Planetary stirring device for instant noodles

A technology for planetary stirring and instant noodles, which is applied to mixers with rotary stirring devices, chemical instruments and methods, and directions such as dissolving, can solve the problems of insufficient stirring, small stirring range, poor taste of instant noodles, etc., and achieves high stirring efficiency. Good stirring effect and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

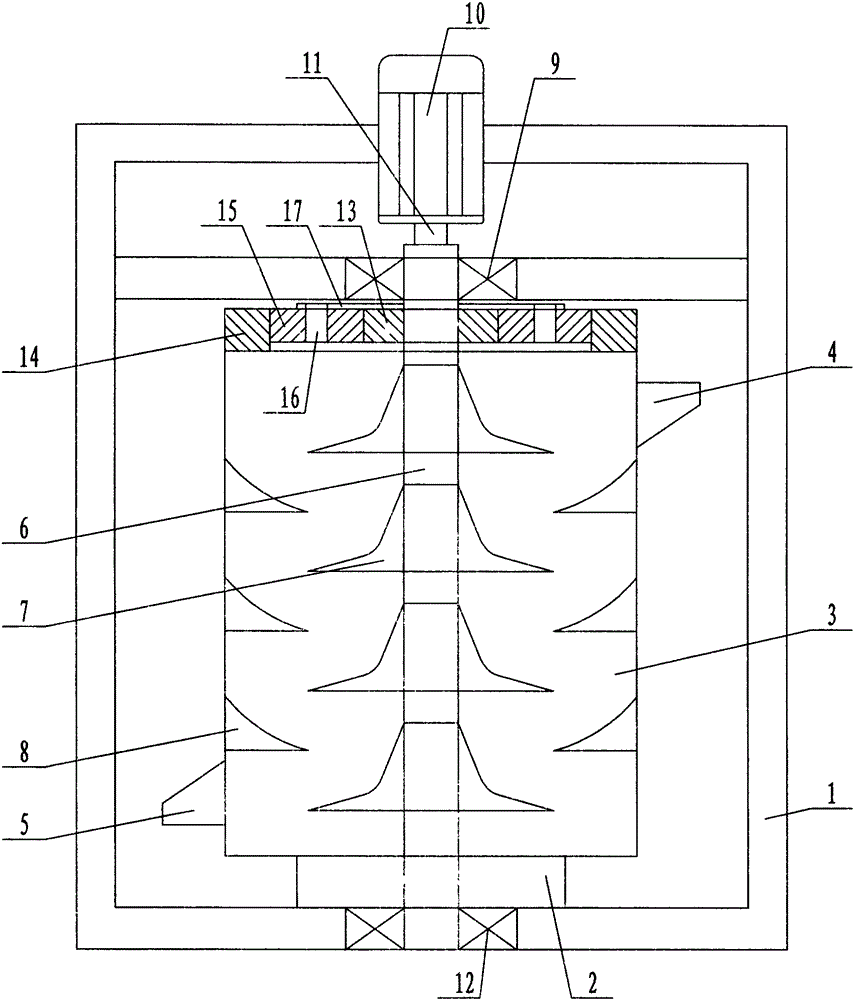

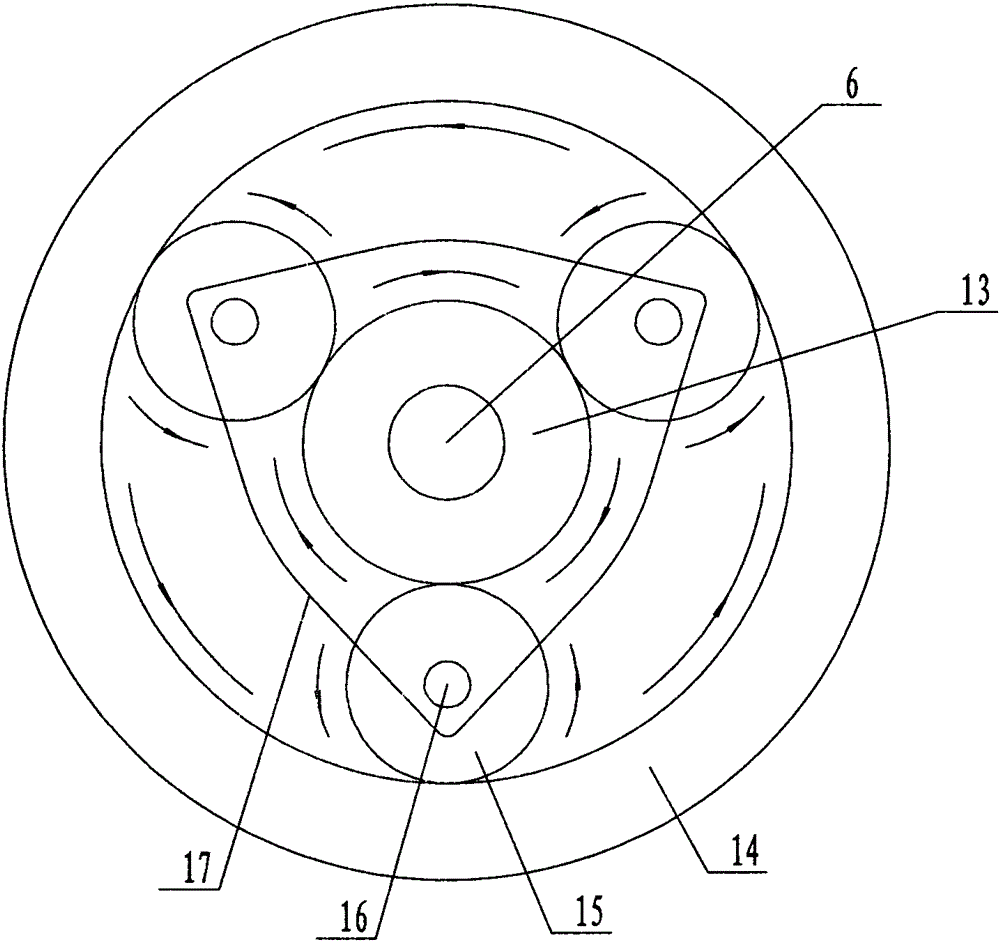

[0010] The specific content of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0011] like figure 1 , figure 2 As shown, the instant noodle planetary stirring device includes: a frame 1, a turntable 2 is rotatably arranged at the lower end of the frame 1, a mixing drum 3 is rotatably arranged on the turntable 2, and a side of the mixing drum 3 is rotatably arranged The upper end is provided with a feeding port 4, the lower end of the other side of the stirring drum 3 is provided with a discharging port 5, a stirring shaft 6 is provided in the stirring drum 3, and several The active stirring blades 7 are evenly provided with a number of driven stirring blades 8 inside the stirring drum 3, the active stirring blades 7 and the driven stirring blades 8 are alternately arranged, and the upper end of the stirring shaft 6 extends out of the stirring drum 3 The upper bearing seat 9 is rotatably arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com