Aggregate distribution box system

A cloth box and aggregate technology, applied in the field of brick cloth box system, can solve the problems of excessive accumulation of aggregates, insufficient moisture in aggregates, affecting strength, etc., and achieve the effect of preventing uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

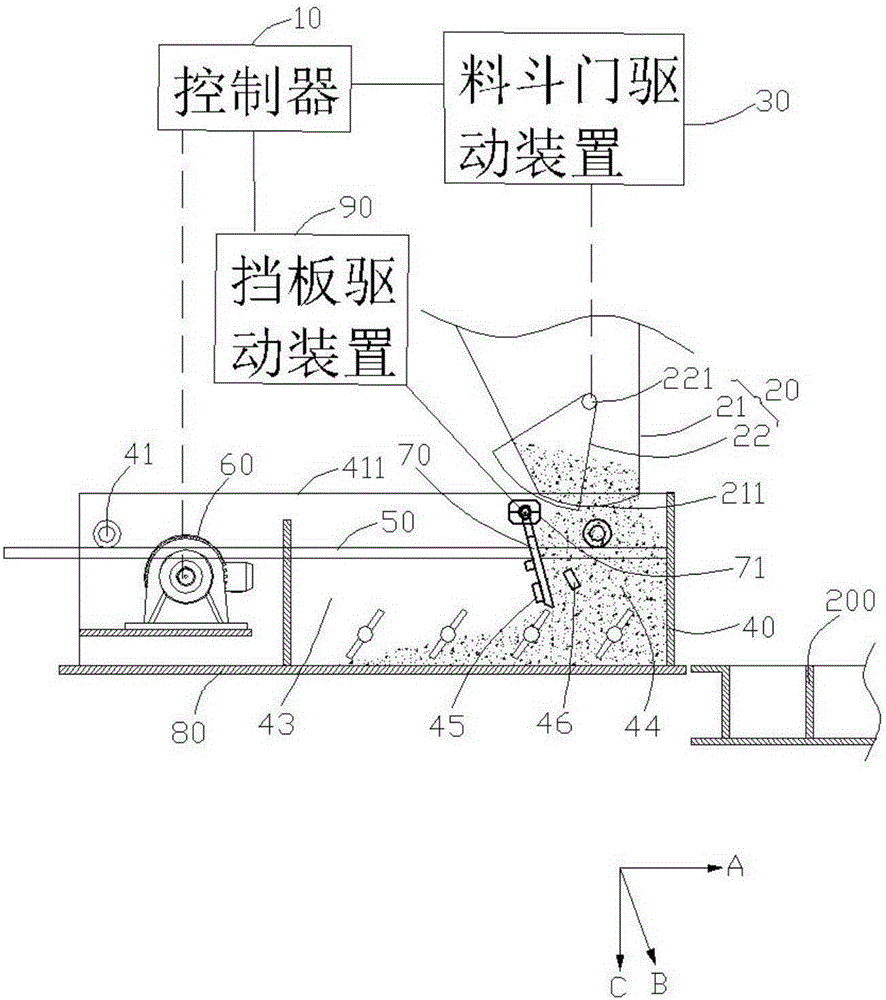

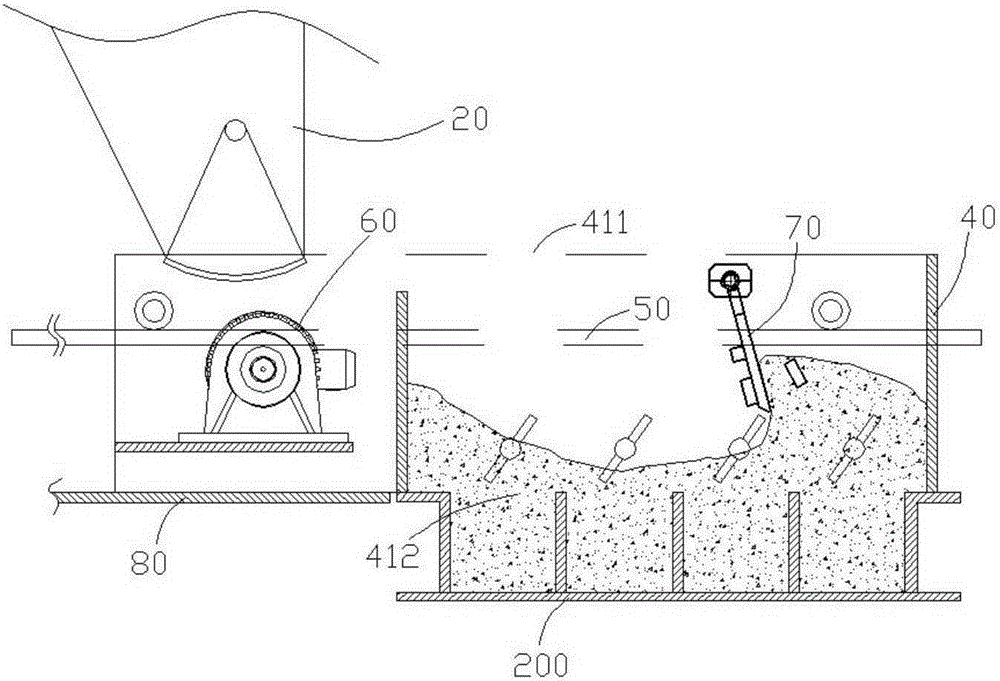

[0017] The distribution box system provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] see figure 1 and figure 2 , in a preferred embodiment of the present invention, a distribution box system is used to distribute materials in a brick mold 200, and includes a controller 10, a hopper 20, a hopper door driving device 30, a distribution box 40, A guide rail 50 , a distribution box driving device 60 , a baffle plate 70 , a barrier plate 80 and a baffle plate driving device 90 .

[0019] The hopper 20 is located above the distribution box 40 for containing aggregates, and includes a hopper body 21 and a hopper door 22 . The bottom of the hopper body 21 is provided with a discharge port 211 for discharging aggregate; the hopper door 22 is rotatably mounted on the hopper body 21 to open or close the discharge port 211, further, The hopper door 22 is mounted on the hopper body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com