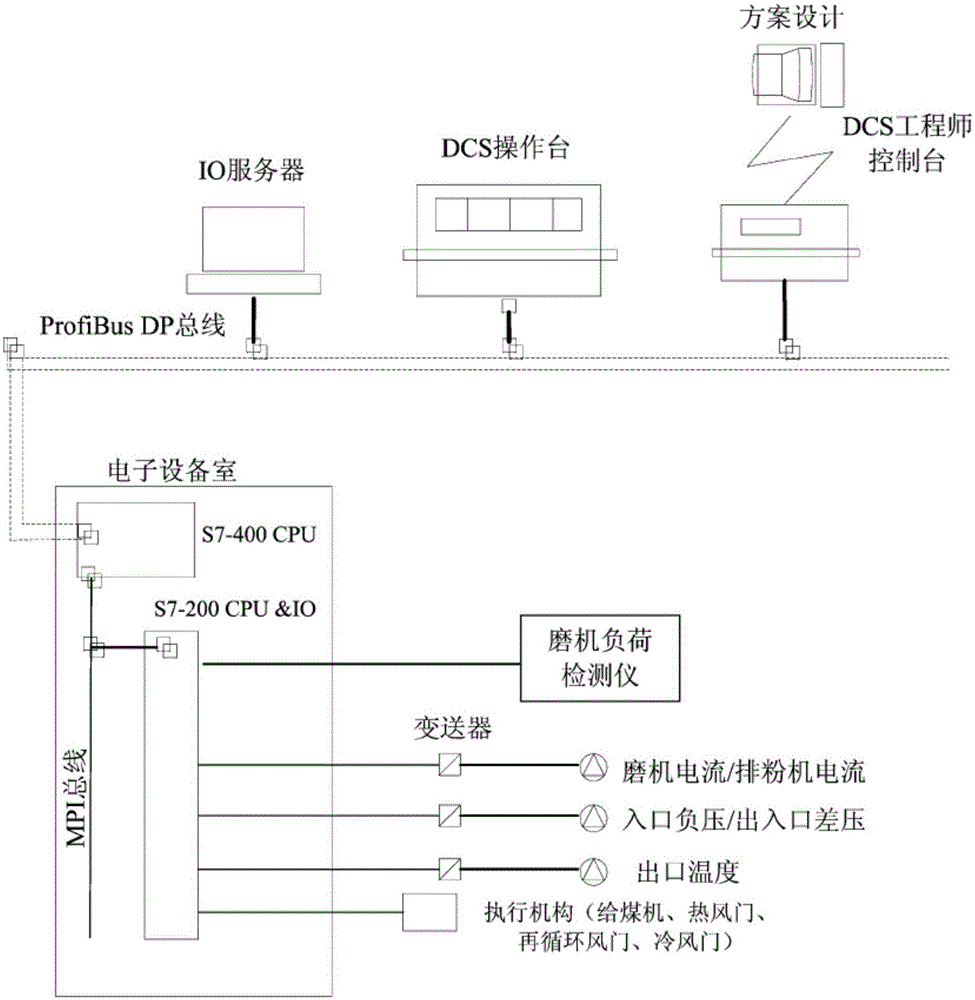

[0041] The block diagram of the thermal power plant mill load prediction method based on periodic rolling optimization of the present invention is as follows figure 1 As shown, the flow chart is as figure 2 shown. Taking a mill in a thermal power plant as an example, a specific application of the present invention is given. The mill model is DTM350 / 700, and the speed is 17.57r / min. DCS is used to realize the collection of mill input signals, the execution of algorithms, and other various operation monitoring functions. The system structure is as follows: image 3 shown. In the real-time control layer, it is composed of Siemens S7-400 and S7-200 series PLCs and their extended input and output modules, making full use of the advantages of S7-200 series PLCs such as low cost, easy expansion, and simple programming to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com