Method for realizing yield increase of flue-cured tobacco through densely-sown seedling raising and optimized transplanting

A technology for transplanting small seedlings and flue-cured tobacco, which is applied in the field of flue-cured tobacco cultivation, can solve the problems of transplanting and failure of spring dry tobacco seedlings, and achieve the effects of early transplanting, reducing the transmission of diseases and insect pests, and increasing the yield of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

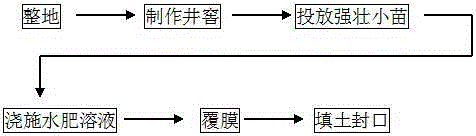

[0016] Embodiment: In February 2012, in Qinglong County, Qianxinan Autonomous Prefecture, Guizhou Province, the dense sowing of flue-cured tobacco seedlings was selected, and the tobacco seedlings were cultivated by the floating plate dense sowing method, and the rainwater storage ponds were used to store water to resist spring drought, and the well pit type seedlings were transplanted. To enable tobacco seedlings to be transplanted at a suitable time, the specific method is: use 595-hole floating trays to raise seedlings, cultivate for about 35 days, and form tobacco seedlings with 4 leaves and a core of tobacco age, and start to use the method of transplanting seedlings under the film to be planted; Deep plowing began in February, soil preparation began in March, stripping and ridges for planting began in early April, and transplanting began around April 20 to make well cellars and lift up the healthy and healthy four-leaf single-hearted tobacco seedlings vertically Put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com