Automatic insert injection molding machine

An injection molding machine and insert technology, applied in the field of automatic insert injection molding machines, can solve the problems of complex operation in the production process, many abnormal situations, and easily damaged molds, etc., to achieve the same quality, avoid danger, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

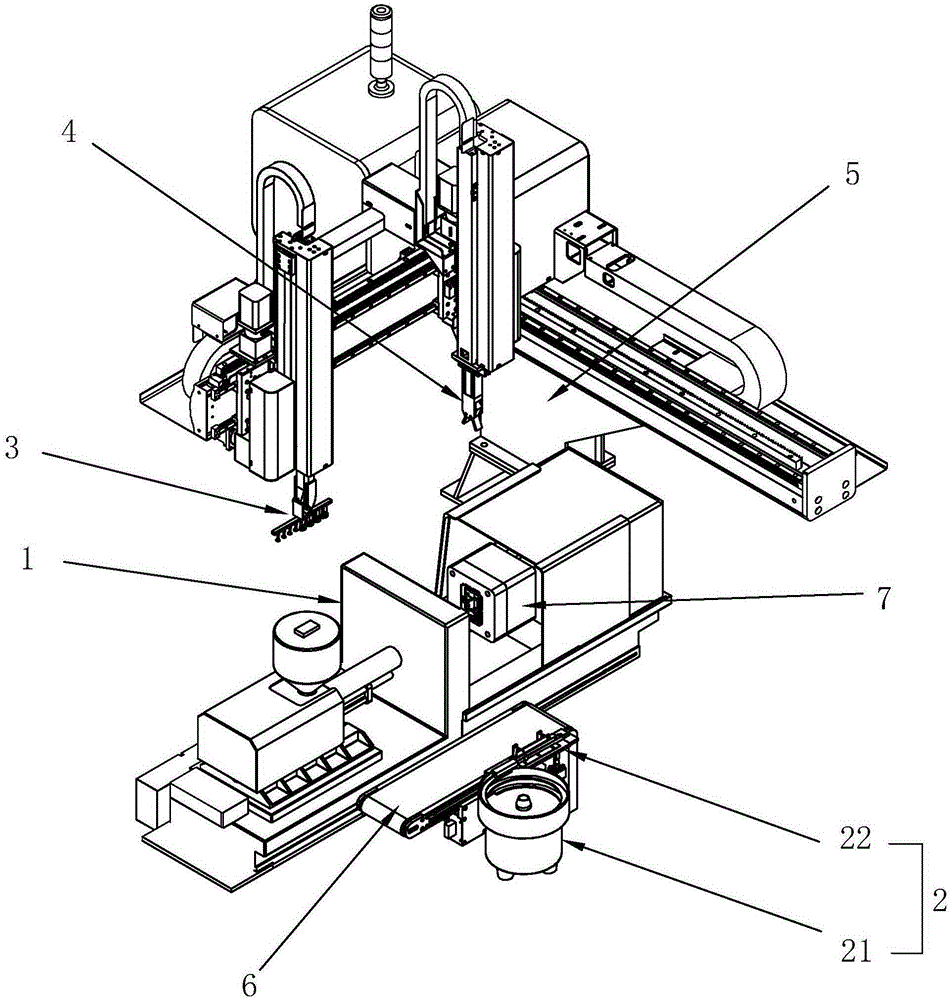

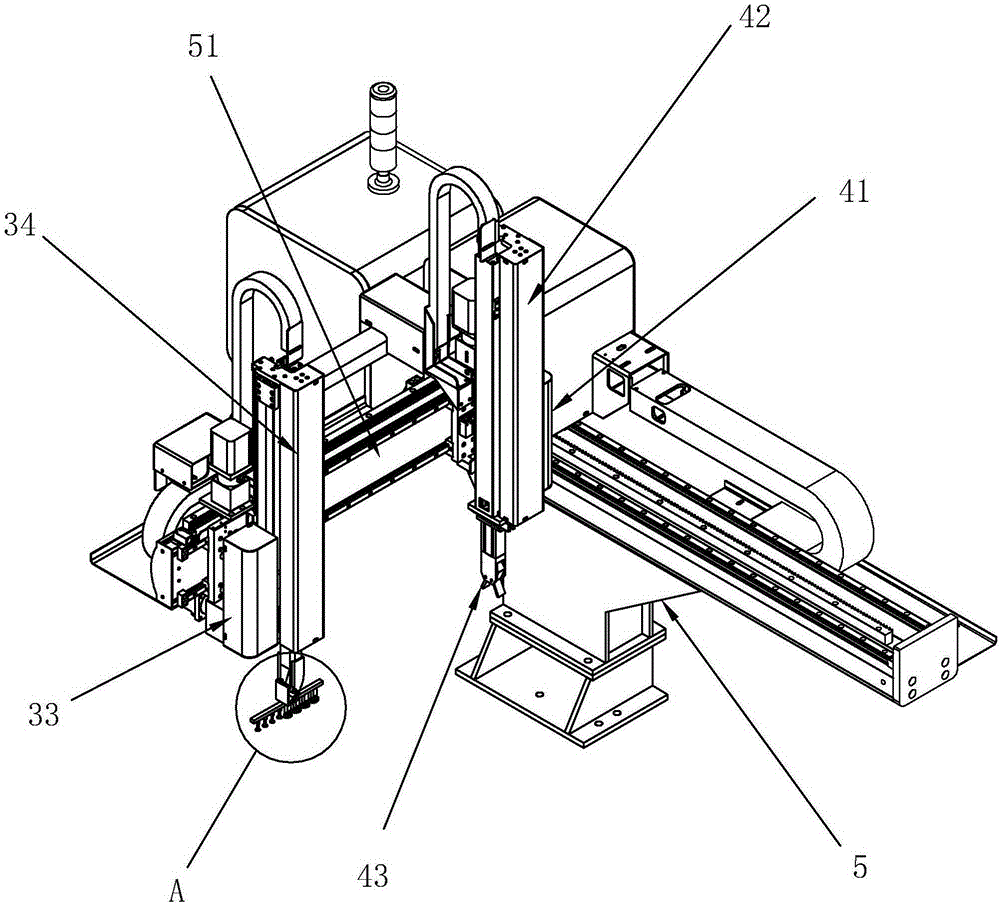

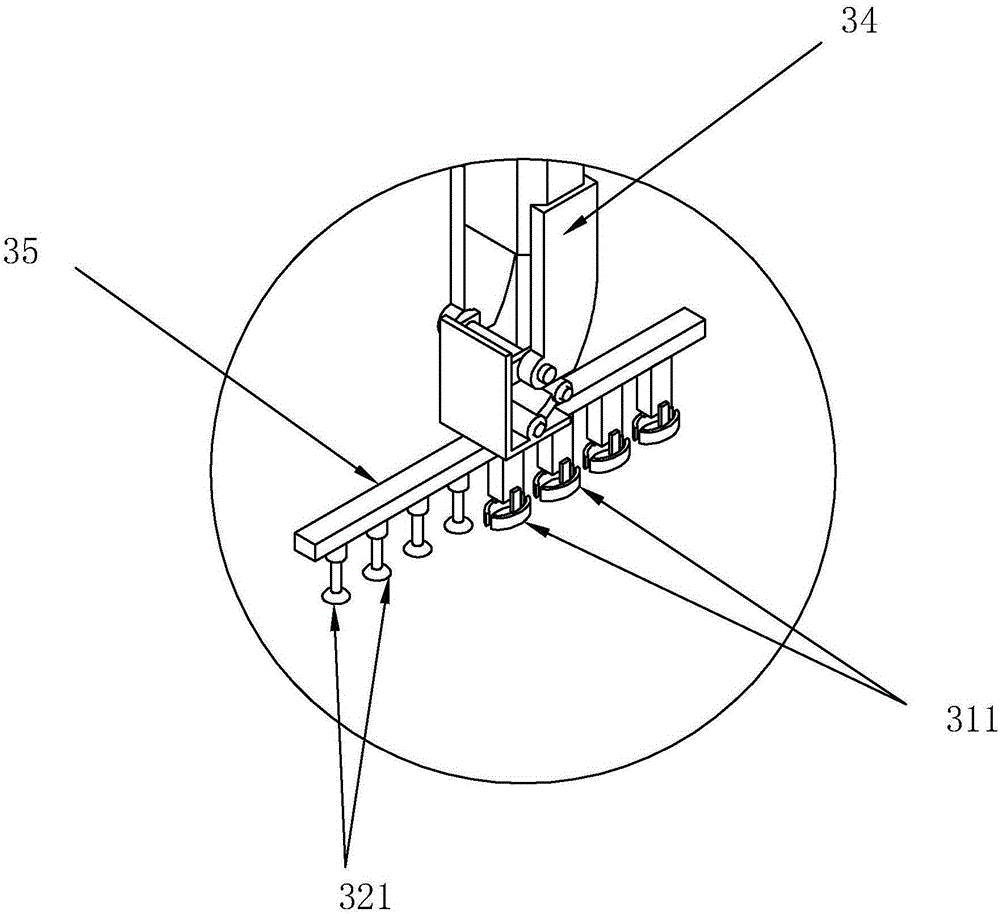

[0027] refer to Figure 1 to Figure 11 The embodiment of an automatic insert injection molding machine of the present invention will be further described.

[0028] First of all, it needs to be explained that the present invention relates to the injection molding process of the bottle cap with an insert 8. The front and back of the insert 8 have holes of different sizes, and the large hole can be inserted by the ejector rod 2222. The mold 7 on the injection molding machine 1 of the present invention adds two oil cylinders to complete the demoulding of the product and the reset of the template, reducing the action of manual mold clamping and then opening the mold 7, shortening the production cycle, and it is more common to use oil cylinders to demould technology, which will not be repeated here. Simultaneously, there are also fixed rods that can be inserted and fixed in the 8 large holes of the inserts in the 7 cores of the mold.

[0029] The present invention is an automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com