Brewing mechanism of capsule coffee machine

A coffee machine and brewing technology, applied in the field of brewing mechanism, can solve the problems of long coffee consumption, light taste, slow dissolution speed, etc., and achieve the effect of simple implementation, uniform dissolution speed and large water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

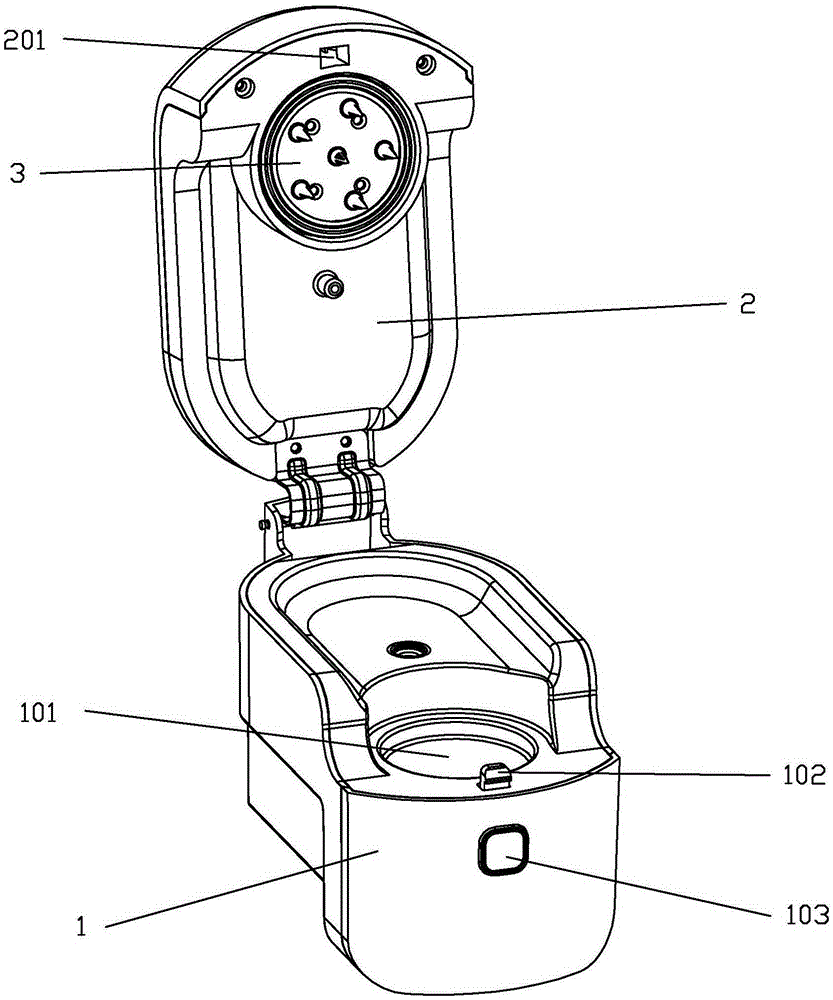

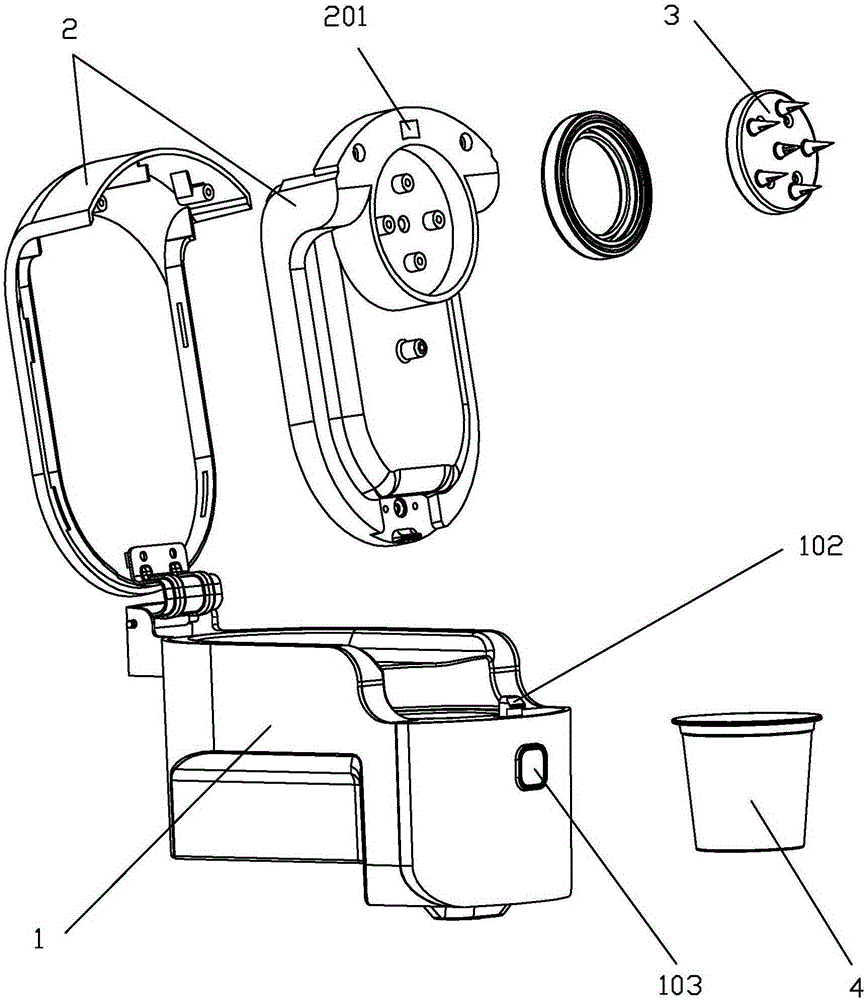

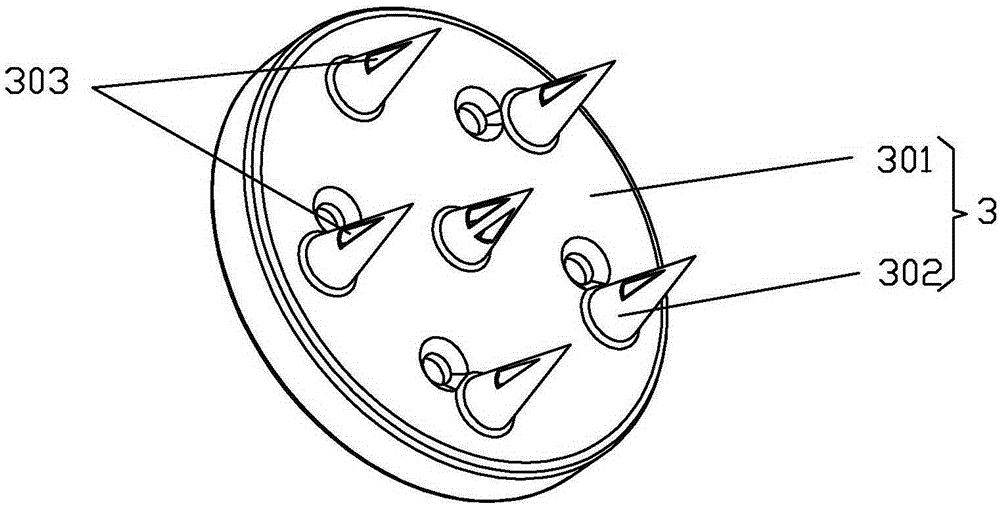

[0017] refer to Figure 1~Figure 5 , a brewing mechanism of a capsule coffee machine, comprising a brewing seat 1 and a flip cover 2, the brewing seat 1 is provided with a brewing cup 101 for accommodating capsules, and the bottom of the brewing cup 101 is provided with a piercing device 5 , the flip cover 2 is hinged to one end of the brewing seat 1, the flip cover 2 is connected with a piercing device 3 corresponding to the position of the brewing cup 101, and the piercing device 3 includes a disc-shaped water inlet tray 301 and an inlet A plurality of piercing needles 302 arranged on the water tray 301, the piercing needles 302 are provided with a water hole 303 connected to the water inlet tray, the center of the water inlet tray 301 is provided with a piercing needle 302, and the piercing needles 302 are provided with Four water holes 303. With the above structure, the coffee capsule 4 is put into the brewing cup 101, and then the flip cover 2 is turned and pressed onto ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com